| [ Total Views: 34962 | Total Replies: 375 | Thread Id: 98668 ] |

| Pages: 1 .. 8 9 10 11 12 13 |

|

|

roverv8bay roverv8bay

Officially Full-On Dubber

Posts: 250

Threads: 32

Registered: January 30th, 2013

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 11th, 2014 at 07:11 AM |

|

|

G'day Vlad this as turned into a very informative thread maybe need to build a thread separate on what to look for & how to rectify. 10 years ago

when I did the mates EJ20 turbo into his syncro there was no on line help after several weeks of driving it daily it would go into limp mode finally

after back tracking I found 2 green & black wires 1 was for the VSS the other cruise control changed the wires over & never looked back. for

people wanting to have ago at doing their own a separate thread put together from members like yourself would be a great investment on the site. My 2

bobs worth

ernie

|

|

|

Joel Joel

Scirocco Rare

Now containing 100% E-Wang

Posts: 9368

Threads: 211

Registered: February 14th, 2006

Member Is Offline

Location: Northern Rivers NSW

Theme: UltimaBB Pro Purple

Mood: Tact Level 0.00

|

| posted on August 11th, 2014 at 02:41 PM |

|

|

Sorry Paul I feel like I'm totally hijacking your post here.

| Quote: | Originally

posted by vlad01

Joel, what does the Suby use for the crank trigger? its it a reluctor or haul effect sensor? I can't recall but seem to think it was reluctor?

|

I cant vouch for the later stuff with variable valve timing but earlier ones like mine the crank and cam are just hall effect.

I didn't realise how much you tooled around with ECUs, I did have a 3rd one but i chucked it out as it threw a constant purge solenoid fault I would

have sent it to you to have a play with.

Are aftermarket ecu much hassle to get dialed in?

a mate messaged me last night he has a couple of motec ecus I can fiddle with, I normally just stick to stock management for the plug and play factor.

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 11th, 2014 at 07:32 PM |

|

|

joel

no worries ,if threads take a little detour .I am happy to learn new stuff. I have still been getting the answers to the questions I asked and

moving ahead.

made progress on weekend

- IAC really cleaned out

- PCV was clogged,think i fixed it but still got a new one

- got a new coolant temp sensor

- bought some SA459 wil give that a go

I will aim this weekend to put it all back together and see if that has fixed the high idle

|

|

|

vlad01 vlad01

Compulsive Aussie Vee Dubber

Posts: 4270

Threads: 109

Registered: June 3rd, 2010

Member Is Offline

Location: Kyneton, VIC

Theme: UltimaBB Pro Blue ( Default )

Mood: Side ways

|

| posted on August 12th, 2014 at 04:36 PM |

|

|

| Quote: | Originally

posted by Joel

Sorry Paul I feel like I'm totally hijacking your post here.

| Quote: | Originally

posted by vlad01

Joel, what does the Suby use for the crank trigger? its it a reluctor or haul effect sensor? I can't recall but seem to think it was reluctor?

|

I cant vouch for the later stuff with variable valve timing but earlier ones like mine the crank and cam are just hall effect.

I didn't realise how much you tooled around with ECUs, I did have a 3rd one but i chucked it out as it threw a constant purge solenoid fault I would

have sent it to you to have a play with.

Are aftermarket ecu much hassle to get dialed in?

a mate messaged me last night he has a couple of motec ecus I can fiddle with, I normally just stick to stock management for the plug and play factor.

|

Yes looked into efi for long time. But couldn't get my head around the aftermarket units. Too much proprietary licensing cost and big $$ for tuning.

I originally wanted to go ms3 path for running a v6 Buick but in my pursuit for hardware I stumbled across the powerful stock delco units and stock

ecu hacking and tuning really got exciting.

Most stock ecus are hackable. But the important thing I learned is no aftermarket ecu even comes close to the highly developed code that is factory.

Manufactures spent decades and 100s millions developing this stuff. The code is going to be better than aftermarket. The only thing is having minds

capable of hacking and harnessing the capabilities of stock units

In all honestly I don't think I'll ever bother with aftermarket units just because they limited in function. Anyway going to the suby crank sensor.

Hall effect sounds good. Delcos use them as standard. I think it's possible to use a Bosch ignition module from camira. Or maybe one of me homies

developed universal ignition modules and run individual coils and then I can configure what ever crank trigger I like via software.

71 notchback,

Past owner of, 70 NB, 73 SB and 72 FB TLE |

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 18th, 2014 at 11:13 PM |

|

|

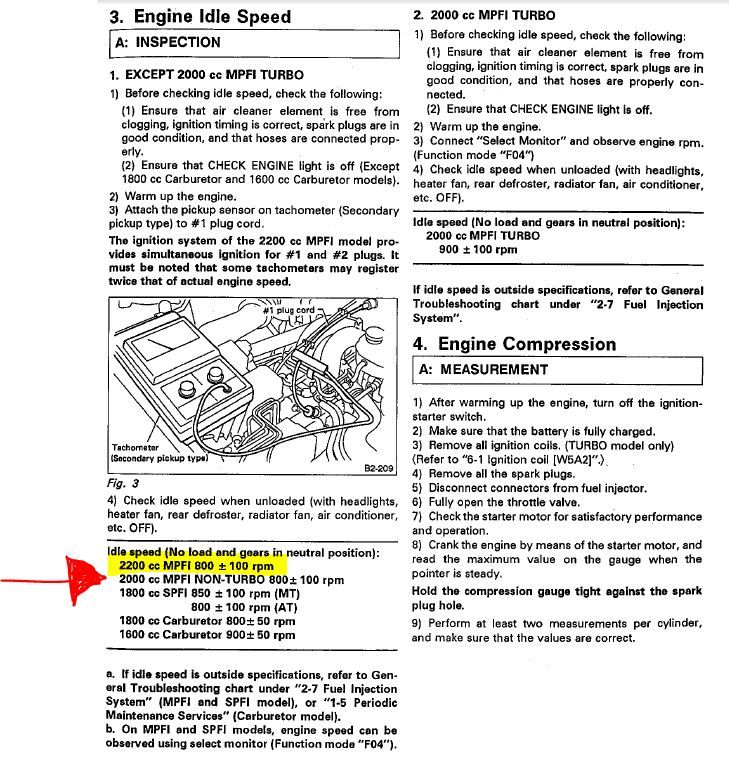

IAC resting state? ope ? closed or partially open?

who knows what about the IAC resting state? open ? closed or partially open?

I think i have the cooling now sorted, I just have a high idle 950 rpms. It does not vary much although seems to go higher when it is real warm.

It is a smooth idle . Not a varying one as per a vacuum leak

am I right it should be possible to get it to idle at 750rpm?

So I took IAC and hoses apart , the coolant sensor impedance was out of range although it did vary with hot water. I still replaced it.

I found the PVC valve was rusted shut , so I replaced that.

My throttle body screw looks ok , still has white paint on from the factory

accel cabel looks ok

throttle body looks clean inside. I then took the IAC out cleaned it all out. I marked the body so I can put it back together same way. I did take

the top of the magnet , it moved nicely and freely.

reinstalled all now have codes

12 - starter switch

22 knock sensor

23 Airflow sensor

24 air control valve

Looks like I fixed the coolant one

I did replace the knock sensor , I will check it again

-what do u think about starter switch code?

i checked there is battery voltage at the IAC. I then whilst engine running loosened the 2 screws on the IAC and I was able to rotate the IAC , I

got the engine to reduce to 850rpm nicely down 100 from 950rpm.

I don't know what is the resting state of the IAC, is it possible is out of range and the ECU cant close it? I am sure when I pulled it out the

back vane was open.

I was thinking pulling it apart again rotating the shaft so the back vane is just closed.?

I was guessing when warm, the ECU closes the vane and when cold it opens for more air

I read you don't normally adjust like a carby the ECU does it but I am wondering if it is out of range.

|

|

|

Joel Joel

Scirocco Rare

Now containing 100% E-Wang

Posts: 9368

Threads: 211

Registered: February 14th, 2006

Member Is Offline

Location: Northern Rivers NSW

Theme: UltimaBB Pro Purple

Mood: Tact Level 0.00

|

| posted on August 19th, 2014 at 08:14 AM |

|

|

Hi Paul, dont worry too much about the vane position when the engine is off, it will correct it as soon as you turn the igntion on.

They are always open a bit initially, that is why fuel injected engines rev up on their own then settle back to idle when you first start them.

as long as the screws for the iacv top motor arent all the way to one side of the slots its set right,

mine are biased more to the clockwise direction though.

one thing to consider is the ecu will bump the idle up if there is a fault detected with various parts like air flow meter, throttle position senser

etc.

Also double check for vac leaks, there is a lot of unused manifold vac ports for cruise control, climate control, brake booster, purge solenoid etc in

an engine conversion which may have got left open.

the starter switch is a common one in conversions as it gets forgotten about.

a wire from the ecu needs to be piggybacked to the starter wire so the ecu knows you are cranking and it alters the timing for easier starting.

the knock sensor may take some time to sort itself out.

When I replaced mine it took 10mins of driving before the computer realised and the code stopped

|

|

|

vlad01 vlad01

Compulsive Aussie Vee Dubber

Posts: 4270

Threads: 109

Registered: June 3rd, 2010

Member Is Offline

Location: Kyneton, VIC

Theme: UltimaBB Pro Blue ( Default )

Mood: Side ways

|

| posted on August 19th, 2014 at 10:52 AM |

|

|

shouldn't the ECU immediately give the ok with knock sensor? after all they do have a shunt resistor internally so the ECU knows if its connected and

functioning correctly.

71 notchback,

Past owner of, 70 NB, 73 SB and 72 FB TLE |

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 19th, 2014 at 09:27 PM |

|

|

I guess we llike a challenge

Joel

It has me a little intrigued , this IAC

Is there a better book than the haynes? is there a bentley like for VW , they are good

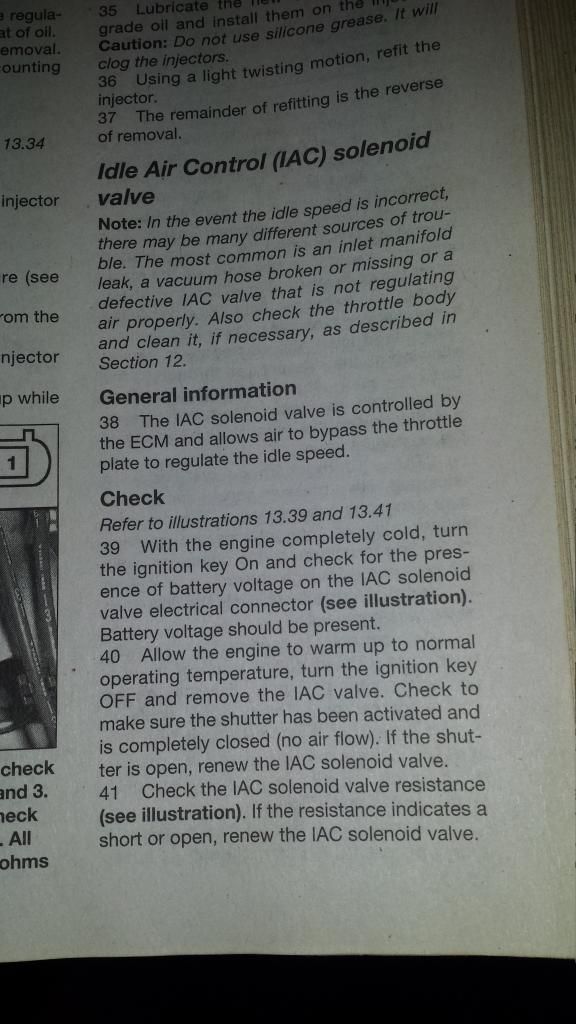

haynes does not explain enough, it says when the IAC is removed the vane should be closed otherwise it needs to be replaced!

So I interpret this as the back vane is normally closed without any ECU power. Engine running, The ECU would apply voltage and open and close it

with some type of duty cycle

I am going to kick myself if i find it is some small vacuum leak

please remind me again- I have a constant idle 950, it does not hunt or vary too much. it may change with engine

I thought a vacuum leak means they idle will hunt or swing noticably??

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 19th, 2014 at 09:34 PM |

|

|

I meant to say -- I have a constant idle 950, it does not hunt or vary too much. it may change with engine temp, as it warms up

|

|

|

Joel Joel

Scirocco Rare

Now containing 100% E-Wang

Posts: 9368

Threads: 211

Registered: February 14th, 2006

Member Is Offline

Location: Northern Rivers NSW

Theme: UltimaBB Pro Purple

Mood: Tact Level 0.00

|

| posted on August 20th, 2014 at 12:12 PM |

|

|

Admittedly I've only dealt eith gen1 IACV but none of them were spring loaded, the vane just freewheels with no resistance.

Is your check engine light constantly on?

as you are gettin AFM fault im wondering if its just the ecu bumping the idle up in safe mode.

as for manuals I dont have any paper oned, ive just got a PDF subaru workshop msnual somewhere on file.

I can email it if I can find it, ( might have got lost in a harddrive crash)

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 20th, 2014 at 10:54 PM |

|

|

cel is on

Joel

yes my CEL has those 4 codes still on

I think the starter switch may go away as I broke the ignition switch.

I am going to have another go this weekend, also really inspect for the faintest leak

that would be great if u did have a better Ej22 manual

|

|

|

Joel Joel

Scirocco Rare

Now containing 100% E-Wang

Posts: 9368

Threads: 211

Registered: February 14th, 2006

Member Is Offline

Location: Northern Rivers NSW

Theme: UltimaBB Pro Purple

Mood: Tact Level 0.00

|

| posted on August 21st, 2014 at 08:48 PM |

|

|

So you got it to clear all the codes?

The manual is proper Subaru workshop manual, the entire thing is over 900 pages.

I'm sure I have the zipped PDF of it somewhere but just need to find it.

You can get the indiviual chapters from here:

http://www.ausubaru.com/forum/showthread.php?t=7011

The chapter on fuel injection (2.7a) has a really good section on how to test and diagnose all the sensors.

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 22nd, 2014 at 08:15 PM |

|

|

thats gold

Joel

that great, I will use that site a lot

I found the haynes just does go into enough detail

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 22nd, 2014 at 08:18 PM |

|

|

I found the haynes just does not go into enough detail

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 22nd, 2014 at 08:53 PM |

|

|

Where was it when I needed it?

Joel

that manual is great, craps on Haynes

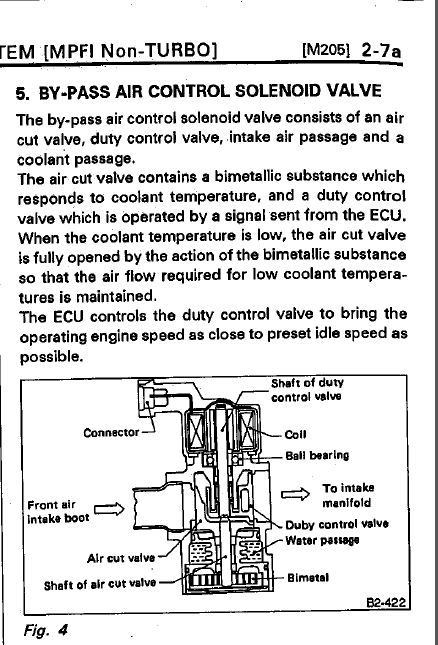

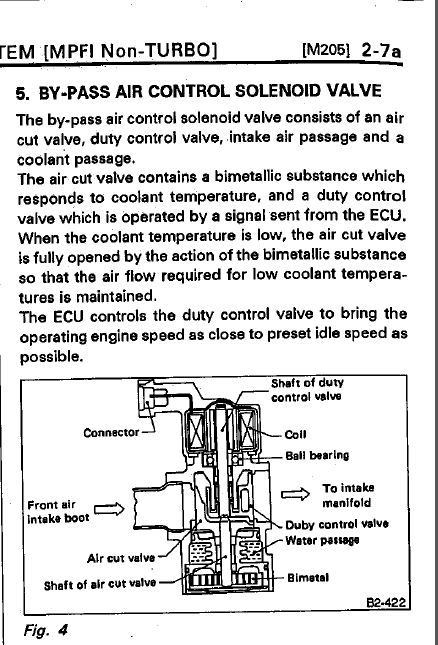

They don't call it an IAC instead a Bypass Air control valve. Now it makes a lot more sense that it mentions it has a Bi-metallic strip in

side. It reacts with hot coolant to close it .

Now I understand the simplistic instructions in Haynes

Once the engine coolant is warm this IAC valve when removed should appear to be closed.

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 23rd, 2014 at 11:01 PM |

|

|

One step forwards 2 sideways?

well with all the Rain it was hard to work on sunnyjim out In the open

But I progressed.

I managed to install the oil pressure Sender. Not as easy as l first thought and in the end l took the cutting disk to the Steering pump /

alternator stand

I still have 4 cel Codes. I removed the the IAC again. Dismantled and it looks to move nice and freely. I thought I could adjust the top magnet so as

to close the back vane but still no luck. I then thought as it has this magical bi-metallic strip I will boil it up in a pot of wat er and watch the

vane close. But still no change

So l really havent proven anything. haynes says when the engine is up to temp if you remove the IAC the back Vane should be closed. Mine was still

open. Is it faulty?

according to the book it is. l wish I had another one to substitute

I loosened the 2 IAC screws and reduced the RPMS to 850 rpm but it needs to go 750

the kombi wins this round today.

I still havent proven if I have a good or bad IAC valve

|

|

|

Joel Joel

Scirocco Rare

Now containing 100% E-Wang

Posts: 9368

Threads: 211

Registered: February 14th, 2006

Member Is Offline

Location: Northern Rivers NSW

Theme: UltimaBB Pro Purple

Mood: Tact Level 0.00

|

| posted on August 24th, 2014 at 12:27 PM |

|

|

Hi Paul,

the Subi manual says to check the ohms on the stepper motor so see if that electrical side is ok.

if you remove the plug there is 3 terminals in there, if you put one probe on the middle one then check the ohms from both sides they should both read

9ohms if its ok.

I have got the old IACV off my bug if you want to try it out.

It was from my original motor which was destroyed internally from electrolysis due to lack of coolant changes.

It has worked fine on my bug for the last 5 years but I replaced it as the coolant lines were getting a bit crusty from the electrolysis.

I wouldnt rely on it long term but its in working order if you want to try it out.

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 25th, 2014 at 09:44 AM |

|

|

Thanks joel- can u check a couple of things for me pls?

Joel

that is a kind offer that I may take you up on soon.

I checked the resistance , as you say 9 ohms on both sides.

I also thought , could I have put the magnetic shaft back on wrong? So I tried it but putting it on wrong is almost impossible. I held the vane

closed then slid the top cover with magnets back down. The magnets pull the vane back to half to 3/4 closed- a predetermined position.

Should the back vane fully close when coolant is at 100 degrees ? This would be due to the bimetallic strip. Could you check this for me? Haynes

said "Run the engine up to op temp , then remove the IAC , The back vane should be closed, if not replace the IAC." if it closed without power to

it then I assume it doesn't need a ECU signal to do this , it is just the coolant temp doing it . If you could boil the bottom half of that IAC up

does the back vane close or not? Mine doesn' t .

The other simple l thing I have not tried yet , should have thought of it previously is to remove the large hose from the IAC and block both ends

off. No air can get through that back vane, . I assume this is like having the vane closed. engine warm, if my idle comes down to 700-750 that

proves it is the IAC.

|

|

|

vlad01 vlad01

Compulsive Aussie Vee Dubber

Posts: 4270

Threads: 109

Registered: June 3rd, 2010

Member Is Offline

Location: Kyneton, VIC

Theme: UltimaBB Pro Blue ( Default )

Mood: Side ways

|

| posted on August 25th, 2014 at 09:52 AM |

|

|

| Quote: | Originally

posted by Sunnyjim

Joel

that manual is great, craps on Haynes

They don't call it an IAC instead a Bypass Air control valve. Now it makes a lot more sense that it mentions it has a Bi-metallic strip in

side. It reacts with hot coolant to close it .

Now I understand the simplistic instructions in Haynes

Once the engine coolant is warm this IAC valve when removed should appear to be closed.

|

Wow! what a crazy contraption! Seems like a ridiculously long winded way going about something simple a normal IAC can more than do.

71 notchback,

Past owner of, 70 NB, 73 SB and 72 FB TLE |

|

|

Joel Joel

Scirocco Rare

Now containing 100% E-Wang

Posts: 9368

Threads: 211

Registered: February 14th, 2006

Member Is Offline

Location: Northern Rivers NSW

Theme: UltimaBB Pro Purple

Mood: Tact Level 0.00

|

| posted on August 25th, 2014 at 01:29 PM |

|

|

They are an absolutely horrid design, they only used them on early Liberties, the 96ish onwards ones are ecu controlled only no coolant.

They never close up completely, the engine wouldnt idle otherwise.

the throttle butterfly completely closes, at idle the IACV is the only source of intake air.

Paul the one on my bug is a nightmare to get at but I had a play with the spare one.

stone cold the back coolant valve was 3/4 open and kept returning to that spot when moved.

with boiling water through it after 5 mins or so it closed a little maybe half way but that was it.

strangely even after an hour cold it still hasnt moved back.

I did get some pics but they are too hard to upload here from my phone.

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 25th, 2014 at 05:25 PM |

|

|

please send

Joel

Thanks for your help. If you can loan me that IAC I am happy to pay for post to and from.

The way you are describing yours it doesnt sound that different to mine but it will help me confirm

Although I got codes I am surprised that my idle is still in range according to the specs below range 700 to 900 rpms.

l have rotated the IAC anticlockwise and got the RPMS to reduce to approx 830 to 850

I think a 700 to 750 is ldeal

I have to keep checking and solving the codes ie..not to sure how a knock sensor increases idle. For instance l dont understand how the ECU thinks. Is

it possible the ECU bumps up idle on various non IAC codes?

|

|

|

Joel Joel

Scirocco Rare

Now containing 100% E-Wang

Posts: 9368

Threads: 211

Registered: February 14th, 2006

Member Is Offline

Location: Northern Rivers NSW

Theme: UltimaBB Pro Purple

Mood: Tact Level 0.00

|

| posted on August 25th, 2014 at 06:22 PM |

|

|

No dramas, I'll sort it out with you.

I keep my idle bang on 800 like the specs say, I found any lower causes it to hunt up and down.

WHen it says the valve should be shut its only talking about the outer coolant controlled one, the ECU controlled inner valve does its own thing and

stays slightly open whereever the magnetic force keeps it as you found out.

| Quote: | Originally

posted by Sunnyjim

Is it possible the ECU bumps up idle on various non IAC codes?

|

Absolutely, I know from experience it bumps the idle up for airflow meter and Throttle position sensor problems, mainly so the car is still somewhat

drivable without stalling.

If you can get yours to 800rpm without maxing out the controller postion in the slots I would say you dont have an issue.

When my old knock sensor gave up the ghost completly (had to do a Homer Simpsons, tape over check engine light, it was blinding at night) it didnt

bump the idle up but it definetly went into safe mode with the ignition timing.

could feel it holding back.

|

|

|

vlad01 vlad01

Compulsive Aussie Vee Dubber

Posts: 4270

Threads: 109

Registered: June 3rd, 2010

Member Is Offline

Location: Kyneton, VIC

Theme: UltimaBB Pro Blue ( Default )

Mood: Side ways

|

| posted on August 25th, 2014 at 06:43 PM |

|

|

| Quote: | Originally

posted by Joel

They are an absolutely horrid design, they only used them on early Liberties, the 96ish onwards ones are ecu controlled only no coolant.

They never close up completely, the engine wouldnt idle otherwise.

the throttle butterfly completely closes, at idle the IACV is the only source of intake air.

Paul the one on my bug is a nightmare to get at but I had a play with the spare one.

stone cold the back coolant valve was 3/4 open and kept returning to that spot when moved.

with boiling water through it after 5 mins or so it closed a little maybe half way but that was it.

strangely even after an hour cold it still hasnt moved back.

I did get some pics but they are too hard to upload here from my phone.

|

its crazy to think they would use 70s tech on 90s engine management?

IACs been full ECU controlled at least since early 80s for most cars. This is the first time I seen something like this so late in car evolution. Its

like a band-aid for limitations in ECU programing? How could of it been for them to add extra tables for coolant temp vs idle etc... ?

71 notchback,

Past owner of, 70 NB, 73 SB and 72 FB TLE |

|

|

Joel Joel

Scirocco Rare

Now containing 100% E-Wang

Posts: 9368

Threads: 211

Registered: February 14th, 2006

Member Is Offline

Location: Northern Rivers NSW

Theme: UltimaBB Pro Purple

Mood: Tact Level 0.00

|

| posted on August 25th, 2014 at 06:55 PM |

|

|

I can only assume it was someones idea of a safeguard if the temp sensor stopped working it will still idle up when cold.

This was all the outer valve did when boiling water was run through it for a while

edit, its put the pics in the wrong order.

| Error |

| Sorry, you must be a registered user in order to download attachments. |

|

| Error |

| Sorry, you must be a registered user in order to download attachments. |

|

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 25th, 2014 at 11:23 PM |

|

|

Airflow meter.

l will also try to reduce other sources of problems. I did the throttle position sensor and switch check, it was Ok

I will also go buy some proper stuff to clean the airflow sensor.

still wondering, although I really have cleaned the IAC well, is it still needed to run

SA459 down through the throttle body.?

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 28th, 2014 at 05:07 PM |

|

|

thx joel

Joel

really appreciate the quick loan of the IAC, it means I can install and test this weekend

At first sight they look just like identical twins . The back vane both seem the same gap and spring back nicely. well slight difference in gap

because I have rotated mine a bit more to reduce the idle speed.

My prediction this helps me confirm the IAC is not the issue and I need to keep searching to solve those Codes.

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 30th, 2014 at 08:08 PM |

|

|

Beaut day in Brisbane.

the Brizzy weather was magnificent today. Resisted the temptation to drive to the GC and cleanse my skin with saltwater. Instead covered myself in

kombi grease.

So l got stuck right in. Joel's loan IAC valve arrived earlier in the week. I installed it. Now at first I thought I might be on a winner, as for a

minute I saw the revs sit. at 700 or so. But no, l sense the ECU bumped it up to about 850 rpm. Same as before . So I can conclude the IAC value is

not the issue.

Joel- thanks, you have saved me going on a wild goose chase, as new IACS are $700 upwards.

l bought proper airflow sensor cleaner, did that. Cleaned the throttle body out and also poured the legendary SA 459 through the upper engine. I think

it was doing its thang as it was coughing and spluttering. What did I get in return for all this hardwork? I got 5 codes.

12 starter

22 Knock sensor

23 Airflow sensor

24 Air control valve

31 Throttle sensor

l wish l knew how the ECU thinks.

Some codes have come and gone but the code 22 has been here all along the knock sensor.

original was cracked so I replaced it.- the book says check for short circuit. Nope it is about 880K ohms. but I am not happy, it doesn't seem to

click into the electrical connector . Can it be ol' knocker sensor is causing all this trouble? So I totally disconnected it and still no

difference.

Does anyone know what should happen with a knock sensor disconnected?

Due to the way knock knock sensor is located I am not 100% sure it Is connected

Need to follow that up

Something tells me I better get a life . Am I becoming Kombi obsessive compulsive?

|

|

|

chellejohno chellejohno

Slammed & Awesome Dubber

Posts: 78

Threads: 7

Registered: February 3rd, 2011

Member Is Offline

Theme: UltimaBB Pro Grey

|

| posted on August 30th, 2014 at 08:23 PM |

|

|

Geez mate I feel for ya. Nothing worse than chasing issues like these, youre a more patient man than I am that's for sure.

You'll sort it, just a process of elimination, just like your doing.

If I start having the same dramas, I'll be moving my thread to the for sale section!

|

|

|

Sunnyjim Sunnyjim

Officially Full-On Dubber

Posts: 239

Threads: 5

Registered: January 15th, 2010

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on August 31st, 2014 at 09:42 PM |

|

|

chellie thanks for the encouragement

As long as feel I am not at a dead end I feel I can keep going. I would now rather be driving it. I am a little embarrassed l may be recognized for

the longest time to complete a conversion !

I suspected for a while now that the Issues from codes might not still exist, then I read below and it says removing power is not enough to clear

codes. There is a process to go through. A couple of weeks ago l replaced my lghition switch and I am sure that is how I got code 12 . The car starts

good, no Issue with starting so that code should have cleared.

Next step is to follow the process and see if I can dean some of these codes.

http://www.weidefamily.net/vanagon/HTML/05/01/01/03.html

|

|

|

vlad01 vlad01

Compulsive Aussie Vee Dubber

Posts: 4270

Threads: 109

Registered: June 3rd, 2010

Member Is Offline

Location: Kyneton, VIC

Theme: UltimaBB Pro Blue ( Default )

Mood: Side ways

|

| posted on September 1st, 2014 at 11:50 AM |

|

|

| Quote: | Originally

posted by Sunnyjim

the Brizzy weather was magnificent today. Resisted the temptation to drive to the GC and cleanse my skin with saltwater. Instead covered myself in

kombi grease.

So l got stuck right in. Joel's loan IAC valve arrived earlier in the week. I installed it. Now at first I thought I might be on a winner, as for a

minute I saw the revs sit. at 700 or so. But no, l sense the ECU bumped it up to about 850 rpm. Same as before . So I can conclude the IAC value is

not the issue.

Joel- thanks, you have saved me going on a wild goose chase, as new IACS are $700 upwards.

l bought proper airflow sensor cleaner, did that. Cleaned the throttle body out and also poured the legendary SA 459 through the upper engine. I think

it was doing its thang as it was coughing and spluttering. What did I get in return for all this hardwork? I got 5 codes.

12 starter

22 Knock sensor

23 Airflow sensor

24 Air control valve

31 Throttle sensor

l wish l knew how the ECU thinks.

Some codes have come and gone but the code 22 has been here all along the knock sensor.

original was cracked so I replaced it.- the book says check for short circuit. Nope it is about 880K ohms. but I am not happy, it doesn't seem to

click into the electrical connector . Can it be ol' knocker sensor is causing all this trouble? So I totally disconnected it and still no

difference.

Does anyone know what should happen with a knock sensor disconnected?

Due to the way knock knock sensor is located I am not 100% sure it Is connected

Need to follow that up

Something tells me I better get a life . Am I becoming Kombi obsessive compulsive?

|

farrrk!!!!! what a price!

71 notchback,

Past owner of, 70 NB, 73 SB and 72 FB TLE |

|

|

| Pages: 1 .. 8 9 10 11 12 13 |