[img]

[/img]

[/img]Matt.

Workbenches!

I am about to make 'The Bench'

It is my third ever. The last one lasted 12 yrs, I gave it to a mate as it was too big for new workshop. I usually end up with 2/3rds of it covered

in crap. I have a toolbox on a stand . I want to store socket sets, torque wrench, timber tools etc in drawers for easy access and tidying up.

Needs to take an engine on top of it, timber work, be high as I am tall, solid so I can thump something in the vise.

I have the spot for it with overhead power, light and air.

Plan

about 1200wx800dx1100h

pine mpg10 90x35 frame (what I have stored under my floor)

recycled hardwood top (got that too)

benchvice (and that)

I am building it as a free stander so I can move it if need be. I am going to put lotsa metal runner drawers in it and a few shelves.

I will have an open tray under one side for oil can, spray lube, crc, grease, aerostart etc. I have a rag on a roll dispensor lined up and a bin. I

have tunes.

What other tip tips or bright ideas do others have?

kkk

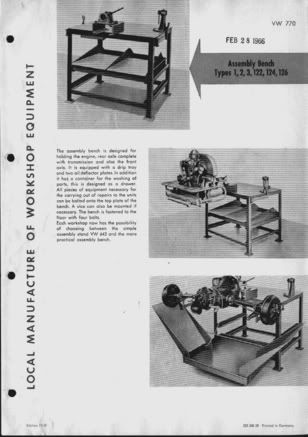

As well as a bench vice (very useful) I would add the provision for a bolt on bolt off bench mounted VW enguine stand. Again very useful. But needs to be unboltable for when you need the space back.

If you are going to do a lot of engine/mechanical work on the bench I suggest that you cover the top with a sheet of galvanised iron. It makes it indestructable and cleanup is really easy. I also suggest a strip of wood about 150mm high attached to the full length of the back of the bench to prevent things from falling down behind the bench.

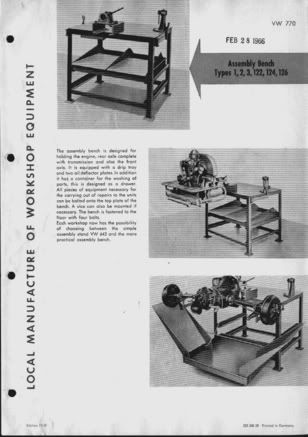

What about this? Genuine 1960's VW factory designed workbench. I caan send you blueprints.

[img] [/img]

[/img]

Matt.

how cool is that^^:thumb

| Quote: |

I built my bench out of salvaged scrap. Got some guardrail post offcuts (steel) from roadworks nearby, welded them together into a 1300 long frame, about 550 deep. Made the top out of some 35mm a-grade pine plank that I had sitting around, and a tall pegboard back for my most used tools. It's as heavy as a piano and you can belt the crap out of anything on it. Got 150mm engineering multi-pivot vice bolted to one end with 12mm grade8 bolts. Bloody good bench with a total cost of bugger all.

My tight arse nature says that I build this out of what I have to hand. The only expense so far is going to be a sheet or 12mmply for the drawers and

the metal runners, although shelf drawers dont need a faceplate and runners take up space.

Type one I have an engine stand that I made that dynabolts onto a house stump (queenslander) or wall. I love that bench idea but dont have the

space.

The hardwood flooring I have is very very hard, varnished, isnt absorbant.

I will have a 50mm lip on the front to clamp off and a lip on the back. I had a 150 wall plate on the last bench, good idea but I want the opion of

360 work if I need so I will put a bead along the back.

Plans coming.....

h. Yes indeed. All proper workshops have a comfy chair.

| Quote: |

got tv got chair (s)

any other ideas from the more mechanically inclined, recreations are covered!

Put it on wheels/castors with Brakes