You can look at some of the pics of my ex-Shimo blow through setup at:-

http://www.matara.net/gallery/Turbo

Cheers

Steve

I am thinking seriously of a draw through turbo for a 1640 I am in the process of putting together. I would appreciate any pics or info that might

help me make an informed oppinion.

I have spent a lot of time searching the samba and shoptalk forums and reading anything i can get my hands on, so I don't think i'm not jumping in

with my eyes closed.

Please, no posts on "forget the turbo and go a 1914" or go a rotary or subi motor, not gonna happen.

I have access to good machining and fabrication facilities and this is something i've always wanted to do.

I'd rather do it the right way than the wrong way and I know for a fact after visiting some other forums, some of you guys are pretty switched on to

turbo's.

I pulled the engine out of my car on Monday but it's not going to be a short term project. If there's an interest i'll post some pics as I go. If

it all turns to shit I'll just whack some carbs on it.

Cheers & let the games begin

[ Edited on 4-5-2006 by Stanley ]

[ Edited on 9-7-2006 by Stanley ]

[ Edited on 6-10-2006 by Stanley ]

[ Edited on 6-10-2006 by Stanley ]

[ Edited on 17-12-2006 by Stanley ]

[ Edited on 28-12-2006 by Stanley ]

[ Edited on 8-1-2007 by Stanley ]

[ Edited on 8-1-2007 by Stanley ]

[ Edited on 15-1-2007 by Stanley ]

[ Edited on 28-1-2007 by Stanley ]

[ Edited on 10-2-2007 by Stanley ]

[ Edited on 12-2-2007 by Stanley ]

[ Edited on 19-2-2007 by Stanley ]

[ Edited on 5-3-2007 by Stanley ]

[ Edited on 24-4-2007 by Stanley ]

[ Edited on 20-5-2007 by Stanley ]

[ Edited on 1-6-2007 by Stanley ]

[ Edited on 15-6-2007 by Stanley ]

[ Edited on 19-8-2007 by Stanley ]

[ Edited on 28-9-2007 by Stanley ]

[ Edited on 30-9-2007 by Stanley ]

You need to think about building a bulletproof bottom end, loweing your compression ratio, where your going to mount your carb (if your goin draw

through then its going to be a DHLA or DCOE), what size turbo you'll need and do you really want to do all that fabrication and suffer lag of a

draw through setup?

You can look at some of the pics of my ex-Shimo blow through setup at:-

http://www.matara.net/gallery/Turbo

Cheers

Steve

i would say go the blow thru route, alot of people will tell you that you can't blow thru a carby but with a webber you can run up to 13psi without

mods and with a dell you can run more. if you want to go fancy, fill your float bulb thing with like expanda foam to stop it crushing and build a

sealed box around the carby, like a big phlem that covers the whole carby with a seated fuel line etc and then just blow the pressure into the box.

this stops the carby leaking out the bottom cause of the pressure is equal inside and out of the carby and also the carby works properly due to the

fact that they read pressure difference and they can work better when setup like this. hope this helps. if your running twin carbies i would like to

see the set up cause im looking at doing the same thing but with a supercharger on a 1916.

good luck

Thanks guys.

I hear what your saying and have put some thought into that very question. I've read the pro's and cons on both, but I think for me and the budget,

draw through is the easiest way. i know lag is an issue but i'm not after a huge power increase and I can forget about elec fuel pumps and regulators

and sealing carbs. Only have to either find a turbo with carbon seals or get one resealed.

however this is not set in stone.

Matara, i have looked at your photo's and that is a neat set up and well hidden. You wouldn't know what was lurking at first glance.

ahhh...bajaben....nothing like the sound of a supercharger, id be interested in what you had in mind.

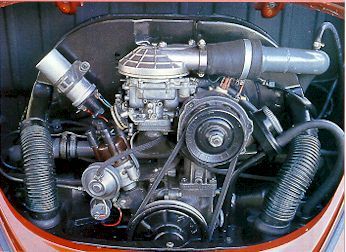

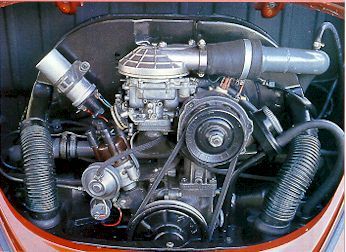

just another pic of another engine, but hopefully the start of something

Andrew,

sounds like an interesting project.

The latest Hot VWs mag has the details about modifying a holley for turbo use, but is a little bulky to keep under the decklid.

The SU carb and the Japanese copies from Hitachi I think, are very compact, cheap, and forgiving regarding air flow and fuel delivery, so

you might like to google that option for turbo or draw thru blower use.

Except that I am unsure about availability for your application, a centifugal blower and draw thru SU style carb would make for a neat set

up and be easyer to convert back to N/A should you have a prob or decide to change something. IE same exhaust, just the intake system and pulleys

would be different.

Lots to think about, and just a pulley change to get the boost you want for any given engine size.

There is no necessity to bother boxing up carbs for blow-thru setups. That kind of setup is very old school and that box arrangement went out with the

ark.

Some simple air pressure seals work perfectly and are cheap and easy to set up for. I wont bother with an explaination on them here.

It sounds very much like you want a real budget setup given you dont want to outlay for a second hand EFI fuel pump and a boost pressure sensed fuel

pressure regulator. A grand total of about 200 dollars at most in order to successfully blow thru.

Draw thru setup will work ok but the financial corners you are proposing to cut are barely a bend in the actual setup road!

I have run both pull thru and blow thru setups on exactly the same engine and there is little comparison.

The difference is worth so much more than a few lousy couple of hundred dollars you will spend on your pressure pump and regulator.

I would suggest you hunt around and source a pair of single throat Solex blow thru turbo carbs or the equivlent Weber variant. These carbs come with

throttle shaft seals to begin with and heavy duty floats to guard agains float collapse under higher boost pressures.

This way, you can avoid all the common hassles of long manifolds under the carb and attendant fuel condensation that will drive you mad after a couple

of cold winter nights drives.

It also gives you the option of adding an intercooler to your setup.

Its a no brainer really when comparing suck and blow but sourcing the turbo carbs is getting a little harder now as they are pretty old school now.

However, there are quite a few of the older Daihatsu Charade Turbo engines laying around that used a 2 bbl carb with boost enrichment circuits.

I have pulled thru bothe center float (HIF) and side float 45mm SU's and blown thru HIF SU's and the Solex turbo carb.

The SU was far superior to the Solex in all respects and there are a couple of stock needles and springs that will do the job nicely.

I spent hours hand shaping different needles but found it very hard to improve on the standard turbo needles. From memory, they are marked BCA and a

BAD. One was a fair bit more aggressive in its fuel delivery and suited a much hairier setup.

On a beetle engine, SU's will not be much use in a blow thru arrangement as the SU's require a fairly large plenum in front of them to work at all

in blow thru arrangement.

The Webers and Solexes are almost identical to look at compared to something like a 36Hp PCI carb. They have the same stud mounting setup but I have

not compared them to see if they are a bolt up.

Blowing thru a pair of carbs will improve throttle response right out of sight not to mention the almost halved boost lag time and will do away

entirely with the drama of fuel condensation issue. believe me, its a pain in the arse and the effort of the blow thru conversion alone was worth it

in terms of driveability alone..

The cost of an old EFI pump and a new FPR is negligable compared to the gain in day to day friendliness of a carbed turbo engine.

Pull thru arrangements are only really any good when they are setup on a non-crossflow engine such as a Ford or Holden six where the inlet tract

length is very short. Of course they will work in any application if you can be bothered with the side effects of long inlet runners (fuel

condensation, soggy throttle response, greatly increased boost lag and so-on) but to eschew a blowthru setup based purely on the price of a high

pressure pump and fuel pressure regulator is foolish.

You will save more than that in the snails carbon seal conversion alone!

For a mild setup, consider a Turbo off a Pulsar Turbo ET (To2) or something like a RHB5 IHI and the like offen some older 1600 (odd) CC 80's Jap

turbo iron. These turbos will boost you ride happily to about 12 to 14 psi (intercooled or water injected) all day, which will lift you Kraut's

performance nicely

Expect to pay around between 80 and 120 bucks for a To2. I have never paid more than this for the 5 of them I have here!

Happy turboing dude. You will enjoy the challenge of it and the benifits and fun factor outweigh the cost factor by a long shot!

L8tr

E

[ Edited on 13/4/06 by tassupervee ]

Have a look at AJ Sims turbo kit over at http://lowbugget.com/1600t.html.

This is as basic as you can get, draw through and onto a stock 1600cc.

Could be good fun!

Cheers

Steve

Thanks for the imput guys

after tsv's input i will do some more homework and give the blow through some more thought. Matara's set up looks so neat so there's another

reason.

Got the engine torn down y'day so will clean it up over the weekend and drill and tap it for the full flow oil system then drop it over to CE for

some case savers. Will pick up my heads while i'm there.

As the 1500 had a standard shroud and cooler i'll need to get a bracket for the oil cooler to fit the dog house. Kicking my self now, Up till 2 weeks

ago I was going to sell it, so I started to get rid of bits and pieces. Got rid of a complete dog house cooler set up and a set of Kads and dual port

tinware. If anyone has any thing lying around let me know.

thanks again...post any pics which might help

I read the following article a while ago in VW trends.

I hope this helps

http://www.vwtrendsweb.com/tech/0211vwt_turbo/

http://www.vwtrendsweb.com/tech/0211vwt_turbo02/

John

I'd offer you the kaddies back Andrew but I have something similair in mind as per someone else in this thread.

Just a quick update in case you all thought I was a "gunna"

heads are finished and have been CC'd...thanks Craig

I took the case into CE for some machine work...case savers and an aliign bore and some other minor stuff..thanks again Craig

Was glad to find it was a duel relief case. Just need to drill and tap for full flow oil.

This will go with the eight dowelled crank, 12lb flywheel, reground cam I allready have in stock.

Also thanks to my wife for buying me the Turbomania book for my birthday...i'm sure she thinks this is just a fad......

Just doing some homework in the meantime on the turbo set up. Thanks for the advice and I did think long and hard but have settled on a draw through.

This will not be a daily driver so I will push the envelope a bit, however it won't be hand grenade waiting to go off. All the running gear is

stock. Just something to have some fun with.

If it looks half as good as this i'll be happy.

oh snap!

nice man

nick

just a quick update. The machining is done and will be picked up next week.

In the interim I managed to score this.

Has there been any progress on this yet ?

yep slowly

Got the last of the bits to get the short motor together.

Spent yesterday cleaning, cleaning and more cleaning. Both cases have been scrubbed and yesterday i gave them a final degrease and hit them with a

water blaster to clean out all the oil galleries after drilling and tapping for full flow. Then into the kero bath for more cleaning

spent today assembling the (8 dowelled) crank, fitting the bearings and trial fitting the crank and cam. Lucky I did as there was a dodgy tooth on the

crank gear that wouldn't allow 360deg rotation. Cleaned up the gear and put the other case half on and it spins nice.

Next weekend i'll pull the crank back out and fit the rods and get ready to seal it up....maybe......Rome wasn't built in a day.

What cam and lifters Andrew?

I think Craig said the cam was equivalent to a Scat C25 which should be .385in Lift X 275 Degrees Duration. May not be the best cam for what i'm

doing but I got this cam before I decided to add a turbo. Lifters are stock.

I'm also thinking about a removable rear apron...have to put some thought into that.

Was talking to the guys here at work, and they said the Turbo Sigma came

with a T04 and external wastegate, that also used a Hitachi draw thru setup.

Perhaps a trip to the wreckers to find those parts?

Exhaust housing is .48 apparently...good start.

That will work well that cam...!

Cheers Dave...Thanks

Well this weekend was 3 steps forward and two steps back.

My son found what was described as a rebuilt (read washed) airesearch m10 turbo from a nissan exa off guy at his work. Brought it home, and I don't

no a lot about turbo's but, i'm pretty sure the 2 big cracks in the exhaust housing from the waste gate aren't supposed to be there.

Anyway, put the rods on the crank and checked all the clearances, all good, and thought maybe I should replace the rod nuts. Nah she'll be right I

thought. Not being the most patient of people and wanting to get it togther in a hurry. (this motor has taken 5 years to get this far). Spent the rest

of the day washing everything up ready to mate the cases.

I had a set of lifters which, back when I pulled the engine down thought were great until I noticed the dish in the face you could drive a truck thru.

Will I or won't I. Luckily A good nights sleep let sanity prevail and tomorrow i'm off to buy some new lifters and some new rod nuts.

Maybe next weekend

Picked up some new lifters on Friday so I got the case halves together over the week end. All went together nicely.

Thought it was going to end in tears when I went to put the oil pump in. I've fitted a 26mm oil pump with external outlet. These made the studs too

short.

There was no way the pump was going to come back out with out allowing the case to seperate a bit, so luckily I was able to get two of them by locking

nuts and the other two with some vice grips. Luckily I had some cases lying around and was able to rob some 50mm studs and screw them in.

Just need to get some new pushrod tubes and I can start putting the pistons and barrels on.

BTW does anyone know the best way to clean carbon deposits from piston ring grooves. I probably should have used new pistons to go with the new

barrels but the old pistons measured up and look pretty good.

Use an old broken piston ring to scrape out the old carbon.

But careful, they can be sharp....unless you have a propper tool, that will work fine.

If your friendly with a workshop that has a tub of carbolene (spelling??) drop them in that for a day or two! Drop everthing except the case in! I

think you can buy 20l drums of it but dont know the $$. Would be real handy if you plan on doing more rebuilds ion the future.

Dont get it on your hands!

| Quote: |

thanks guys....We used to have stuff called carbosolve..same as carbolene i'm thinking. It was good stuff...trouble is I have neither or an old

piston ring...might have to go to a local engine builder.

Thanks TSV...I think I can comprehend what your saying...however there's a few guys on shoptalk forums and nobody has mentioned any issues like

that...not to say it wouldn't happen, but i'll keep it in mind when I strip it.

Also can you get power pulleys the same diameter as std. Want to ditch the pulley and run somthing thats looks the stuff i'm quite partial to these

although polished ally not hot pink!!!!

[ Edited on 26-7-2006 by Stanley ]

Well I've missed a couple of steps.

Barrels and pistons were on....yesterday....but today barrels came back off to fit .090 barrels spacers. This will put my CR at around 6.9:1 which

i'm led to believe will be good for a turbo and allow me to screw the boost up if the need arises. Chances are it will arise.

I fitted the barrel spaces and applied some blue max silicone on the sealing surfaces.

The other reason I pulled the barrels was to lap them into the heads. When I had the heads done the chamber volume was different between the 2 heads.

One was 48cc and the other was 51cc.

I had the head flycut to obtain the same chamber volume so I could use the same size barrel spacer.

Today I put the heads on making sure I remembered to put the air deflector tin on first.

Next weekend I'll do the rocker geometry. with the .090 barrel spacers I may need to make new pushrods. During the week i'll endevour to make an

adjustable pushrod.

Thanks so far should go to Craig from Crankshaft Engineering and Dave Butler for answering all my questions.

Nothing wrong with a bit of bling either. The crank pulley also doubles as a sausage slicer.

love the chick poster in the background

There's a couple...all volksie related of course.

should post some more......saw a man about a turbo today...going to build it to suit my application

Well the last piece of the jigsaw turned up today. Haven't posted any updates of late because up til now it was just a rebuilt VW engine.

I was originally getting a turbo of a john deere tractor that was supposed to be perfect for my application but it was to far gone.

Instead I've got a fully overhauled T02 (i think. has water cooling) off a nissan exa which has also had a carbon seal fitted for the draw thru

setup. Boost will start at around 2500rpm and is set currently at 7.5psi.

The beauty of this turbo I guess is that it has an internal waste gate where as the other one would have required an external wastegate. so i'll save

a few bucks.

All i need to do is orientate the housings and make the manifolds. i'll post some more pics once I start the manifolds.

[ Edited on 6-10-2006 by Stanley ]

[ Edited on 6-10-2006 by Stanley ]