Rod's Chop-Top Bus Tranny Upgrade

dangerous - January 20th, 2008 at 03:55 PM

Rod and Pete have been running his car for the last couple of years in All Motor class.

Mostly it has been with Pete driving and his 2332cc engine from the yellow car,

to a best of 12.1@about 110(I think).

'All Motor' Class minimum weight was 795.5kg at that time.

At the Warwick Event this year, and with Pete's yellow car not quite ready,

they slotted in a dunger 1915cc street engine that Rod had laying around.(7.5:1 and C35 cam).

Pete drove the pants off the car and squeezed out an 8.8, 1/8 mile time .

Anyhow, after having his first drive at the Jamboree re-run this past November,

Rod decided to upgrade the tranny for better shift quality.

This is where I come in.

Both Rod and Pete have always allowed me to tinker with their tranny's and over many years I have been able to share some little tricks that I have

tried on my own.

The tranny and its gearing were a little bit of a comprimise.

It had a 2lt casing and late 4 spider diff.

But other than those things,

it was basically a 1600 based bus box inside.

The only problem I found inside,

other than some minor wear,

was one of the spider gears had welded its self onto the shafts.

But I have decided to completely re-gear this tranny so that it more suits the All Motor type of racing that rod will most likely be doing in the near

future.

Also to be upgraded will be a LanD intermediate housing, to improve shift quality,

Special "Pablo" thrust arrangement,

and chrome-moly pinion nut.

nose cone thrust plate,

and an Albins steel side cover for the Vanagon cast diff.

dangerous - January 20th, 2008 at 04:04 PM

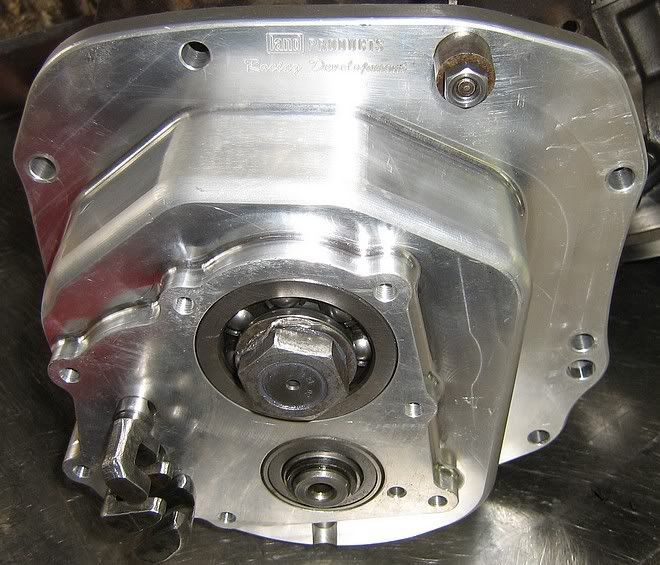

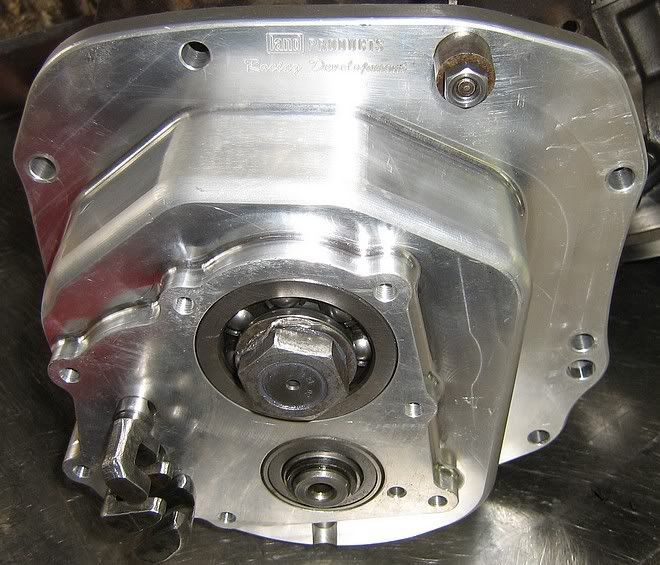

Chrome-moly pinion nut(mine for sample photo):

Nose cone thrust plate(mine for sample photo):

And Steel side cover from Albins:

dangerous - January 20th, 2008 at 04:40 PM

The spider gears that were damaged were replaced with some good used ones,

and all of them were bored in the lathe to get .002" more clearance to let more oil in.

Albins actually makes nice high strength versions for about $55 ea, but these only fail when the car does a one-wheel-burnout.

Once this was done, the diff could be reassembled, and a partial assembly done

to determine what shim was required to get a nice pattern on the 4.857 crownwheel and pinion.

The last ratio was 4.57 that I got from a 2lt box,

and I used a taper fit and weld to aapt an early 40hp shaft to, so that we could use it in a 1600 based box,

and some old gears I had laying around.

Other than wear, it held up well, but was a bit too tall for fast 60 foot times with Rod's 3.1 first gear.

Once the shim was set and I was happy with the end floats of 1st and second gear,

I made up a solid spacer for between 3rd and 4th gear.

For circlip ended pinion shafts I normally prefer to use the stock sprung spacer,

but because I was changing over to a solid thrust set-up in the nose cone,

this was needed.

I should also add that the stock magnesium housing is probably not really strong enough to do this job,

but you could easilly bore the housning right through,

and use a tapered bearing and thicker version of the steel nose cone plate pictured above.

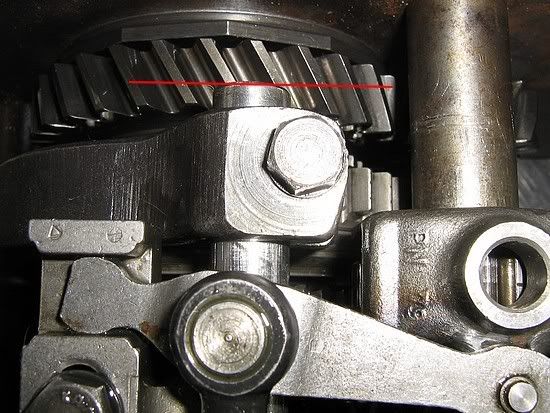

The 4th gear (now 1.04 ratio) was machined on its face so that it is nice and flat,

and also to locate an early beetle 1st gear thrust washer.

This will ride against a swingaxle diff thrust washer that is normally used to retain the side gears.

The 'snrub' is ground off to allow it to spin in the recess that I cut into the housing.

Must use the early version of this shim that is only about 3.2mm thick.

The more commom shim is about 4mm thick and would cause the recess to break thru into fresh air(=leak)

In the bottom f the recess goes some 36hp flyheel shims that are slightly ground down in their diameter to match the thick shim.

A 'poor mans posi' for the pinion.

Lucky I have a stash of NOS 36er shims.

Clearance was set at 3 thou.

dangerous - January 20th, 2008 at 04:54 PM

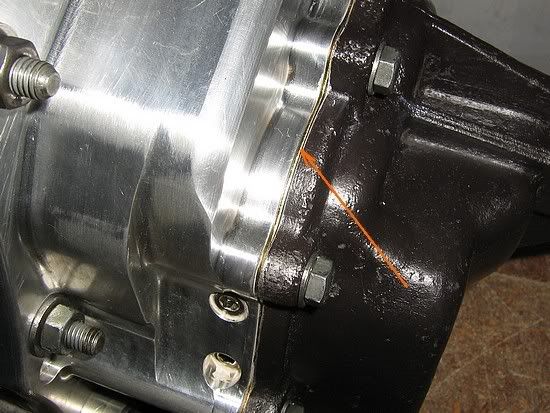

When converting to this style of intermediate housing,

there are a lot of beetle parts that need to be scrounged.

The best source for these parts in most cases is an early beetle(pre68 in this case).

Pete dug out an old core from behind the shed for these parts.

We use the following parts:

Early nose cone, studs and nuts.

(later one with seal NFG because the shortened hockey stick will not allow full engagementin 1st and 3rd)

Most of the time these will need re-bushing.

early bearings for mainshaft and pinion,

all the shift rods, forks, detent springs, balls and 'sausages'(no that is not rude).

Also the housing studs will come in handy since the mounting flanges on these aftermarket housings are about 12.8mm THINNER,

requiring shorter studs(or bolts)

and these spacers for the lower mount(if the original is welded into the car).

Stanley - January 20th, 2008 at 05:02 PM

Top work as usual Dude. You make it look easy.

Obviously if it was we would all be doing it.

cheers

westi - January 20th, 2008 at 06:47 PM

you have to love what you do ,and as we can all see you do.

keep up the great work.it always makes for good reading.

dangerous - January 20th, 2008 at 06:53 PM

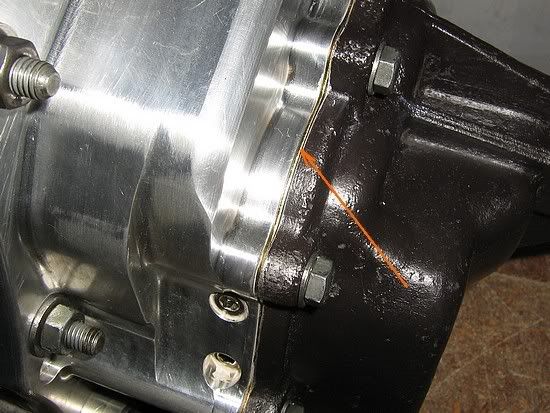

Another problem that arises is the reverse idler gear.

When using a late case,(2 lt one in this case), to get full engagement can be a problem

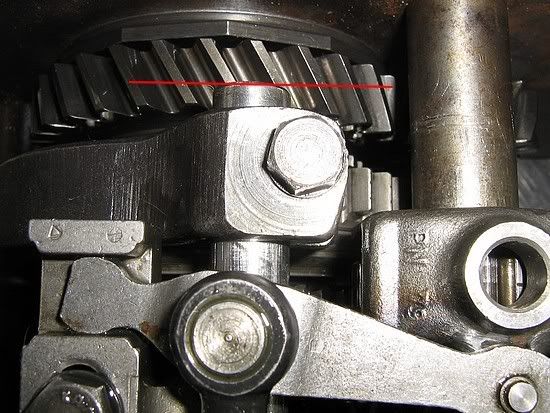

if you use the beetle brass fork and matching gear it bottoms out here:

I turned down the washer at the arrow,

and I counterbored a bus gear and used a steel fork from a 1600 tranny.

The fork required a modification to work with the (NOW) beetle reverse lever.

I reamed the nuts with an 8mm reamer from a flywheel/crank 8-doweling kit.

All set in the jig:

The advantage here,(and requirement), was that the taller 2nd gears(1.9286) rub on the beetle reverse,

but not the 1600 bus.

Also the bus fork is narrower in total width, allowing deeper engagement within the late gear case.

I could have used a late model bug or 1800 bus reverse, but then would have to change the mating gear,

and turn its OD down to clear the tall second gear.

This simple fork modification and counterbore machining allowed me to use Rods current reverse gear.

Erco also makes an aftermarket gear that wil be a bolt in no mater which reverse ratio you have(something like 21 different combinations!)

mactaylor - January 21st, 2008 at 06:54 PM

you should change your name to GEARBOXES GALORE! good stuff.

dangerous - January 21st, 2008 at 07:40 PM

The next step was to clearance inside the gear case.

The Beetle forks and shift rods are on the other side of the tranny,

so there are a few areas that need work with the die grinder.

On later Beetles and Buses, the 1/2 rod passes through the case for support.

This extra support is unneccesary with the better material of this intermediate housing.

Also early Beetles did not have this support either.

With a pre assembly of the gears stacks, the excess shaft length is removed.

Then 1/2 fork is also clearanced to reduce the amount required to be removed from the case.

Then a couple of hours with the die grinder, trial and error fitting:

This area is for the 1/2 rod and fork:

This area is clearance for the reverse gear arm pivot:

Another couple of views:

dangerous - January 21st, 2008 at 07:52 PM

At pre-assembly it was found that the 3/4 fork required some metal removal.

This is an early 4mm steel fork.

On my own tranny I used a 5mm fork, and it required much more room than this one.

After a thorough clean out of the chips,

I added studs rather than using the original bolts that are used for assembly of the housing on 2lt cases.

Everything is washed and ready for final assembly now.

Just waiting on a new pinion nut to arrive from the USA.

Final ratios are:

4.857 diff

3.1000 First,

1.9286 Second

1.4091 Third

1.040 Fourth

This should help to accellerate the car better at all points on the track,

and raise trap RPM by 700 on previous gearing.(about 7300 now)

mactaylor - January 22nd, 2008 at 03:38 PM

if the boys dont mind what are the engine spec's. not to much detail dont want to give to much away.l And what tyre are they running?

dangerous - January 22nd, 2008 at 06:53 PM

Tyre is 26" tall and 7 " across the tread.

Which engine combo?

VWFREAK - January 22nd, 2008 at 07:16 PM

Crazy stuff, makes for a great read.

Thanks Dave

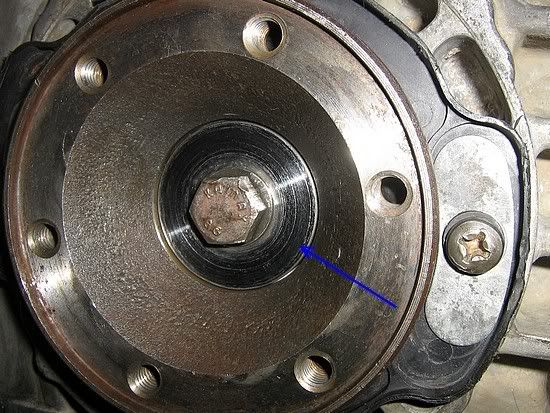

dangerous - February 8th, 2008 at 03:02 PM

Well,

the chrome Moly pinion nut arrived from America

so I have been able to continue with assembly.

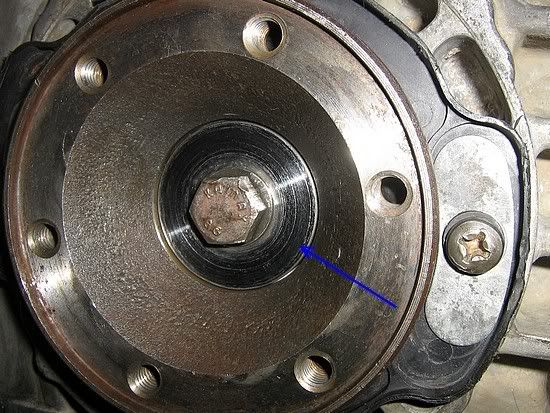

Here you can see the steel thrust plate:

I trimmed off the nose mount since it will not be needed,

The only thing remaining is to locate the dimple for the shift coupler.

It will be now about where the black mark is.

This is best done in the car and is fairly straight forward once a procedure is in place :

The end of the shaft is cut down from the standard beetle length,

because the bus crownwheel is larger and this moves the gear stack forward.

Bergs old kit used to come with a hockey stick pre-cut, but on mine the new dimple hole was not in correct index.

So by doing it in the car, I can get the index perfect with a simple vicegrip and electric drill operation.

The last mod was to make up some nice 4140 steel caps:

To give everyone an Idea on cost,

this particular transmission took me nearly 30 hours.

Being that it was very clean to start with, and required very few new parts,

you can imagine how much it would add up to if :

1. If it started off as a dirty old Kombi tranny,

2. If it needed new gears and bearings,

3. and shop rates that are out there these days.

(this is not a criticism of current labour rates, they are what they need to be, to stay in business).

11CAB - February 8th, 2008 at 04:31 PM

| Quote: |

Originally

posted by dangerous

Well,

the chrome Moly pinion nut arrived from America

so I have been able to continue with assembly.

|

We have the Chromoly Nut, and steel thrust plates in stock at work.

dangerous - February 9th, 2008 at 06:29 AM

Where is your work,

and how much?