Extra HP? I don't know but it has great torque from 1800 rpm to 4000 and more than enough to keep up on the freeways.

[size=1]Apologies if this topic has already been covered as I couldn’t seem to find a similar thread.[/size]

I know many of you know how to make big horse power.

Just looking to make maximum Hp out of a stock 1600 block whilst keeping it a daily driver.

At the moment I have an AS41 case, with dual 40mm kadrons, 009 distributer and a “modified” empi GT exhaust. Which I use in my 65 bug.

Question:

What would be the best setup in terms of bolt-on performance to get max Hp, with out any machining.

Eg: bigger heads, ratio rockers, slighty bigger pistons and barrels, etc.

With the view of eventually using these parts to build a bigger motor…. eventually..

Any advice or guidance will greatly appreciated.

Brett

Have a read here

http://www.aircooled.net/gnrlsite/resource/articles/mods.htm

I would consider a set of 044 heads and ratio rockers as a bolt on but as you are looking to build up bigger later...., if it was me stick to what you have and save for another engine, build bigger from the base of a stroker crank, better cam, etc instead of throwing cash at something that you need as a daily commute to work. The reason is that if you get better heads then you need to upgrade the cam, and while you have the case apart then you would replace the main bearings which means the crank may need grinding, so get a stroker and be done with it, then upgrade to better rods...... and you can see where this is heading. Drive what you have and save for the bigger engine, do it once and do it right.

Hi 66brm, I am just wondering how much extra HP would you get out 1600 with stock stroke engine??? Thanks Dean

I run a 1600 with a counterweighted crank, w110 cam, 1.25 ratio rockers, dual 40idf's, A1 sidewinder, 044's with 40x35.5 valves and static

compression at 8.6:1, lightened flywheel and kennedy stg 1 pressure plate. It's completely different to a stock 1600. I built mine from the ground up

which is what I recommend you do, if I had the opportunity to do it over I would have gone for a 74mm stroke and probably 90.5 pistons and cylinders

with the same heads cam etc, but as a first time performance engine build up I've been really happy with the result. I drive it on a daily basis, and

have driven it across Aust a couple of times and also up through the centre averaging 120kph. It has only let me down once in the 10yrs since I built

it, a faulty distributor button

Extra HP? I don't know but it has great torque from 1800 rpm to 4000 and more than enough to keep up on the freeways.

| Quote: |

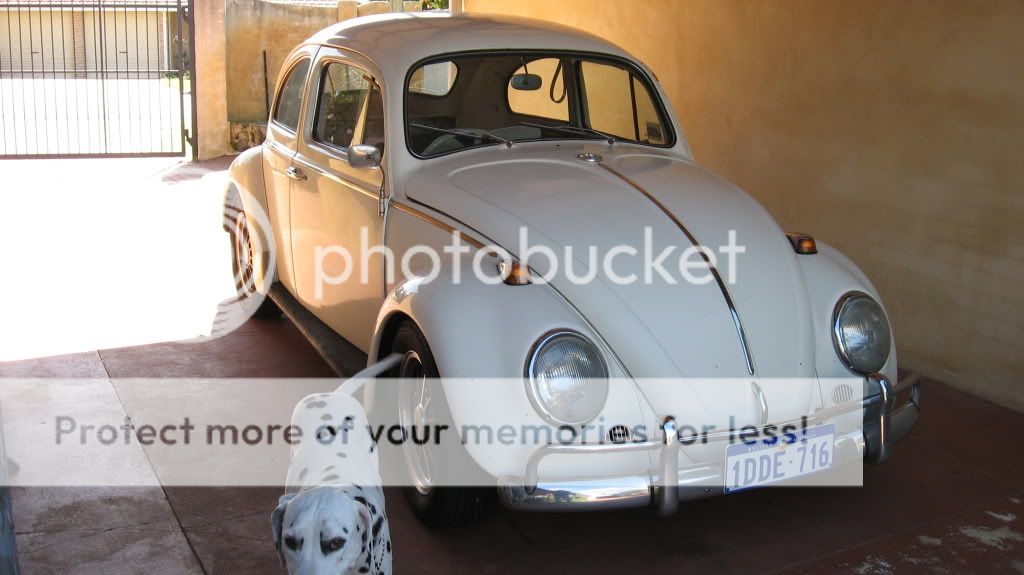

This is my 66, I don't have a pic of the engine but will get a couple tonight if I get time

Stock transmission?

And whats the set up with a lightened and balanced flywheel? Do you need a heavier then stock bottom pully or lighter than stock pully?

At the moment I've got heavier than stock pulley with a stock 1600 flywheel.

Yeah standard 1300 trans, top gear is probably a bit short for long drives but around town its through the revs nice. The flywheel I had lightened, quite a bit and then had it balanced as part of the rotating assembly, it just increases the engines response to throttle inputs. Bottom pulleys, well you can do either, the one I have fitted was also balanced to ensure smooth running at higher rpm.

Was there a big change in torque? or did it pull just as hard of the line.

Nice bug & engine by the way

I've never run the engine with a stock weight flywheel, but others of similar spec I've driven and worked on don't rev as freely, if thats the right word, it certainly picks up the revs faster and I've found easier to accelerate up decent inclines. Its a bit dirty at the moment, needs a good clean, it'll get it when I clean out a blocked idle jet this weekend

Hi nice photos and like that engine and thinking bulding one myself with single webber here in my 1974 T1 at moment its 1300 and front end is lowered and converted do diskbrakes cheers

When you do need to machine the case: what needs it and where (aside from boring out the case for bigger pistons) - what will cost the money maching wise?

great topic i have a standard 1600 twin port and would like to do a few mods to increase HP

just bolt on.....twin carbies and a good exhaust give a good return on a stock 1600

My 1600 at the moment has most of the bolt on stuff inc L&B flywheel.

And I'm quite happy with it, althought I can't really recomend the gt ehaust I got it to chop

it up and give it some attitude  It's good fun to drive now.

It's good fun to drive now.

Intersted to know how much it would cost to port, polish and possibly flycut my stock 040 heads?

anyone do performance vw heads near moorabbin VIC?

If your set on building a peppy 1600 before a big motor just rebuild what you have. Port the heads yourself (theres a good article on cal-look.com

about this), use a stock crank and keep the revs sane. Put in a mild camshaft like an engle 100 and twin carbs and extractors.

After you have learned how to assemble a little motor with a few tricks in it hopefully you'll feel confident enough to spend some $$$ on bigger

engine.

http://www.amazon.com/Beetle-Performance-Handbook-Step-Step/dp/0760304696/ref...

The above book is a good guide for getting started, civers everything from mild to wild. A little outdated but still mostly relevant.

expect in the region of $700 - $900 for the head work, i've had a quote on my single port heads by a formula vee guy for about that much.

Buy some new heads like the CB Lospanchito, they are a stock casting so have excellent cooling but bigger valves and a cnc port job that can flow up to 180 hp, 'out of the box'. Cost under $1000 and are brand new, including valves and dual springs. With your stock bottom end (?) fit 1.25 rockers (if a stock cam), 40 IDA's, merged 1 1/2" exhaust and your L&B flywheel and it'll be a winner.

| Quote: |

...

...

single springs.

Yes having 1.4's will affect your cam choice, most cam grinders will specify what ratio rockers will work best for their cam profiles, an engle w110

for example is suited to stock 1.1's or 1.25's. Fitted with 1.4's you will see over 0.5" lift and be in danger of touching the piston crown with

the valve head, coupled with accelerated cam, lifter, rocker, spring, valve and valve guide wear.

You say that you had the rear main seal replaced recently on your engine, was it an Elring one you used and was it seated correctly? Also is the drain

from the rear main to the sump clear of sealants and other stuff, this will cause oil to push past the seal. When you replace the seal check your

thrust bearing then also, remove the shim stack and have a mate push and pull on the pulley, the rear bearing if flogged in the case will float in and

out with the crank.