Insulated connectors or Non Insulated

Camo - January 25th, 2011 at 12:29 PM

I am looking at making my own wiring harness and was wondering if I should buy the insulated connectors or the non insulated connectors like factory.

I will be putting heat shrink tube over either type no matter what.

I notice that the pliers required for insulated or non insulated are different and I have a few of the cheap insulated type pliers already, but dont

mind buying the other style.

Which is the better finish/connector.

Thanks, Kev.

barls - January 25th, 2011 at 02:27 PM

depends on which crimper you use.

the insulated ones with the proper ratcheting crimper are excellent. they are what we use at work and also what i have on my car.

ian.mezz - January 25th, 2011 at 02:34 PM

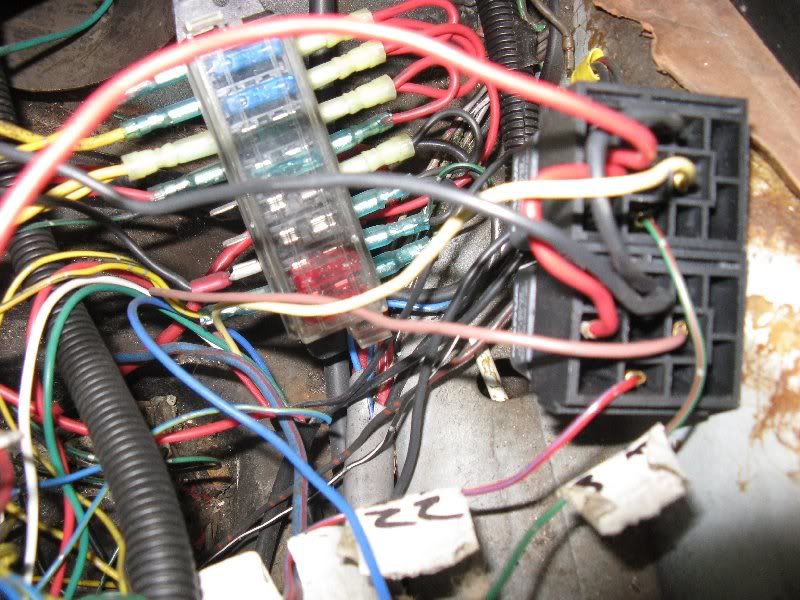

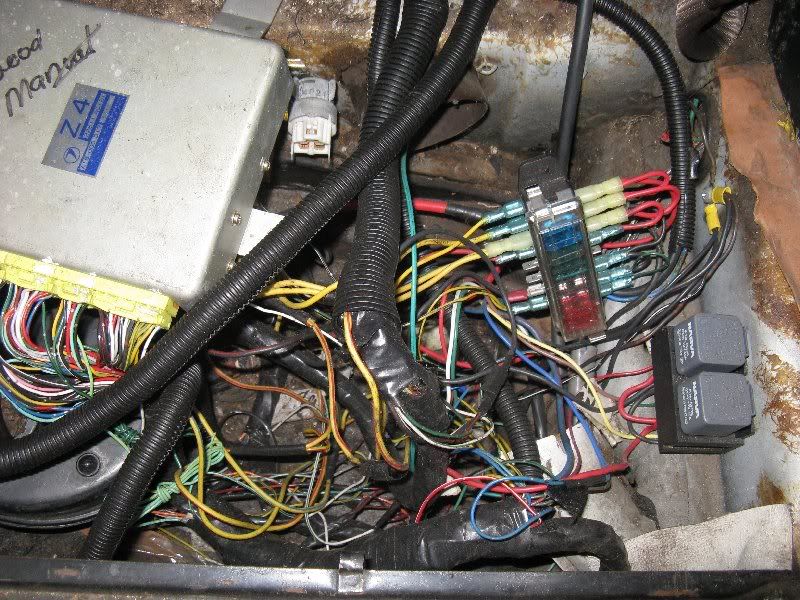

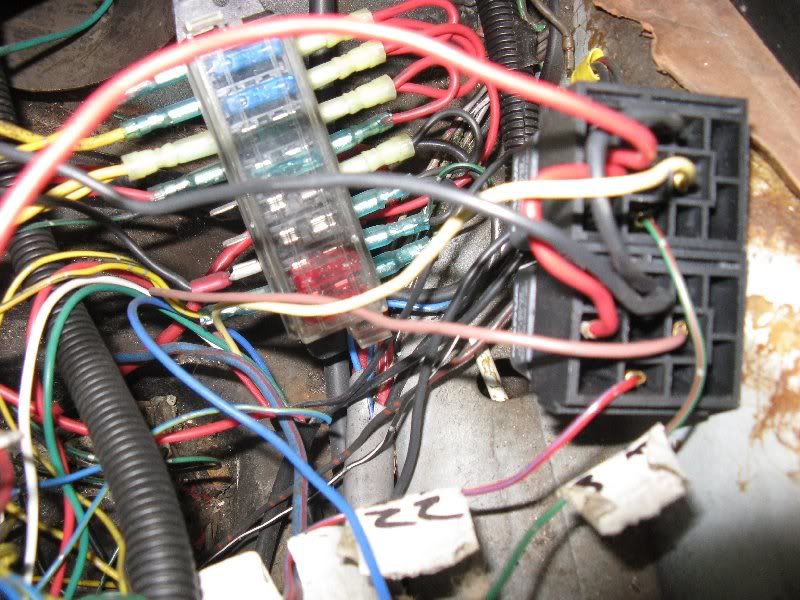

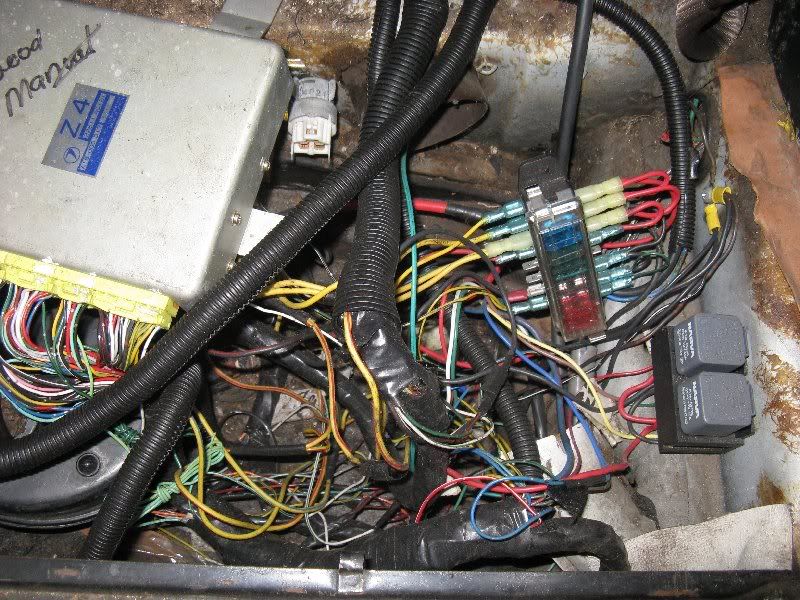

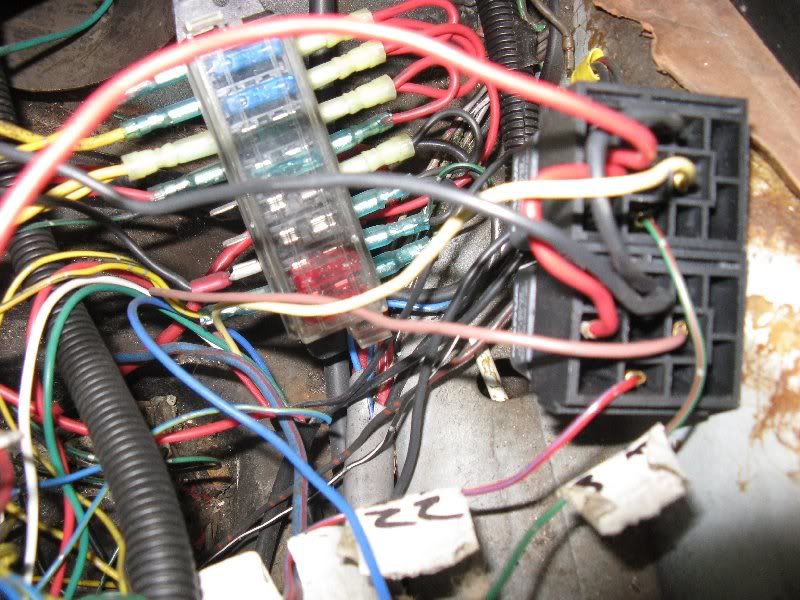

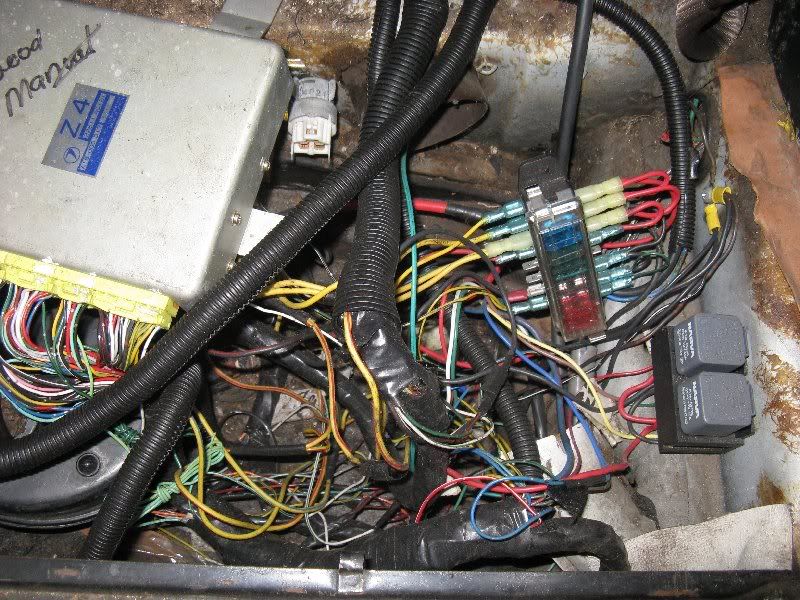

As long as the wires look like a birds nest when you finish.

here some that I have done.

here some that I have done.

give me a call if you need a hand.

pliers http://www.narva.com.au/products/browse/tools

http://www.narva.com.au/products/browse/tools

Camo - January 25th, 2011 at 02:43 PM

Ian, that looks like factory wiring so when can you come down and fix mine

Barls, I know you need the right crimper for the particular terminal. Just the difference in the way they crimp - the cheap insulated pliers I have

basically just flatten the circle shape of terminal out but I thought the other type pushed down the centre of the circle and may be a stronger or

better style of crimp.

Kev

barls - January 25th, 2011 at 02:50 PM

i cant comment on the non insulated as its been a bloody long time since i used them. i know that all mil spec gear is ether high precision soldered

or insulated crimped using one of these

http://www.narva.com.au/products/detail/959/noheaders/1/?KeepThis=true&TB...

i wouldnt use anything else. the cheap crimpers are just that they destroy the terminal when they crimp.

btw they are cheaper at bunnings, thats where i bought mine.

zocstar - January 25th, 2011 at 06:05 PM

I'd go non insulated. I think it will look neater.

As far a crimping and security, if you use the right and quality tools they both will be fine.

One advantage on the non insulated is that you can also solder them for a "never have a problem finish".

Trust me I'm an auto electrician

Paulc1964au - January 25th, 2011 at 06:18 PM

Kev,

I would go with insulated lugs it reduces the risk of short circuits with adjacent terminals. In our industry railway signalling we wouldn't dream of

using uninsulated crimp lugs however it is imperative you use the correct correct crimping tool

68AutoBug - January 25th, 2011 at 06:53 PM

| Quote: |

Originally

posted by Camo

I am looking at making my own wiring harness and was wondering if I should buy the insulated connectors or the non insulated connectors like factory.

I will be putting heat shrink tube over either type no matter what.

I notice that the pliers required for insulated or non insulated are different and I have a few of the cheap insulated type pliers already, but dont

mind buying the other style.

Which is the better finish/connector.

Thanks, Kev.

|

Hi Kev

I have used the non insulated terminals and soldered the wires to the terminals and covered with heatshrink...

I did My whole car... with lots of extras...

and there are good crimp pliers at Dick Smiths ..

they do an excellent job...

You can buy really expensive ones that have a ratchet in them

they would be best....

NOW.... after soldering maybe 50 or more copper terminals and using heatshink.... I have found the terminals I used...

male-female.... do not click together... just push together and come apart very easily...

so, I have started again.....

I'm been using plastic covered connectors and soldering the wires first.... and crimping....

and when the male/females are clicked together..

they stay together... lol

and I have replaced My VW fusebox with push in fuses..

cheers Kev

Lee in 43C today.....

Camo - January 25th, 2011 at 09:07 PM

Thanks for the replies.

Paul, as I mentioned I am still going to use shrink tube over the connectors to avoid any accident shorts.

Zocstar, the soldering was also what I was thinking about doing with the non insulated for extra assurance.

Lee, what was wrong with the terminals you used that they come apart - were they cheap ones?

Cheers, Kev

helbus - January 25th, 2011 at 09:24 PM

Have a look at the catalogue on this website. I go there to buy all my non insulated terminals, and put single blocks or more on them.

Crimped and soldered. OEM style terminals only.

http://jaydeeautocables.com.au/

68AutoBug - January 26th, 2011 at 12:19 AM

| Quote: |

Originally

posted by Camo

Thanks for the replies.

Paul, as I mentioned I am still going to use shrink tube over the connectors to avoid any accident shorts.

Zocstar, the soldering was also what I was thinking about doing with the non insulated for extra assurance.

Lee, what was wrong with the terminals you used that they come apart - were they cheap ones?

Cheers, Kev

|

Hi Kev,

I bought them all from Dick Smiths and they weren't cheap..

and now it seems they were made for slipping into plastic plugs and sockets... and they locked into the socket...

but not into each other.....

they were not made for crimping either..

the wires were soldered onto them with two bits to push over the cable...

actually I had a big packet of utilux ones too....

I'm now using narva plastic covered crimp terminals...

In old VWs I like the white connector strips where You can put two or more wires into the strip and tighten the two grub screws....

these come in about strips of 10 ??

and in two sizes - small and large... maybe another size??

the larger ones are better to push the soldered wire ends into

I will have to take some pics for you Kev..

depends on what You like...

under My bonnet at the moment are about 50 +wires, individual fuses and circuit breakers as I haven't wired up My new fusebox yet .... as it is over

the top of the hole where the original fusebox was... so if i blow a fuse I would need to take the back of the dash cover off....

I have seen where the fusebox is mounted on the dash cover

which was made from wood or metal and covered with vinyl.

looks very impressive and You cannot see any wires... lol...

only the fusebox.... I have a new fibreglass dash cover...

I ran a seperate wire for every item Kev... lol plus spares...

I used 7 core trailer wire - one of them inside the tunnel...

I ran two 6mm wires from the alternator to the battery and three to the dash... so, no low voltages there...

but heaps of wires.... lol

its Ok if You label each wire.... lol...

LEE

clinker42 - January 26th, 2011 at 08:08 AM

Dont crimp

Use un insulated terminals and heat shrink. Lee, you must be doing something wrong, I solder about 300 - 400 terminals a week and never have an

issue. You only crimp if its a last resort, a crimp connection offers more resistance and doesnt have the longetivity.

here some that I have done.

here some that I have done.

here some that I have done.

here some that I have done.