can not find anything on the solenoid? but here is the adjustment page

nbturbo may have some later info

Grahame

Mated to my ea81 on Tweety the trike, I've known for some time now that there are two exterior adjustments on this model trans that I think is out of

a type 3.. Its full auto 3 speed.

Oil has been changed and filter cleaned and pan gasket changed. I also find that the trans works better with the fluid a little above full. If at

full or under then it can lose gear on slow small hills eg my driveway.

The solonoid has an adjustment inside it using a small spade screwdriver. I can adjust this to adjust the kickdown points. Too much unscrewing and it

will hunt for gears particularly 50kph between 2nd and top. Th'at annoying because it is the best point of kickdown operation to utilise the power

band on the Subie Brumby donk or the previous VW 1916.

I am aware through other web sites that the other adjustment, on top of the trans works in unison to the solonoid adjustment but I cant find out

how.

I've approached several auto trans services and not one is willing to take the job on of adjusting the trans.

A Haymes manual states that the top adjustment should be adjusted to 7lbs but this is a little vague.

Can anyone shead some light onto how these two adjustments work togather and what the top adjustement actually is ? (my suspicions is band

adjustment)

Need an old school auto trans expert!

See 20 readers and no replies.

That's typical of questions about the VW auto trans...no one knows anything!!!

Bloody manual junkies lol

When I can get some spare time I will get all the details you need and post them. I have a Type 3 auto in my Oval Beetle and have a VW workshop manual which has a comprehensive section on the 003.

I have an old Volkswagenwerk Service manual on the 1600 Automatic

can not find anything on the solenoid? but here is the adjustment page

nbturbo may have some later info

Grahame

Have pm'd you nbturbo.

thanks also Grahame.

One day I'll be an expert auto trans adjuster and give advice to others.

some times by doing some over due adjustments on a old trans can cause other wear to show up and cause something else to play up .

yeh. If it aint broke? my intention is to stop the gear hunting and I think it is due to the band adjustment a little out. I make sure the oil is

changed often.

slowly gently eh. just a little bit!

the trans is nealry as old as me!

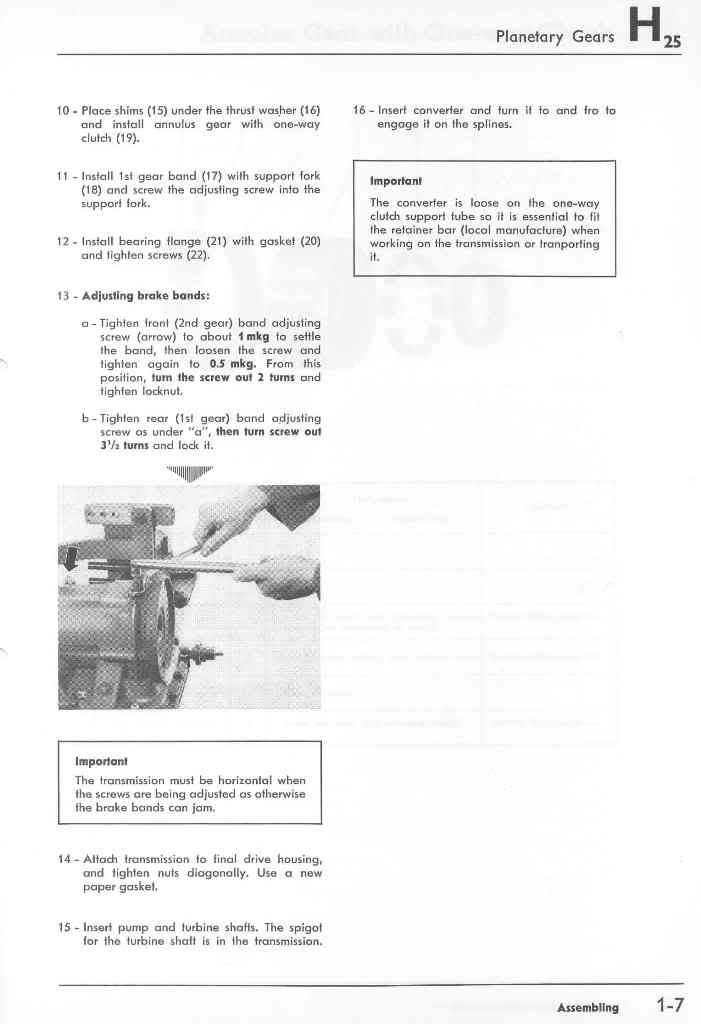

Hi Tony, Are you talking about up shift or down shift?? There is no need to adjust the 2nd gear band as the piston and shaft has enough movement to

clamp the band even with out any friction material

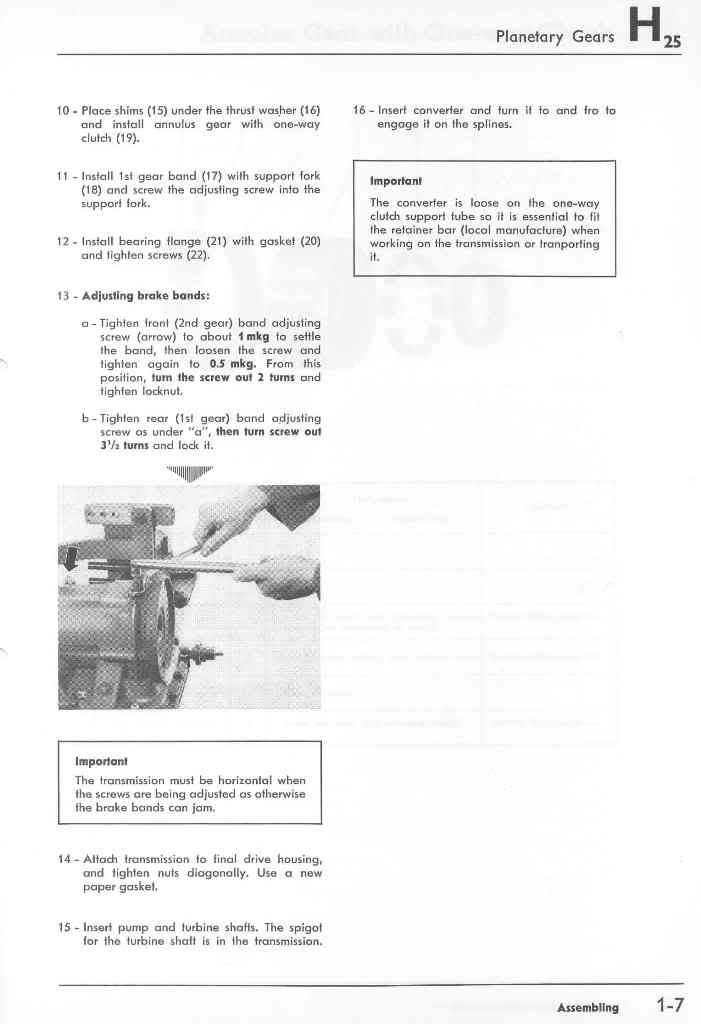

on the band. the only time this needs adjusting on vws is on a rebuild. The 2nd band adjuster is at the "arrow" not the one they are seting which

is the 1st reverse band.

It sounds like the dipstick /filler tube isnt in the correct position. showing incorect fluid level ?

When setting the primary throttle you should have a guage to show the pressure difference same when setting the main pressure and main pressure

regulating valves. These all can be changed in the valve body to create different shift points or to achive more holding pressure to the clutches to

take the power of a larger engine.

These perssures all work together.

I do this in the lathe

Is your electric kickdown solenoid working??? The primary vacume pressure soenoid changes up and down shtfts in conjunction with the govenor (road

speed).

If its hunting i would only adjust the vacume unit untill it changes smoothly. This may change to soon for the subi engine. It will not hurt it to

change it manually.

hi 20bkombi and thanks

I dotn beleive my electrical solonoid is working. connected 12V to it and I dont hear anything.

Is it internal? seems that way. The vacuum adjustment I can adjust up to get correct changing points but too far and it hunts between 2nd and third

forcing me to screw it back in. So will the electrical solonoid, if not operational compound this or cause this?

The changes down are fine. The kickdown operation works.

As far as brake band adjustment is concerned I dont have enough knowledge to tackle that.

The electric solenoid should be switched by the throttle when at 'Wide open position' to make the auto kick down.

This does not make it serge between 2nd and 3rd. Lots of things could cause this, to high throttle pressure, dirty governor or valve body. I've seen

the transfer plate wear out where the ball bearings move across the holes. Could also be old rubber piston seals gone hard for 2nd band, bypassing

pressure.

You can take the v/b out, take it apart then clean and assess for wear, (just be carful not to lose the ball bearings) from here you can test the kick

down solenoid.

Hope this helps

Aaron

Thanks Aaron. I mounted the kickdown switch to the throttle to turn on at full throttle so thats ok. Today I adjusted the vacuumsolonoid again and

got it to kick down spot on and it doesnt hunt for gears at all now so I think this adjustment wasnt right where it should have been.

hoping i can one day buy a spare auto box/transaxle for a total rebuild. so if you hear of one???

as a matter of interest I had a dyno a few months back with the ea81/weber 32/36. had 75hp at the fly and 60 at the wheels. not bad. but the auto

zaps a lot of horses from it. so a small supercharger is a possibility in the near future.