CNC Machining

Birdman - July 5th, 2012 at 06:36 PM

Does anyone have any contacts for CNC machining?

I have a mill and a lathe but need some complex parts made.

I think it's a 3 axis job.

I can probably supply the Billet and resolved CAD file but i expect most shops will tell me to go jump or charge the earth.

All help, advice and ideas welcome.

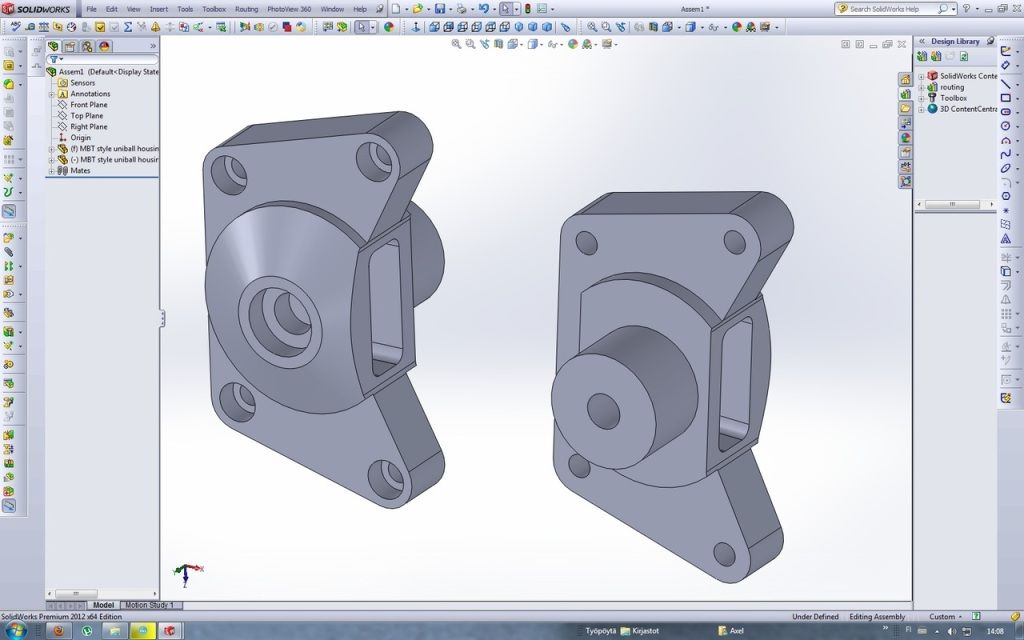

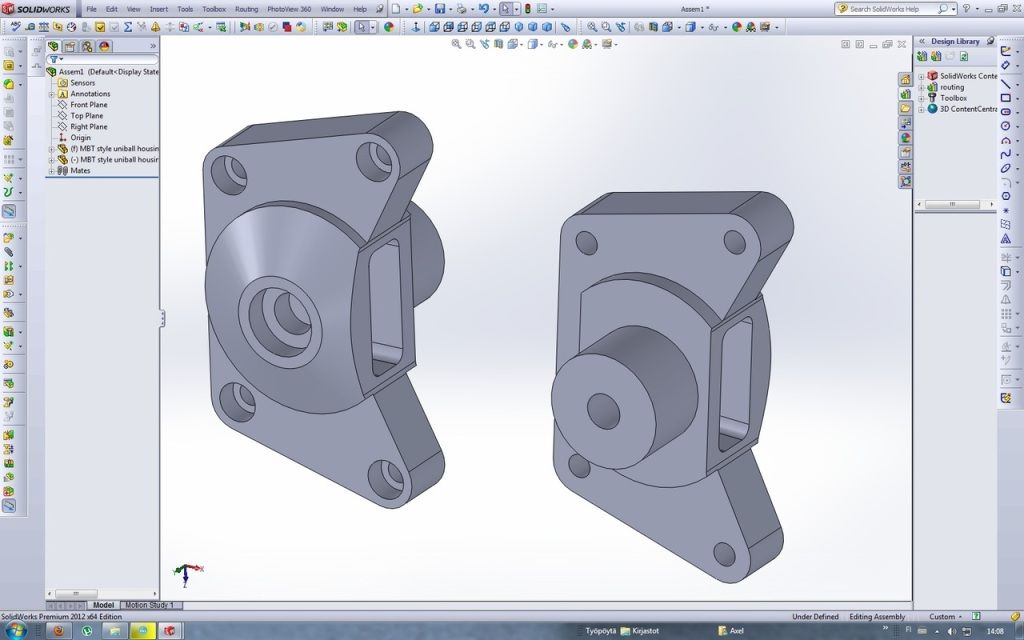

The project:

barls - July 5th, 2012 at 06:57 PM

try phbillet on here

pod - July 5th, 2012 at 07:15 PM

You would need a cnc machining centre,and Peter is a toolmaker but rarely gets on here ,I only have a cnc lathe at work ,and only know basic

programming ,so yes you would need an expert or the cad program that can devise the program to machine this,best of luck getting it done cheap

Sides - July 5th, 2012 at 07:23 PM

Mmmm... SolidWorks Premium 2012 x64... that woulda cost a pretty penny !!!

(noticed it since I'm still on 2005 ya see)

Pretty sure had a "generate CNC routine" function now, it might help you figure out what kinda machine needed perhaps ???

UPDATE: Google is my friend... look under the Tools menu at CAMWorksXpress

Tim Andrews - July 5th, 2012 at 07:47 PM

I can do no probs at all.

As for charging the earth, the price will be based on hours required to program machine, set-up machine and running of machine plus material if not

supplied.

If there are only the 2 off, then yes you could be up for a bit of coin.

As i tell all of my customers, the more you do, the cheaper it gets.

Where are you located? I'm more than happy to look at it for you.

Birdman - July 5th, 2012 at 08:04 PM

Thanks for the replies guys.

The guy who designed these can supply the files and also all the solidworks stuff. He is a whizz at both.

Tim, PM sent.

vlad01 - July 5th, 2012 at 09:50 PM

about 160 per hrs plus setup time, which is the expensive part

good luck!

bajachris88 - July 6th, 2012 at 08:46 AM

With that 4 stud pattern/shape anyone would guess it was some new setup for the springplate/rear torsion bar fixing

BiX - July 6th, 2012 at 12:53 PM

did I see a thread about somebody selling a kit to do the same? depending on price, could end up cheaper.

vlad01 - July 6th, 2012 at 01:19 PM

| Quote: |

Originally

posted by bajachris88

With that 4 stud pattern/shape anyone would guess it was some new setup for the springplate/rear torsion bar fixing

|

i thought it was for the gear box, jk

cnfabo - July 6th, 2012 at 08:31 PM

there is a guy on one of the other overseas vw forums who has made these for a good price..i saw them the other week ,i tried searching it on

shoptalk but couldn't find it...

Birdman - July 7th, 2012 at 07:52 PM

yeah yeah bajachris88, no mystery what im making there mate.

and yes, that guy on the other forums drew them up for me with some alterations to suit australia. I wanted a 1 peice design and i wanted all the

stresses transferred into the torsion housing with the springplate cover bolts just locating it to the tb housing. I spoke to a certain german tuning

company about making them when i was over there but due to potential manafacturing tolerances from vw they couldn't gaurantee they would fit exactly

so wouldn't make them for me. They slug will be a tight interferience fit into the torsion tube. Hopefully this will satisfy the nsw rta and

engineers. Just waiting for my cousin to get his finger out and help me source some billet and cromo. I am buying that guys spring plates though as i

think they are spot on. search germanlook if interested.

vwo60 - July 8th, 2012 at 10:19 AM

I do not under stand how you are going to get that tight fit in the torsion bar housing, the casting is friction welded to the tube along and with the

excess weld material inside the tube will stop you fitting it easily, you would have to individually fit each piece to the tube using a die grinder,

the four eight mm bolts that hold the cap on are not sufficient to carry the load even if you locate it in the tube, the longer the spigot the less

load the bolts will have to carry, have you thought about using a through bolt across the car to help hold the mounts in place .

1303Steve - July 8th, 2012 at 02:10 PM

Hi

Birdman and I were talking about this the other day.

I suggested welding a decent steel slug into the torsion bar housing and then making a fixture that bolts to the four bolt holes and then accurately

drill the centre hole.

Steve

psimitar - July 8th, 2012 at 11:42 PM

| Quote: |

Originally

posted by vlad01

about 160 per hrs plus setup time, which is the expensive part

good luck!

|

Bahahahaha. That's some joke. CNC programming is dead easy as did that at college b4 the software that could turn a CAd drawing into a CNC file.

Set up time. Hmmm, clamp in the vice and zero the machine. Wow, all of ten minutes whilst drinking a cup of tea :P

Birdman - July 8th, 2012 at 11:49 PM

Thanks for the reality check Mike, I dont tend to listed to vlad much.

Are you talking to me again vw060? Yes each piece will be individually fitted to each tb housing.

psimitar - July 9th, 2012 at 12:48 AM

| Quote: |

Originally

posted by Birdman

Thanks for the reality check Mike, I dont tend to listed to vlad much.

Are you talking to me again vw060? Yes each piece will be individually fitted to each tb housing.

|

No worries  I'll admit that CNC machines cost a whole bunch but still

don't think it warrants the cost per hour

I'll admit that CNC machines cost a whole bunch but still

don't think it warrants the cost per hour

HappyDaze - July 9th, 2012 at 08:42 AM

Finance on the machine alone could be somewhere between $50 and $80 per hour.

vwo60 - July 9th, 2012 at 09:20 AM

People want to get into the real world and run a engineering bussiness for themself,the cost of the CNC is justified at the rate quoted, as for the

operator he has to be paid along with all the other expenses of employing a skilled person, if it is that easy and cheap every man and his dog would

be doing it. Birdman, as suggested you could fit a through bolt across the car to assist the locating of the plates.

Birdman - July 9th, 2012 at 09:49 AM

| Quote: |

Originally

posted by vwo60

People want to get into the real world and run a engineering bussiness for themself,the cost of the CNC is justified at the rate quoted, as for the

operator he has to be paid along with all the other expenses of employing a skilled person, if it is that easy and cheap every man and his dog would

be doing it. Birdman, as suggested you could fit a through bolt across the car to assist the locating of the plates.

|

The throughbolt is an interesting idea.

The machinist i live with wants a crack at making them on his mill and lathe which would be nice.

psimitar - July 9th, 2012 at 11:02 AM

| Quote: |

Originally

posted by vwo60

People want to get into the real world and run a engineering bussiness for themself,the cost of the CNC is justified at the rate quoted, as for the

operator he has to be paid along with all the other expenses of employing a skilled person, if it is that easy and cheap every man and his dog would

be doing it. Birdman, as suggested you could fit a through bolt across the car to assist the locating of the plates.

|

Mate the cost of anything in this country is ridiculous. YOu can pick up a good quality CNC mill for 17k in Europe so 34k for a mill and lathe ain't

that bad. If the cost is that high for a machine in Oz then I feel sorry for the people having a a CNC business. And I know these prices are fairly

relevant as my dad only retired from the job a few years ago

Anyhow, Birdman. A skilled machinist could make those parts of a mill but compared to CNC it'll take them a while setting the angles etc.

Birdman - July 9th, 2012 at 01:01 PM

Glad to hear you think it can be done Mike. My house mate is retired and loves nothing better than sitting in the shed making stuff.

Special Air Service - July 9th, 2012 at 10:44 PM

Ron, will he work for beer?

Birdman - July 10th, 2012 at 10:35 PM

Maybe?

What do you need made?

I'll admit that CNC machines cost a whole bunch but still

don't think it warrants the cost per hour

I'll admit that CNC machines cost a whole bunch but still

don't think it warrants the cost per hour