The last Hellbug

hellbugged - May 2nd, 2005 at 02:25 PM

getting ready to assemble my engine, thought some of you would like to follow the process.gonna post some parts pics first and shall be adding text

over the coming week .if anyone wants more detailed or comparison pics i'd be happy to do that too.yes i do like berg stuff but i am not an employee

of their's,(sponsor maybe), nor am i trying to advertise gene berg,(i highly reccomend their service and products though) it just their products i am

using. here goes...

nos as21 (1991) bored for 90.5 by bergs (smoothest finish i've seen) will be tapping for full flow oil, welding extended oil pick up, spot facing for

15mm wrench size head stud nuts and washers. will post pics of these processes soon

pictured is head stud kit ----- fuel pump block off------t3 block off, to be tapped for temp sender------

case assembly/conversion kit-----c.b cool tin-----dip stick temp sender-----pressure relief kit---- washingto anti shocker (attaches behind clutch arm

to slow closing during drag style starts reducing stress to components its like a small shockie and very adjustable sorry nos no longer available, so

ner!--- main bearings-----and adapter for pressure sender & oil light:duh

hellbugged - May 2nd, 2005 at 02:27 PM

heres the 8 dowel 69mm berg crank,visit their web site for the processes that go into producing one of these---- berg selected 90.5 pots (1991

models)balanced & hand honed---total seal second ring set, converted from the original rings that came with the P & B set------ balanced, mag fluxed &

shot peened rods & bearing set----wrist pin keepers vs wire clips----nos brass timing gear----new factory dowel pins for bearings (missed previous

pic)

[ Edited on 26-11-05 by dumone ]

hellbugged - May 2nd, 2005 at 02:31 PM

ahh clutches; green one is 2500 kep -cable breaking , tube bending, leg working muthaf. (used) note bars to aid rigidity---new 1700 pound berg

selected match balanced to berg lightened flywheel----old flywheel at back----L to R-- abused dual friction rigid disc by bergs so good had to get

another (middle) ordered from bergs this time last week!!!----(right) is standard face springless german made.-----washington anti shocker---- steel

gland nut and oversize washer, have cro mol long one to use currently on car tho. some of these spares will be up for sale at projects end.

[ Edited on 26-11-05 by dumone ]

hellbugged - May 2nd, 2005 at 02:41 PM

sometimes you just end up with more than you need (selling spares later)why three cams? turbo grind eagle, berg 300 (no ratio rockers) berg309/

V26engle (for ratio rockers) at this point i should state that most of this stuff was bought as a 1776 kit, a turbo kit was also purchased, had spares

from deceased 2180, and also bought some more stuff just because i wanted to do things other than what came with the kit. gears (top to bottom) magnum

straight cut alloy on steel (still attached to remainder of 310 cam)--- berg/magnum steel on steel straight cut with bolts and three sets of washers

for adjustable timing----berg nos helical gear----eagle adjustable timing helical gear and washers---also pictured timing gear kit (oil

slinger,spacer, timing gear,woodruff keys, new dizzy drive shaft, spring and shims, brass dizzy drive) ----spare brass gear and timing washers, so

when i sell spares it will be complete cam gear set up---new pressure plate bolts make guest appearence cos they missed flywheel pics, isnt it sad

when you loose the plot so bad that you by these justified by telling yourself they will fill a hole in the box your importing.

while i'm on the subject i have obviously been getting a bit from os and found it cheap and easy, last week $130au = $100us didn't cop any import

duties either, watch out for freight tho:duh

[ Edited on 26-11-05 by dumone ]

hellbugged - May 2nd, 2005 at 02:51 PM

o.k new cro mol pushrods , one end not assembled---used ones---lifters top to bottom, black standards---berg/mahle modified, small cut between oil

rings to aid constant pressure and machined under head for case lifter bore clearence---berg selected standard mahle---dual thrust copper faced cam

bearings---c.b race pushrod tubes & seals, tappered end for pushrod clearence with ratio rockers

[ Edited on 26-11-05 by dumone ]

hellbugged - May 2nd, 2005 at 02:51 PM

heads; berg installed seats 40mm & 37.5, new guides installed, BUT, the ports have not been matched to new seats,guide bosses will need cutting down

for inner dual spring, may also semi hemi, intend on posting pics of these tricks later.

pictured L-R----array of cylinder spacers/shims for compresion to be set---nos manley stainless valves---dual springs set--hardened keepers, gapped

not to touch--cro mol retainers---1.4 ratio rockers

---lash caps--spring shim kit, that'll be fun!--spare guides---solid rocker shaft kit

--swivel feet adjusters and rocker geometry shim kit---heavy duty rocker studs:kiss

[ Edited on 26-11-05 by dumone ]

hellbugged - May 2nd, 2005 at 02:54 PM

oiling;big sump over 6000rpm-- lil one for under 6k---oil thermostats, needed cb one to run braided lines (fittings)--oberg cleanable filter with

tattle tale that tells when cleaning is necessary---26mm tapped and plugged pumps one has o'ring at cam end, so its the one for me---pressure relief

cover for cold starting---sump pickup tube & magnet---mounting kit---teflon hoses, read recently that gene ran a set of these lines for over 20

years,hence the "lifetime" tag

[ Edited on 26-11-05 by dumone ]

hellbugged - May 2nd, 2005 at 02:55 PM

6 1/4 pound equilizer pulley, these are machined from steel bar--oil pump seal nuts and copper coated exhaust nut sets missed their fashion

shoot--super strength longer pulley bolt with large & small beville washers, tourque to 100 pounds! but check your crank quality first.

[ Edited on 26-11-05 by dumone ]

hellbugged - May 2nd, 2005 at 02:56 PM

induction; dual 48mm dellortos with berg ball type fuel inlet valves installed (used) these reach full flow with minimum float travel, manifolds will

need match porting---holley fuel pump---mallory pressure regulator---spare cages for uni filters---K&N air cleaners, with tops tapped for breather

box--that oh so smooth berg linkage cured a miriad of problems when it replaced hex bar on previous motor:thumb

[ Edited on 26-11-05 by dumone ]

hellbugged - May 2nd, 2005 at 02:57 PM

forced induction!, so thats why the idiots got three cams.

---IHI RHB5 turbo----intercooler----malpassi boost sensitive pressure reg---modulator rings, like velocity stacks but smaller only 31-36mm, used to

change air pressure at top of blo- thru carb under boost, thus float bowl and main gas jets to enrichen mixtures as boost comes on:jesus---rebuild

kits,two sets with rubberish gaskets again for life under pressure--just above the dellorto sticker are throttle shaft sealing o'rings to stop

fuel/boost escape again---turbo emulsion tubes, again boost, these allow running larger jets by leaning bottom and midrange passages--- 2.9mm ball

type needle and seats(berg)---quality gaskets---not going with turbo yet more parts and research needed

[ Edited on 26-11-05 by dumone ]

hellbugged - May 2nd, 2005 at 02:57 PM

no, no, must resist!

[ Edited on 26-11-05 by dumone ]

hellbugged - May 2nd, 2005 at 02:58 PM

ignition; top--electronic ignition control module--jacobs omni pac computer coil, this thing uses the earthed out coil(at bottom) as a signal and

automatically adjust spark accordingly, no i dont get it either but it has provided years off service on a 2180, two 1300s and a 1640 and contiues to

blow rotor buttons apart so there is certainly serious sparks happening---fuse box bottom left:kiss

[ Edited on 26-11-05 by dumone ]

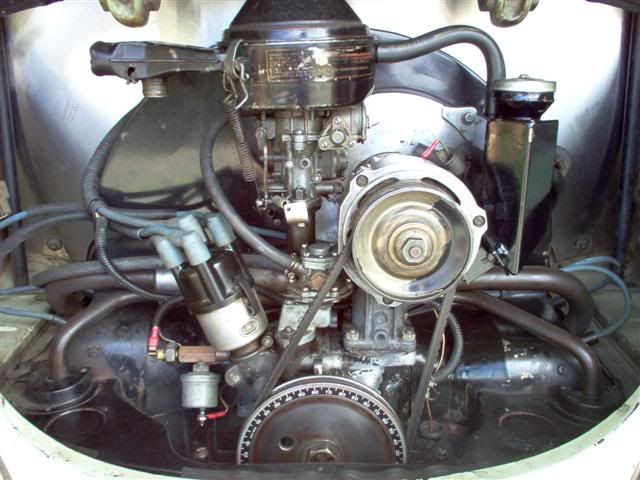

hellbugged - May 2nd, 2005 at 02:59 PM

1640; showing breater box--electronic 009---berg "acheiver" pulley, yep another spare part--36hp dog house fan shroud--senders set up----another dip

stick temp thing that earths out factory oil light when both cold and hot, yep berg--polished alternator:duh

[ Edited on 26-11-05 by dumone ]

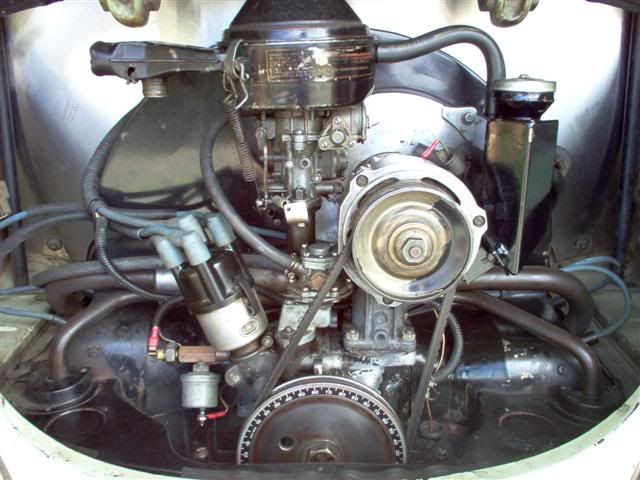

hellbugged - May 2nd, 2005 at 03:00 PM

this is where we should end up. hope a few people take an interest in the process and offer advise/ encouragement along the way.will be posting

regularly as i get going, hope the administrators don't mind (u2u if so) . not sure who will be doing what at this stage, there is a wealth of talent

in this area, from stan the man to retired hellbug proprieters, others too and its always nice to do a bit yourself!

cheers everyone thanx for sharing this with me, i really needed to tell some people who should enjoy

[Edited on 3/5/2005 by dumone]

Chewy - May 2nd, 2005 at 03:03 PM

porn!

Lookin forward to the build up

ruckus - May 2nd, 2005 at 04:00 PM

Looks like enough to build a couple of engines?

hellbugged - May 3rd, 2005 at 02:49 PM

the home for the all BERG 1776cc....

super tourer......

race day.......

a slideshow about "bugsmoney"s other mods....

http://s31.photobucket.com/albums/c365/dumone/?action=view¤t=1166511229...

[ Edited on 19-12-06 by dumone ]

56astro - May 5th, 2005 at 07:47 AM

1st dibs on any left-over parts

:P

Turbo54 - May 5th, 2005 at 09:35 AM

What are the specs on the turbo cam and how efficient is that turbo, how much boost, when does it come on?

Thanks

T54

hellbugged - May 5th, 2005 at 11:16 PM

| Quote: |

Originally

posted by Turbo54

What are the specs on the turbo cam and how efficient is that turbo, how much boost, when does it come on?

Thanks

T54

|

the thing is tiny, so i believe early boost is a cerainty, i'm not aiming for ultra high boost levels, 15psi is possible. they came off

telstars/mazda 626, so it wont be as efficient as whats available now. internal wastegate. pretty sure its the same as what dave becker was running on

his oval a few years back and shimo has fiddled with these as well. a mate is turboing a fiat motor at the moment, and a visit to his house made me

realize just how tiny my turbo is, i'll get a side by side shot with his, it'll blow you away. hes running a 100mm throttle body on a four cylinder,

huge!!!!

[Edited on 5/5/2005 by dumone]

Euro_67 - May 6th, 2005 at 05:13 AM

Someone needs to attend Gene Berg Anonymous, That is one serious addiction to berg products. All for good reason too, the quality is unrivaled.

Wayne.

Brett - May 6th, 2005 at 07:59 AM

Most of that went over my head. I just finished a top end rebuild, all standard stuff. I look forward to regular updates, and plan to learn as much as

possible.

Brett

pete wood - May 6th, 2005 at 11:28 PM

Are you really using carbs with a turbo?

Why?

hellbugged - May 7th, 2005 at 08:46 AM

Pete, carbs and turbo-machining the throttle shaft area is the only mod that could send them to the useless pile. the other stuff can be changed back.

if life was perfect, injection would be the go. the whole turbo thing is a serious commitment, i know. i'd still go for twin blow thru either way. so

hats and exhaust, inlet pipes,etc will be first on the list,whilst i think it over.motor will be run with out turbo initially.

cheers damien

pete wood - May 7th, 2005 at 09:39 AM

| Quote: |

Originally

posted by dumone

if life was perfect, injection would be the go.

|

how do you mean?

you've already got the manifolds, if you sold less than half the stuff you've got you'd have enough for a great computer and a set of throttle

bodies. Then all you gotta do is tune it. Just a thought

hellbugged - May 7th, 2005 at 04:16 PM

Pete, $$$ i mean.getting to the end of the budget for now.working on some one who is removing a pair of throttle bodies, another freind has suitable

injectors, so it might head off in that direction yet.got an estimate on how much its worth to go to injection? or who to contact?

thanks damien

pete wood - May 7th, 2005 at 06:28 PM

as I understand it, the expensive bit is actually the dyno time. A good computer is only $1500. CBB now have a dyno, and they've done efi VWs before,

so might be worth talking to them. Another one is wayne penrose. His dragcar build up is in the Darg racing section at the mo. He could tell you a few

things.

But what it boils down to is this. Carbs are always gonna be limited and less precise than EFI. With carbs you might get 200hp at 6000revs, but not

much anywhere else in the reve range. With EFI you'll get as close to perfect tune as pos across the ENTIRE rev range, even with a very lumpy cam. It

also helps you tune better to avoid detonation, and that will really save you bucks.

hellbugged - May 8th, 2005 at 08:42 AM

the missus says your a bad influence Pete.$1700us for C.B performance setup, sounds reasonable?

tar damien

[Edited on 7/5/2005 by dumone]

ruckus - May 8th, 2005 at 12:18 PM

Any more details on the cb kit?

+++Edit+++

sorry found it:

http://www.cbperformance.com/catalog.asp?ProductID=281

I assume this is what you meant?

Or this?

http://www.cbperformance.com/catalog.asp?ProductID=286

I was just being lazy again

[Edited on 8/5/2005 by ruckus]

[Edited on 8/5/2005 by ruckus]

pete wood - May 8th, 2005 at 10:03 PM

nah, use an Aussie ECU. Better product and user support. Also, keeps aussie bucks in aussies companies.