Creative Safari windows and 6 popouts installed...

creative IRS kit ready to be installed....

engine horns removed , ready for welding in new ones.

ooops...sorry about the double up...

[img]http://img.photobucket.com/albums/v365/deca000/080205109.jpg [/img]

IRS installed and painted with POR15

Rear brakes from 1969 restored, new axle bearings seals ect...

adjusters installed in front beam

reversed link pins. I had an engineer machine and make up new os brass bushes. Also reversed tappered tie rod ends to fit later type.

wide five with link and disc brakes....

wide five with link and disc brakes....

bus is finally on its own wheels and rolling. Time for body work...!.tyres are 185 55, had to do some minor guard rolling to clear the rears.

great stuff!:thumb

Nice, looking sweet

Hey that is going to be a real sweet ride, good on ya for putting in the effort to do a top job.

Questions, I am not familiar with splits. The picture with the two small square chassis beams. Is that the motor/ gearbox area and what conversion is

it for? If any? I am just curious as that is the kind of work I love to see.

I have a great respect for any mechanical engineering work.

With the Creative Engineering IRS kit, you have to replace the engine/gearbox horns to fit the swing arms. The concept is that it gives you full

suspension travel like a bay set up. Alsothere is clearance for the cv joints. The hardest part of this mod is to make sure all your measurements are

correct before welding.

That looks awesome 58 and got me inspired

I am doing same to 66 panel as we speak but still in pull down stage

Using all the same brands too

Keep the pics coming

looking good.Waht front brakes are those?

Front brakes are kit from Volks Conversions

Very happy with the set up and quality.I think its worth spending the money and having it done right the first time.

That's going to look awesome when finished!  Definitely love all those pop-outs.... want to get mine in now!! :P

Definitely love all those pop-outs.... want to get mine in now!! :P

nice mate, keep the piccys rolling

Hi, im currently doing a '58 bus.

I'm currently exploring lowering options, what tranny did you end up using? What are the options with the creative kit?

Can you point me to some more info for what you did with your front spindles?

cheers,

James

great stuff derek!!! come along way since i last talked to u!! so she going to be done by chrissy?? come on mate 3 weeks left get it oner and

cruise!!

cheers

rhys

With the IRS conversion I have a single side plate gearbox out of a 71 beetle. These gearbox's have a better top end ratio.

The engineering and quality of the Creative Kit is awsome.Well worth doing.The options you have with this kit is you can run either standard late

spring plates or do what i did and run with the supplied adjustable ones. You still need to run beetle gearbox with a combination of beetle CV joints

and Bay bus shafts and CV joints . I chose to run rear hubs and drums from a 69 model because i wanted to keep the wide five stud pattern. You can run

later brakes and 4 stud patten if you wish.

Front spindles. I used a press from work to press them apart. You need to find an engineer shop to do the required machining to reverse the link pins.

I had them machine the shafts and make up oversize brass bushes. You have to clearance the centre pin against the stub axle .(enough to fit 5 - 6

shims) Some people weld a gusset on the other side for strength. I dont think you need to, as the link pins are heavy duty and good quality steel.

This gives you 2.5" drop without changing any of the steering geomerty. I reverse the taper on the ball joints. Honed them out to fit bay window ball

joints, so they clear the chassis. I also installed adjusters.

3 weeks! im chewing up the funds real quick....

should be painted before winter. then it will be a down hill run form there.. i just got all the rules and regs today on installing seat belts.. will

post some pictures as i go ...

Installation of aftermarket seat belts. Required by RTA (Vehicle inspectors bulletin 49)

* An engineer's certificate must certify the fitment of the seat belts.

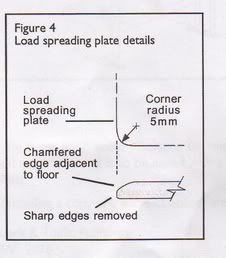

*Load speading plates (mounting plates under floor ect.)should have a minimum area 3750mm squared. (75mmX50mm)

*Thickness should be no less than 3mm

*All corners should have minimum radii of 5mm

*Edges adjacent to the floor are to be chamfered (this is so the mounting plate wont wear through the fLoor.)

Sprayed etch primer today on RH side. Love that fresh clean painted look. Also welded up fuel tank guage hole in dash. Were these gauges fitted by the

selling dealers. ?(They always look out of place on the dash. )

This bus has only minor rust repairs done to it.The panels are straight as they come. The bus still had the original shocks fitted to it, and the foor

sections have not one single dent in them. I dont think this bus has done much work in its life.

Nice to have a good canvas to work on.

recieved my new rear brake drums toady. That makes everything in the brake department brand new. Want this bus to stop as fast as it will go. Couldnt

help myself, gfave them a coast of hi temp gloss black to protect them....

started on my seat belt mount plates but got destracted by this....

then back to more of this......

six done, six to go ,then drill and weld nuts on them. plus 2 for the sash part of the seat belt.I used 5mm flat bar , the min says 3mm.Felt it safer

for the uupper part of the fron belt mount as it will be 30mm wide and not 50mm.keep a bucket of cool water when rounding corners on the bench

grinder, these peices get real hot to hold, fast......

#! Message No Longer Available !#