Turbo charging Type IV

effvee - February 15th, 2007 at 03:18 PM

Hello, I live in the US. My choice of VWs is the Super Beetle. I'd like to make it a kind of GL, but with a "this side of the pond" after tast. At

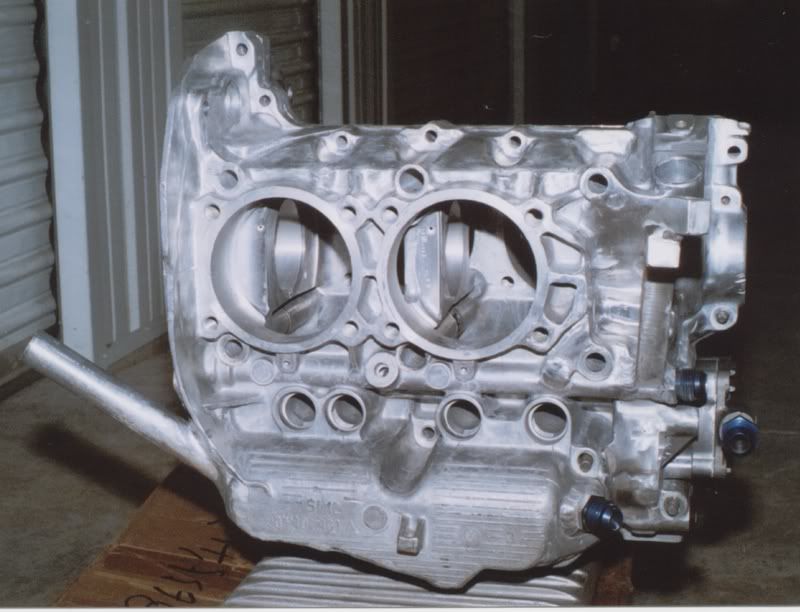

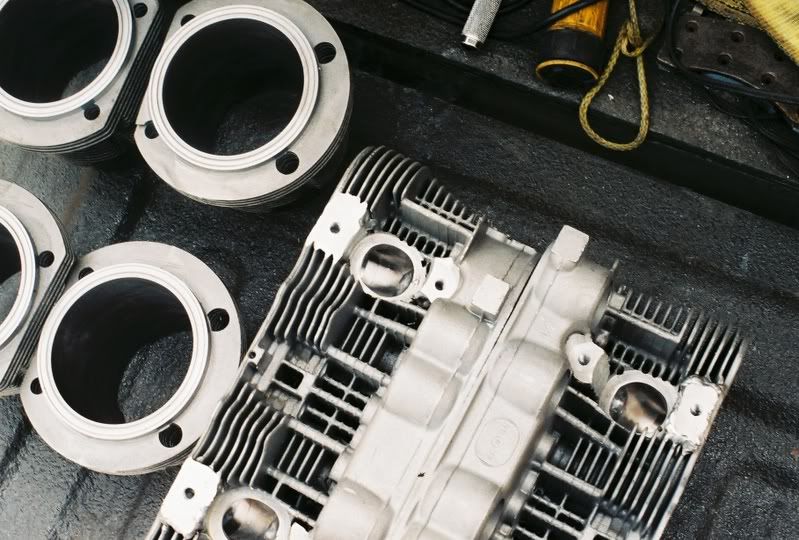

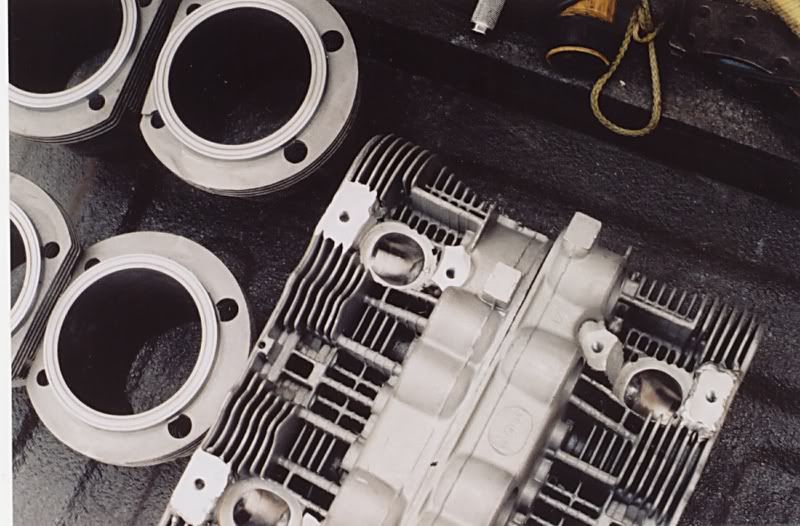

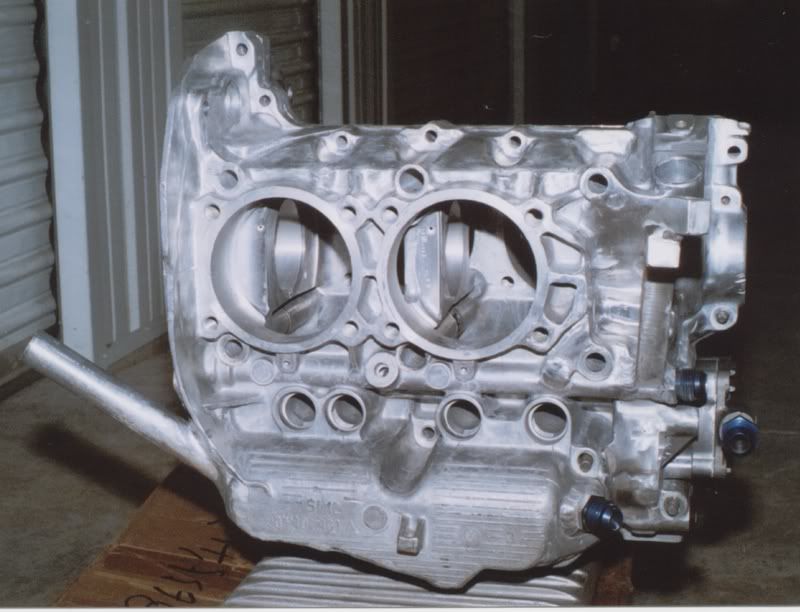

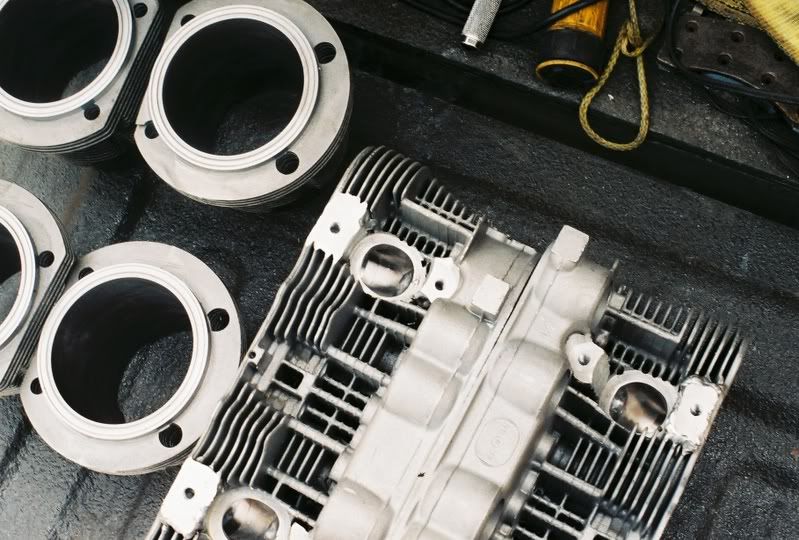

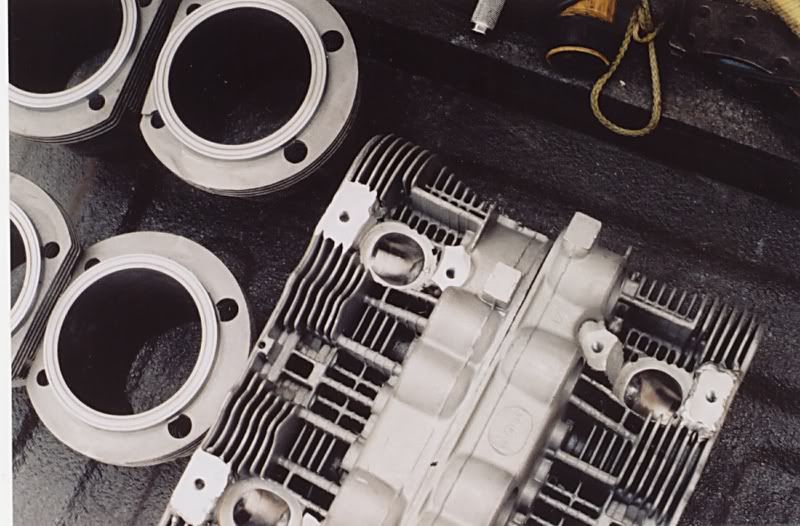

least 2.4 86X96 steal cylinders with 2.0 heads. I had Rimco do the machine shop type of work, but I did the porting. I had the heads double O ring

grooved for brass sealing "O" rings. The case is highly modded, form making a part and having Rimco weld it for a extra type one sump. Also the

case has no internal pressure releif valve (it will be external)

See what I mean about the case being modded for type one extra sump.

I also had the case modded for oil squirter.

Dual turbo, dual intercooler as well

[ Edited on 15-2-2007 by effvee ]

[ Edited on 15-2-2007 by effvee ]

[ Edited on 15-2-2007 by effvee ]

[ Edited on 15-2-2007 by effvee ]

VWCOOL - February 15th, 2007 at 03:51 PM

jeez!

bond - February 15th, 2007 at 04:17 PM

nice - look forward to watching this post - keep up the pics!

nick

effvee - February 15th, 2007 at 04:30 PM

Well I have not welded the bracket to the external pressure valve, but here it is. O sorry for the color of the picture, was a cheap camera

The heads are ported by myself, had to relocate the exhuast studs, because while porting, I found out in order to have the heads Cryoed all the studs

have to me removed. The stud area was close to the studs and when I tried to remove the studs, the holes just distorted. So I had the good people at

Rimco weld up and raise the stud area.

[IMG]

http://i86.photobucket.com/albums/k97/effvee/IMG_0015.jpg[/IMG]

Don't want to bore you with alot of engine work

[ Edited on 15-2-2007 by effvee ]

[ Edited on 15-2-2007 by effvee ]

[ Edited on 15-2-2007 by effvee ]

[ Edited on 15-2-2007 by effvee ]

[ Edited on 15-2-2007 by effvee ]

[ Edited on 15-2-2007 by effvee ]

bond - February 15th, 2007 at 05:49 PM

LOL insane

nick

Dasdubber - February 16th, 2007 at 02:47 PM

You are certainly not boring me with "engine work"! The more info and pics the better!

What are your plans for exhaust stubs? I know the pushrod tubes can potentially limit the diameter of the stubs coming out of the heads....

Also can you divulge any more info about your turbo and intake (EFI vs carbs etc)?

So many questions but I don't want to bombard you right away!

Alan

effvee - February 16th, 2007 at 02:55 PM

| Quote: |

Originally

posted by Dasdubber

You are certainly not boring me with "engine work"! The more info and pics the better!

What are your plans for exhaust stubs? I know the pushrod tubes can potentially limit the diameter of the stubs coming out of the heads....

Also can you divulge any more info about your turbo and intake (EFI vs carbs etc)?

So many questions but I don't want to bombard you right away!

Alan

|

Hi, well the turbos will be from a Goe Metro. So it will be two turbos intended for one liter engine. There is a company called Turgo City in the

city of Orange, CA. When the time comes, I may have to choose different inpellers. I have to do alot of reading here one source

These throttle bodies are only .090 larger than normal carb bores, (nothing for a milling machine)

The intakes by BAS allow you to reverse the throttle in order for the injectors to bo on the inside.

I will use Mega Squirt for a control system.

The cast iron cylinders are old 94s open to 96s. Also the sealing surface I had extra metal spacer made, so the internal 96 bore is really 102 outside

sealing surface. The grooves are .042 in U S meausement. The heads has a .019 groove and the cylinders has a .019 either of which there is a .006

crush..

Also the exhuast ports have been opened up more since this picture. I have not taken any more picture of late. The stub pipes are under way, it seem I

have to make everything form scratch. They are made from half inch steel flame cut out to the shape of the exhuast port. Sorry no picutres yet also. O

the oil pump is either a 32mm or 36mm pump thus the remote pressrue releif valve.

This pressure releif valve is from a RX-7 regulated at 80psi

So it supposed to come out of the pump very high pressure to a dual high pressure fork lift hydrulic filter, thourgh the filters, to external oil

cooler, then into the regulator where it will be regulated down to 80psi. So the three -10 AN male fittings are one for the pump out then from the

regulator into the main oil galley and the third fitting in the sump is for return. The return will come from the bottom of the pressure regulator to

the sump. I also think I will have alot more filterd oil because of the by pass into the sump. (Au I hope:o )

[ Edited on 16-2-2007 by effvee ]

[ Edited on 16-2-2007 by effvee ]

[ Edited on 16-2-2007 by effvee ]

[ Edited on 16-2-2007 by effvee ]

type3lover - February 16th, 2007 at 07:59 PM

More! I wanna see more!!