[img]

[/img]

[/img][img]

[/img]

[/img][img]

[/img]

[/img]

well after buying this 2 owner bug a little over 5 years ago.

it sat in my mates garage collecting dust. after getting

engaged i decided i wanted one of my cars as the

wedding car. so i dragged the bug out of my mates

garage (literally, the brakes were seized to the drums).

we put it on the trailer and bring it home. the very

next day we took the body off the pan. then it sat for a few

weeks. the weekend that just went we stripped it of all

paint and glue from interior. pics to come. it will be going

back to origanal paint and interior theme(black with red

interior) ill put my 16 inch fuchs and my 2332cc engine.

hope you all enjoy my build. forgot to mention needs to

be finished by april next year.

here is some pics

[img] [/img]

[/img]

[img] [/img]

[/img]

[img] [/img]

[/img]

the only rust i have is in the drivers side rear wheel arch

where the guard bolts on and the rear bumper mounts.

[img] [/img]

[/img]

[img] [/img]

[/img]

[img] [/img]

[/img]

the body off the pan

[img] [/img]

[/img]

[img] [/img]

[/img]

just a few more

i will post more pics during the week.

bit of an update. monday and tuesday night and tonight

i have spent in the garage. 90 percent of the car is now

bare metal and the roof is in etch primer.

have any of you come across this marking/stamp on a bug

it was on the roof on the bare metal.

a few more pics

and some more

some pics of the parcel floor and heater channels.

i cant beleive not one bit of rust there.

looking good keep us up to date

looks like its coming along nicely...

thanks guys. does anyone know what that stamp on the

roof was for???

I haven't seen that stamp before - I certainly didn't see any such marking on my '64 years ago when it was stripped back to bare metal.

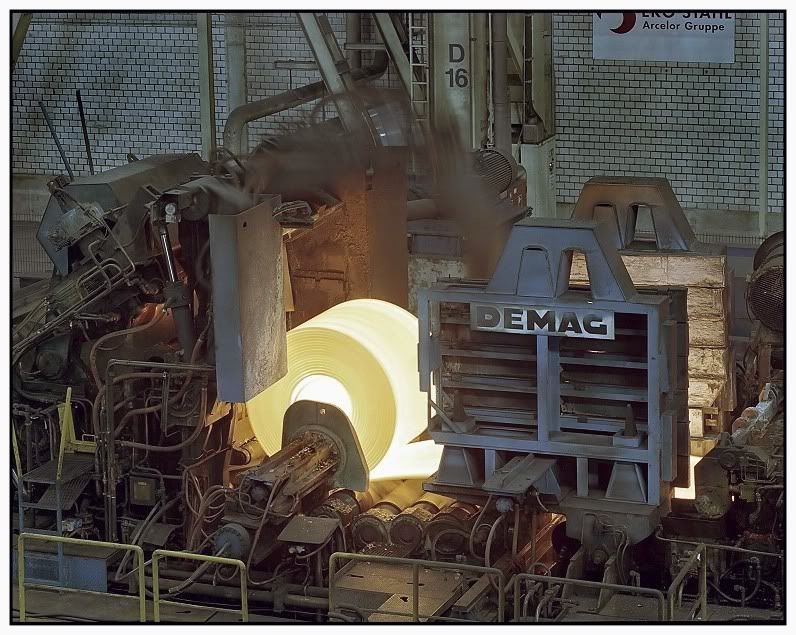

My guess is that it is a manufacturing stamp for the steelmakers who provided the rolled steel to the Volkswagen plant in Melbourne. The Clayton

factory was fully equipped with giant hydraulic presses to cut and stamp the VW body panels, as well as having the first body master jig outside of

Wolfsburg. The Clayton plant would have purchased and used rolls of Australian-made sheet steel, and I think it's a manufacturer's stamp on the

sheet roll.

Does the marking say 'CPS' or 'CRS'? If it is CRS it could stand for 'Commonwealth Rolled Steel'. The Commonwealth Steel Company was based at

Waratah, Newcastle, and became part of BHP in the 1970s.

thanks heaps phil74camper, very informative information.

yeah its CRS, good to know where vw australia got there

sheet metal from. well now i know about the mystery

stamp. well i done a little extra work on the bug. i got my

brand new 2 inch narrowed beam. and i have tared the

inside of the floor. the bottom of the floor is getting

painted.

CRS is an abbreviation of the manufacturing process, it stands for Cold Rolled Steel. In this process the steel is pressed between

two rollers to achieve a uniform thickness. When metal is worked below its 're-crystallisation' temperature it is said to be 'cold worked'.

However, the metal may be purposely heated or still quite hot from another forming process such as hot rolling or forging.

Lysaght were suppliers of steel to VW Australia, in the '60's when full local production was happening, it probably arrived by train at the Clayton

factory in "coils" like this:

They would have been fed through Clayton's huge presses to be stamped into various body panels. I can't see Lysaght going to the trouble of re-

rolling the coil (once it's been formed) just so they can put a stamp on every few feet. So, I would imagine the stamp was applied just to the

outermost roll of the coil (for product identification) once it had cooled.

So, your roof skin seems to be lucky enough to have been pressed from the first few yards of a Lysaght coil as it was fed into the panel press at

Clayton. The stamp was protected by the initial phosphate coating used in the factory on bare metal, there would have been no need to sand the stamp

off as there were four coats of paint to come, so the stamp had no chance of showing through. Being only at the beginning of the coil explains why

people don't find these stamps too often.

| Quote: |

WOW. that is awsome matt. i thank you heaps for your time to write so much about the process, very informative stuff there. good to know im learning quite a lot on the history of my car. thanks heaps.

Looks great man!

Out of interest, what did you use to get the remnants of the hessian insulation off the rear parcel area? I've got all sorts of rubbish still stuck

to mine.

i used a wire wheel then used a plastic sanding wheel. worked really well i had it done in just an hour