59 11 window Custom Resto

Dasdubber - December 1st, 2010 at 07:56 PM

Its been a while since I've posted much in the members ride section as I've been so busy with customer's cars and not my own.....and although this

is a customer's car, I felt it was too good not to post.

I'm not trying to drum up business by posting all these pics as we have heaps on for quite a long time in advance, however I thought members would be

keen to see what has gone into this amazing bus.

It started out life as a kind of solid 1959 Microbus that the owner purchased from Steve Muller at Kombi Rescue.

Before I dive into a heap of restoration progress pics, I'll fast forward a little over 12 months of solid work to where we are now....not far from

paint...

Here is where we are at the current day...

Cheers

Al

Bizarre - December 1st, 2010 at 08:13 PM

damn Fuchs suit a split

Great work (as usual)

squizy - December 1st, 2010 at 08:51 PM

Drum away Al, drum away. Looks way cool.

Dasdubber - December 1st, 2010 at 08:53 PM

Cheers mate.

Like a lot of 50 plus year old buses, there are always lots of stubborn screws - rather than drilling and retapping all threads, where we can we use

heat and then water/air to expand/contract the screw/screw plate to help uncrack them

So often people will assume "the rust is not too bad" when they can only see a small pin hole or two, but this is more often than not what is hiding

underneath...

After blasting

The start of one of the major custom mods of this resto....a walk through conversion

A lot of Gerson repair panels went into this bus

Shaping walk through backs/sides

Dasdubber - December 1st, 2010 at 09:01 PM

A hell of a lot of time was spent gapping the doors and apertures throughout the welding stage

Although they are the best of what is available, even the Gerson panels do require some tweaking to get right....nothing is just a straight 'chop out

he old, weld in the new'

Turbo54 - December 2nd, 2010 at 01:30 PM

Why cant you be in Adelaide!

Mad job as always. When everyone talks about how good the paint is and never comment on the gaps, panels and all your hard work, just keep telling

yourself it is all in the prep.

Well done Al,

Heath

dubai - December 2nd, 2010 at 02:45 PM

I saw this one at the Run to the sun its really a nice job and I know that the end result will be awesome. good work Guys

jjwebb123 - December 2nd, 2010 at 07:27 PM

Nice work,we have a similar project about to start.

is that sand or sodablasted?

did your blast/prime the inside?

Cheers

Dasdubber - December 2nd, 2010 at 07:54 PM

Thanks guys. The bus was sandblasted by a guy who only does classic cars and hence knows what he is doing (has never warped a panel on any of our

restos). He blasts the inside too but does not blast the inside surfaces of the exterior panels (ie inside door skins) but does the ribs/framework. He

has found blasting the inside of the skins increases the likelihood of warping considerably.

Heath, as rad as Adelaide is, I think I'd miss the warm water and surf up here too much

Hope you're well mate.

Al

Dasdubber - December 2nd, 2010 at 08:16 PM

There are a lot of subtle (as well as some not so subtle) details on this bus including modified jacking points to keep the lines clean on the side of

the bus as these are not very attractive in stock form. A bottle style jack will be used (if necessary) on the chassis rail (strengthened) but the

jacking point has been 'cut and shut' so it can still be used a hoist lifting point

Lower windscreen sections had to be replaced as well

A donor door provided a replacement lower section (inner)

And a Gerson section plus a hand formed piece completed the rust repair on the outer skin

Lots of plug welds required for the cargo floor section

RHD locking ball handle Berg shifter is the ducks nuts

The start of the custom air conditioning installation

Another custom touch was the dash treatment including a glove box

vw54 - December 2nd, 2010 at 08:18 PM

bloody hell Al U have time to SURF as well ???

Top stuff

Dasdubber - December 2nd, 2010 at 09:00 PM

Not as much as I'd like to Dave - I thought running my own business would give me more time to surf when its 'on'....sadly thats not the case! At

least I do what I love for a living so that is the trade off

Dasdubber - December 2nd, 2010 at 09:09 PM

The start of the air con evaporator (blower unit) cover

Lots of little details like filling in the original brake fluid reservoir access hole

And fabricating a new heater duct

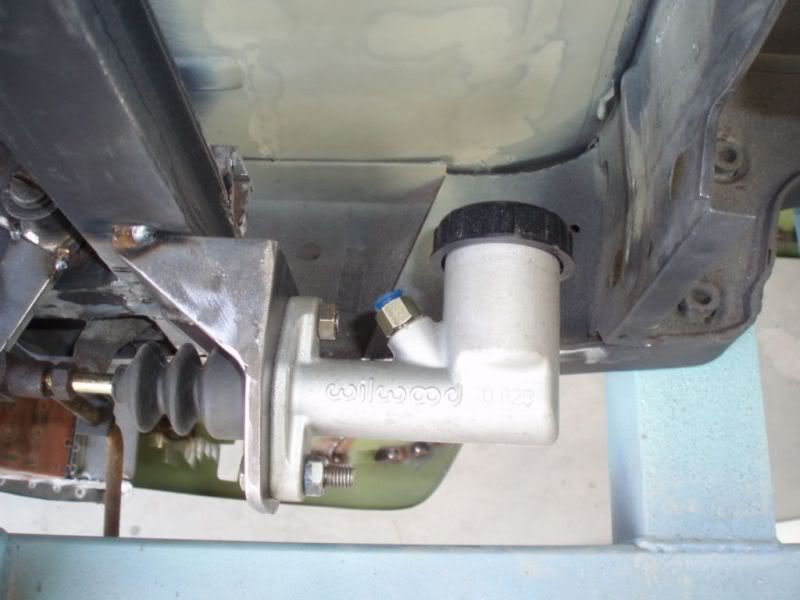

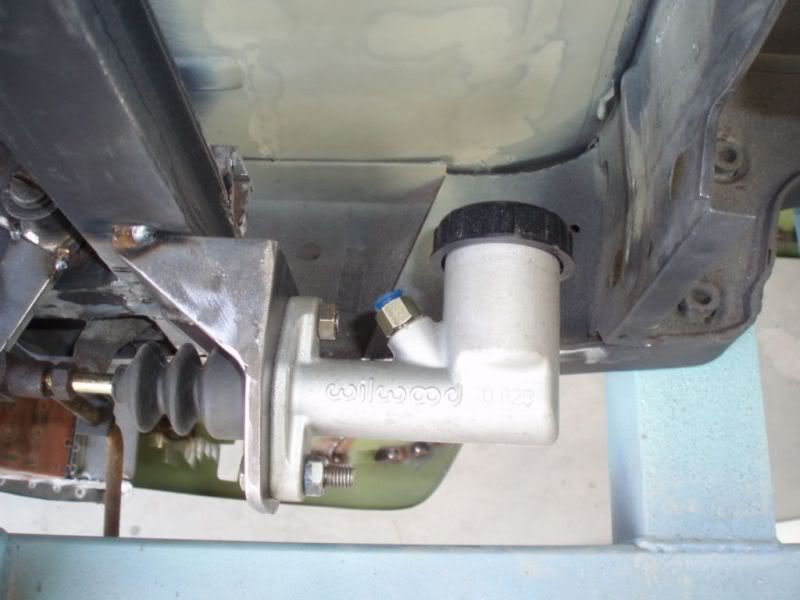

Hydraulic clutch

One amplifier is mounted behind each front seat and is covered (more details later)

As the owner is a cyclist, he requested we integrate bike mounts (x2) in the rear cargo area that fold away under the floor so remain hidden when not

in use

Deluxe bumper trim has been installed on both bumpers

More dash work

ricola - December 3rd, 2010 at 04:11 AM

I remember reading another more complete build thread for this somewhere, where was it? I need more, lol!

57 Chook Shed - December 3rd, 2010 at 02:46 PM

Excellent work mate!

GASBNR - December 3rd, 2010 at 04:46 PM

very cool AL are they 18's

very cool AL are they 18's

Dasdubber - December 3rd, 2010 at 05:21 PM

| Quote: |

Originally

posted by ricola

I remember reading another more complete build thread for this somewhere, where was it? I need more, lol!

|

I've had one going for a little while on SSVC forum but have full pics (close to 1000 already) on my website:

http://dasrestohaus.com.au/gallery2/main.php?g2_itemId=4742

Ol, Fuchs are the Iozzio custom 17in (18s probably would have looked a bit big on this bus).

Cheers

Al

DieSchnelleKafer - December 3rd, 2010 at 06:48 PM

woa my jaw is sitting on the floor, are they 17 fuchs from pete?

Dasdubber - December 3rd, 2010 at 09:25 PM

Yep 17in Fuchs are purchased through Pete Skiba at Airkewld but manufactured via Paul Iozzio - both very nice guys whom I met in the US.

Dasdubber - December 3rd, 2010 at 09:55 PM

After quite a few hours the glove box door was close to completion

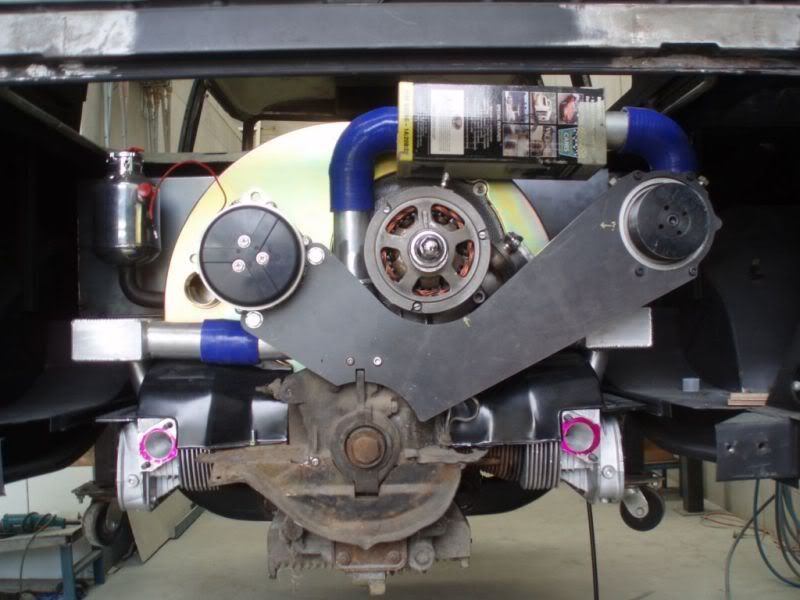

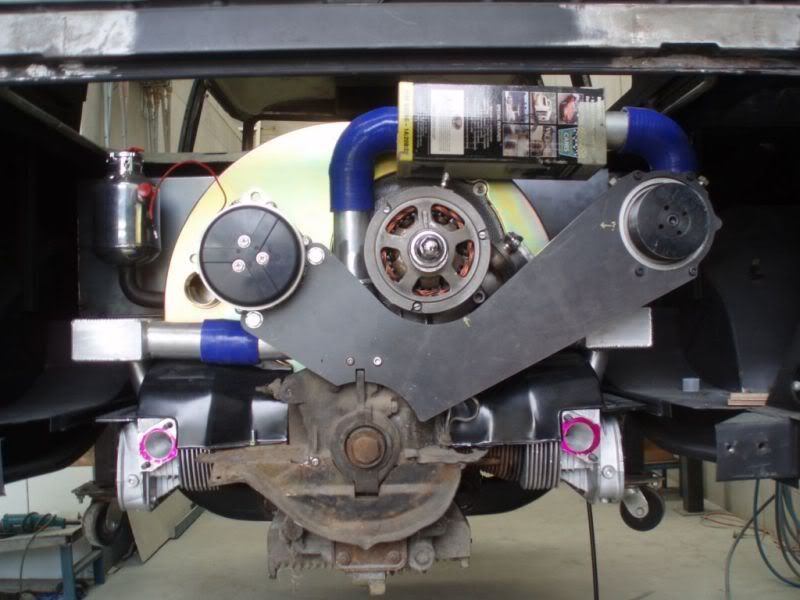

Coolers underneath the bus include the AC condensor, engine oil cooler and intercooler radiator (all with thermo fans mounted above coolers) plus

small supercharger oil cooler - cable conduits/tubes etc have been relocated to allow fans to be mounted on top

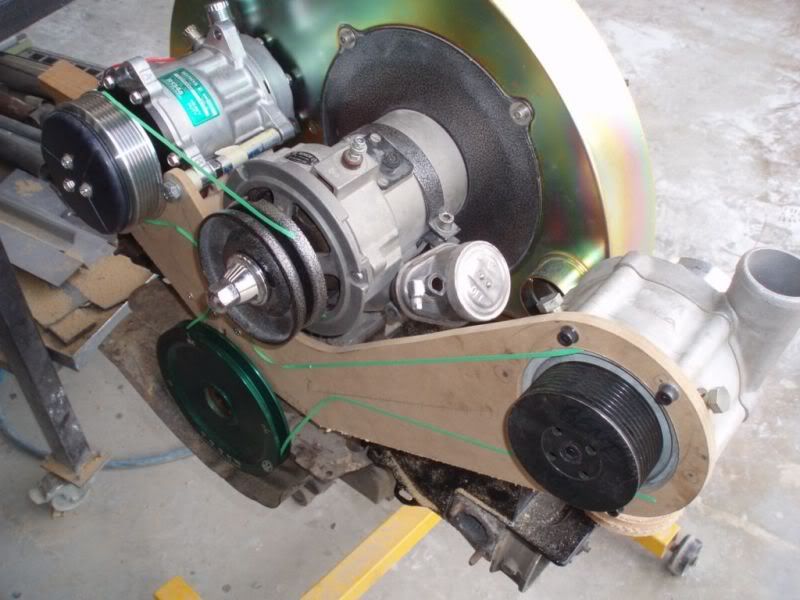

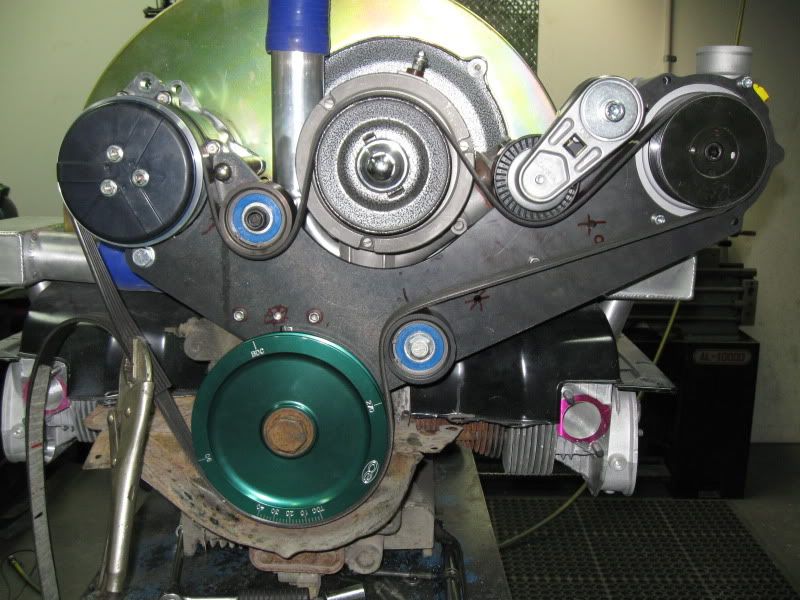

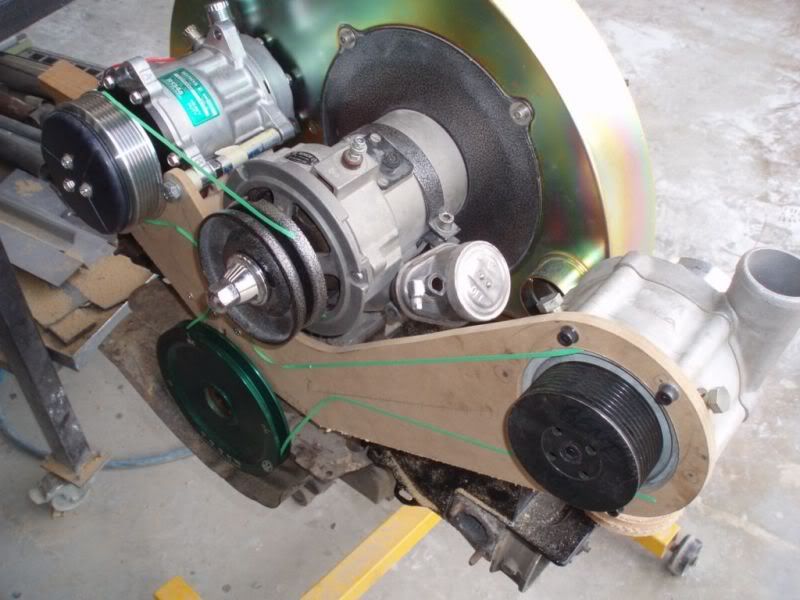

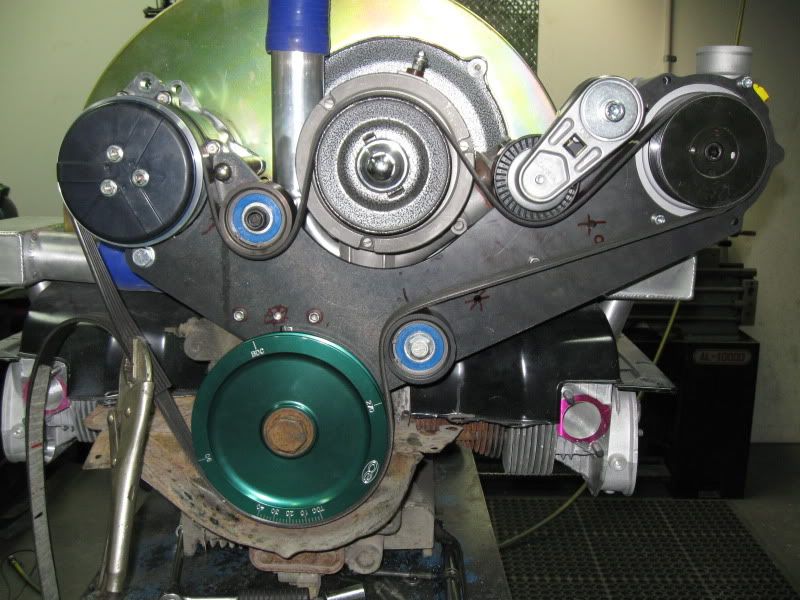

Speaking of the engine, it will be a 2275cc type I based motor (longblock built by Leon's Motors) with AC compressor, single throttly body (coupled

to Link G4 ECU), custom water to air intercooler, and a Rotrex supercharger which will produce around 7 pounds of boost. This was fairly early on in

the mockup stage

jjwebb123 - December 4th, 2010 at 08:44 AM

more more more.

this is my fav thread on the forum right now.

Dasdubber - December 4th, 2010 at 11:56 PM

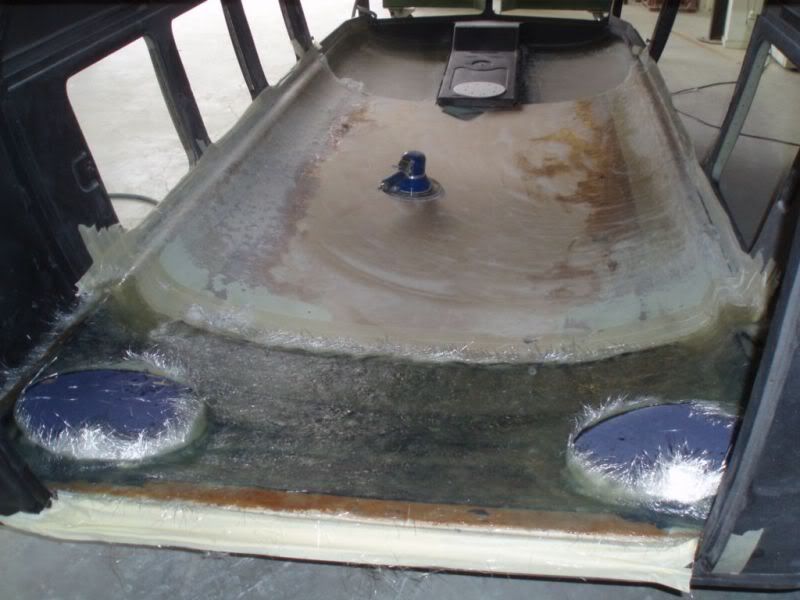

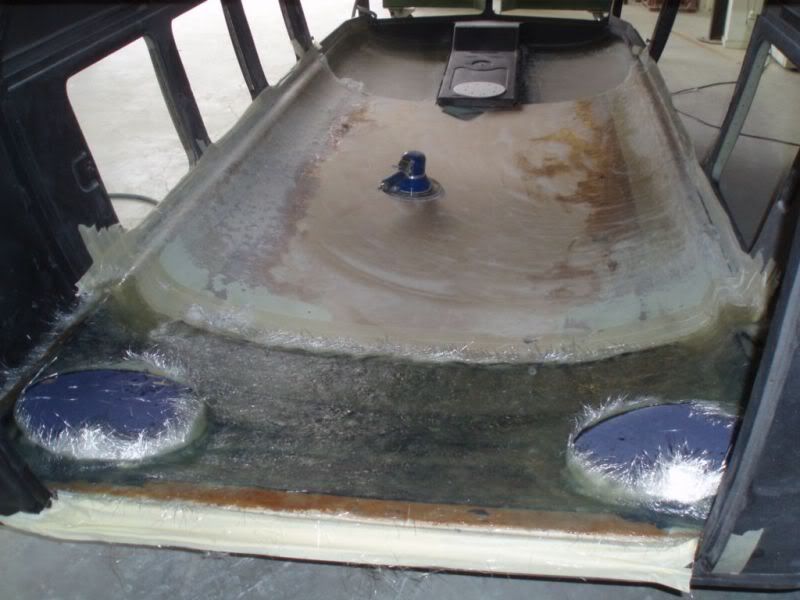

The start of the custom roof lining (fibreglass/mdf) with the rear sub box (sealed enclosure) housing the 2 10in subs.

Itchy stuff....

Front sections

A T3 engine access hatch was donated to the cause to make engine access easier (funny that)

Lots of time metal working the panels before filler work ensued

Al

Dasdubber - December 6th, 2010 at 10:01 PM

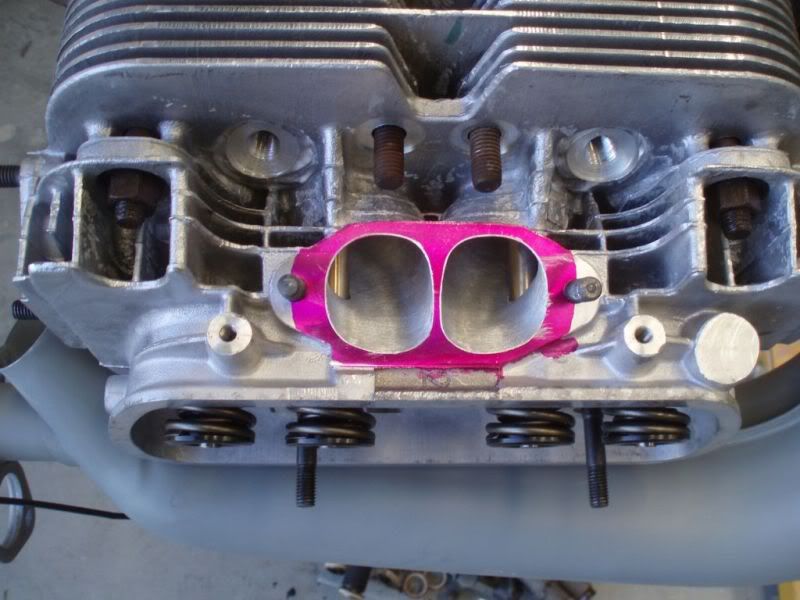

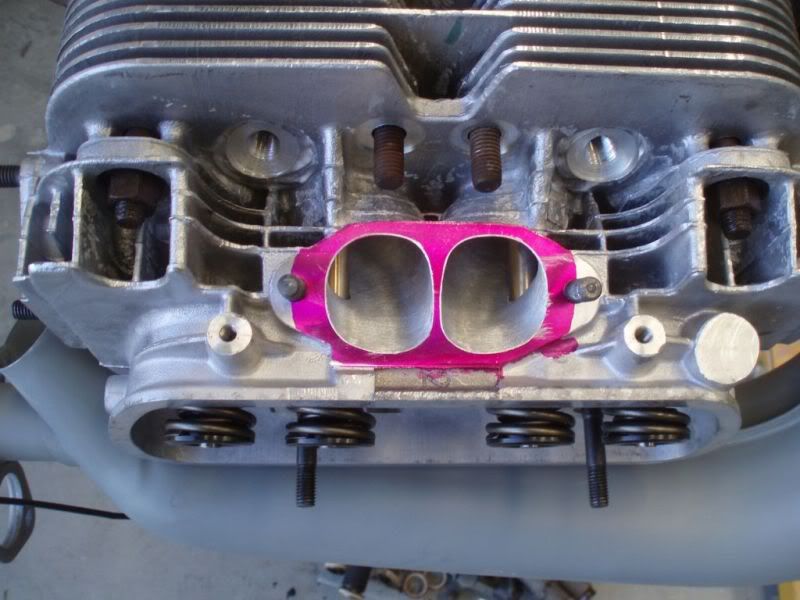

Plenums for fuel injection runners ended up rectangular as height was an issue under the supercharger

Top of runners were bellmouthed into plenums

Wedgeports were selected by Leon's Motors

Another engine mockup with cardboard intercooler for dimensions

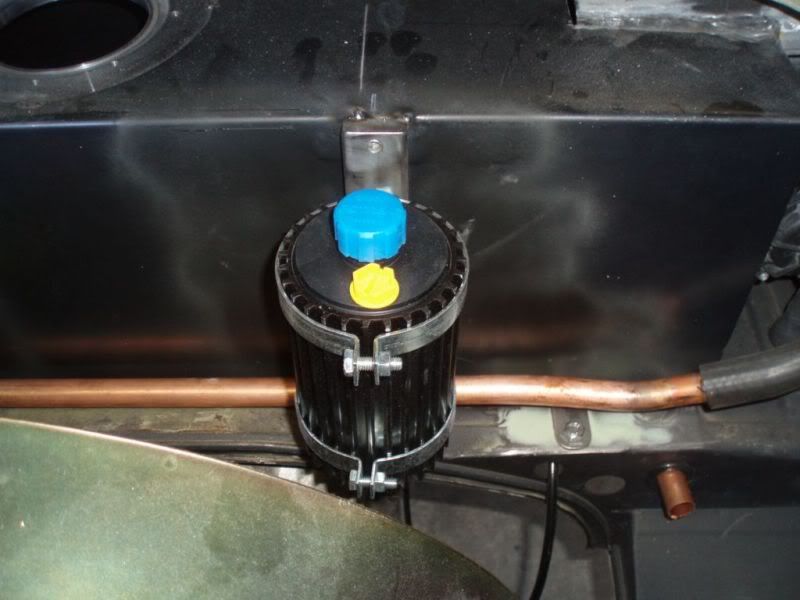

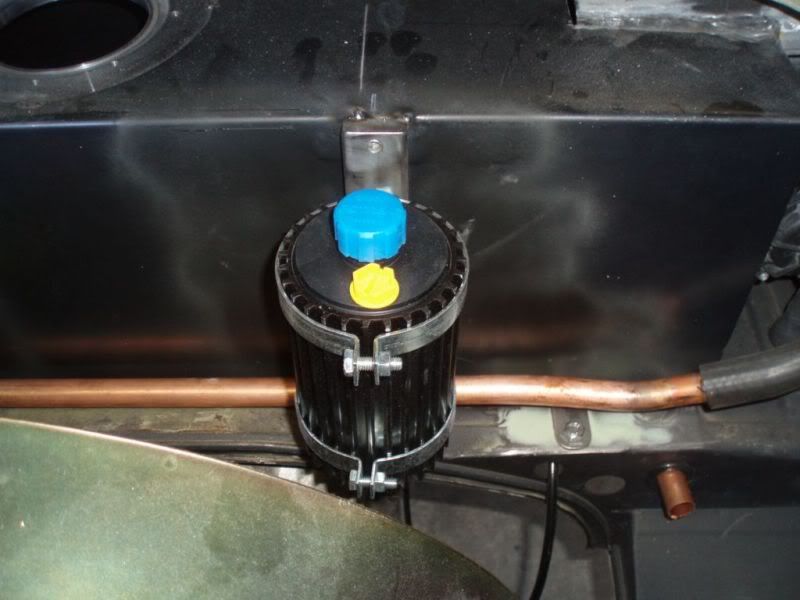

Intercooler water pump

Intercooler water reservoir

Supercharger oil reservoir

More bare metal work before filler is applied

vwsteve - December 7th, 2010 at 08:41 AM

wow, you are a very patient man, a lot of hard work there

Dasdubber - December 9th, 2010 at 09:17 PM

Cheers Steve, I am sure you can appreciate how many hours this custom stuff chews up!

Speaking of which under the passenger seat we integrated a fire extinguisher mount which is on a hinged door

The first to be installed in Australia - a Red 9 Design double wishbone front end which incorporates rack and pinion steering (yes we have liaised

closely with an engineer who is overseeing the whole rebuild including the vast range of modications)

The shifter was relocated backwards for both better comfort and also to give more room when in first and third (for clearance to the air con vents)

A mid mount was fabricated and chassis horns and gearbox cradle have been boxed for extra strength

A custom spacer was machined to fit an aero-style filler cap and neck

Obviously in mockup stage at this point but the new filler/tank setup has a block back vent (to relieve pressure whilst filling) as well as a rollover

vent which allows the tank to breathe but blocks if there was ever an accident and the bus ended up on its side/roof

squizy - December 9th, 2010 at 09:42 PM

Brilliant.

vwsteve - December 10th, 2010 at 06:39 AM

love the new front end

amazing work

cam070 - December 10th, 2010 at 09:02 PM

This is awesome. Can't wait to see more.

Euro_67 - December 11th, 2010 at 11:19 AM

Al I Havent been on here for ages, great to see your working hard and attention to details and creativity is brilliant as always.

I would love to have you work your magic on something for me one day......

Dasdubber - December 14th, 2010 at 12:10 AM

Cheers gents.

Couple of quick vids....

Fire extinguisher door:

Storage draw under drivers seat

Solenoid operated glove box door:

Roof bare metalled

Cover plates for custom walk through conversion

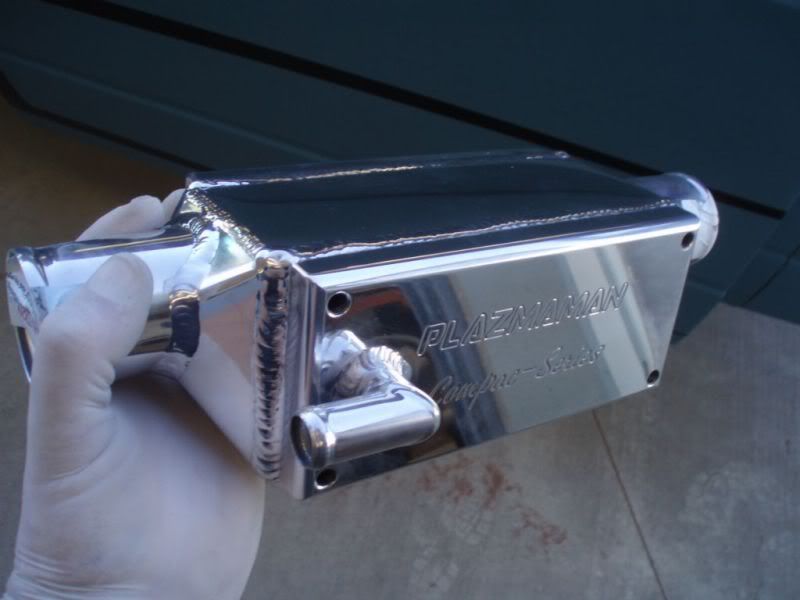

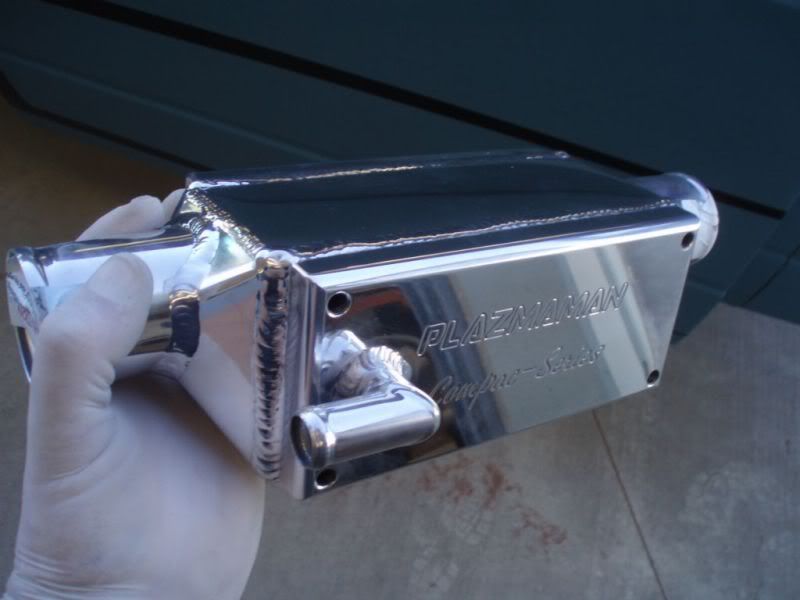

Custom Plazmaman water to air intercooler

Another mockup of engine with first version of laser cut steel face plate

To get the fatter wheels in the back with wider rubber and deeper dish, the rear torsion housing had to be narrowed

More pics to come soon

Al

very cool AL are they 18's

very cool AL are they 18's