done a search and found plenty of info for i.r.s., but has any one done this conversion on short type swing axle beetle's?

what i have;

ea caliper brackets converted and shaved to vw axle tube/bearing cover

late t1 drive flanges machined to ea disc size and shortened to swing axle length at axle nut area

ea disc rotors machined to correct wheel stud pattern

new ea calipers, pads and hoses

info on how to convert handbrake lever on calipers to use vw cables:thumb

now i need to know what problems may arrise before i pull the bug apart (daily driver), to make the converson as quick and easy as possible

specifically;:jesus

any clearence problems associated with swing axle, not usually struck with irs

any problems expected with wheel offset and how to cure

-currently running late drums on swing axle with perfect clearence inside and out

any differences/problems between brake hose location on swingers vs irs-realizing the irs hook up is supposedly straight forward

any info on bias issues using type i calipers on front with duel circuit master cylinder (type 1) that people have come across.

who knows what? any links appreciated too!

thanx

[ Edited on 5-7-06 by dumone ]

[ Edited on 23-10-06 by dumone ]

No-one has done it because swing cars can't be made to go hard enough to warrant big brakes! :P

The EA brakes should end up within about 2mm of VW track width, so no dramas there. I can't see any problems... except the fact the calliper brackets

have been "shaved" which is not the way things should be done...

Swing/IRS... shouldn't make any difference and I can't see any potential clearance problems

I have never attempted it, but here are plenty of people who have fitted discs on the rear with standard front discs and claimed good

bias/performance. I had to fit a bias valve to my front circuit when I fitted big vented four-wheel discs; the fronts locked up prematurelynn[ Editedon 3-8-2005 by VWCOOL ]

| Quote: |

shave some non-stressed part such as the bearing/seal retainer

That is how I did mine-machined the bearing carrier instead of the caliper bracket.

| Quote: |

| Quote: |

vwcool

not so sure about street or race anymore.its my daily driver, but with 6point cage, harness',and a berg 1776, so its gonna get hammered regularly for

sure. like everyone i have a spare pan bj/irs, but i'm due for brake refurb on the rear now so with the rotors/drive hubs in porsche pattern sitting

at a mates house, its just the direction it headed.sounds like i'm doing a bit of pioneering, so may as well do a lil' thread with a few pics and

some feed back on how it turns out.i've seen nbturbo conversion and jak did one, but i cant get the pics off jaks- are there any other detailed

threads my search is not picking up?nn[ Edited on 5-8-2005 by dumone ]

Unless you have a trailer, tow car, CAMS licence and $1500 to spend every 'race' weekend on petrol, accomodation, entry, food, travelling around the

state, etc etc etc keep it street!

I stuck my head under a couple of cars today and I can't see any problems with fitting a swinger... Fit the new brakes now and transfer to your new

pan later. Easy!

Search "VWCOOL" and "big brakes" for some pics of rear EA conversion on IRS. There are shots of front AND backside of rear brakes... it may help

you

In my experience, it might be smart to attempt one side at a time.. that way it's only half the work to reassemble if you discover a clearance

problem :thumbnn[ Edited on 6-8-2005 by VWCOOL ]

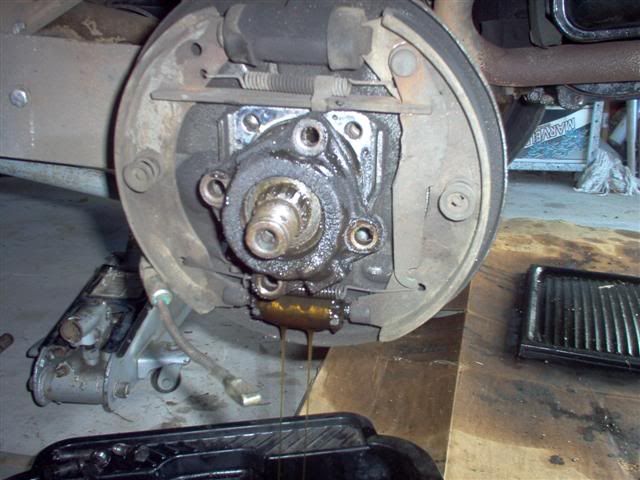

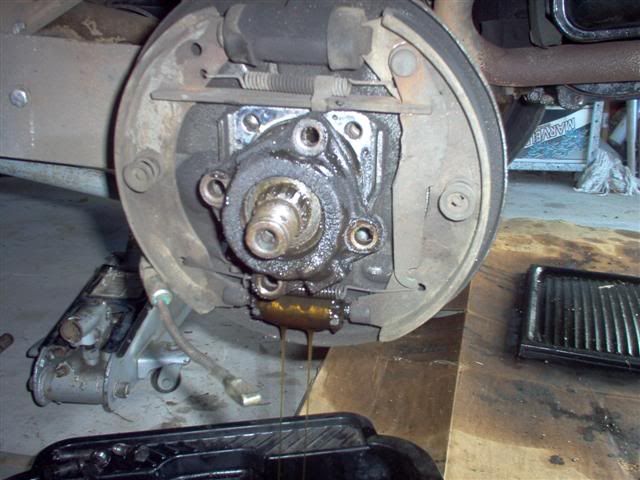

A couple of people have asked about my EA rear disc progress through u2u, so i'm putting up these pics for them.

As discussed in some previous posts, some of this is not strictly legal for street cars, but hey these pics don't show any car within cooooeee and i

will point out as much I can in that reguard.

heres the whole kit. too embarrased to say how much the new calipers cost me, but i have since found a place that does a pair of reco calipers for

$200 and hoses for $75 a pair, rotors with a set of pads for $110 a pair- these prices are as cheap as you will find! the brackets i got from

"segull"- ford holes welded, machined out in the center to fit the V.W rear bearing housing, shaved on the front and rear faces to the same

thickness as a V.W backing plate and finally redrilled (4 holes) to fit the rear bearing cover----thanx neil, they look great!!!

now shaving the plates (1mm each side) is frowned upon by some, but others talk of rotational forces rather than side loads and in that reguard, the

calipers actualy float side ways through the use of bushes where they bolt to the backing plates......hmmmm... the other option here is to machine the

actual bearing cap by the difference in thickness of the EA backing plate over the V.W ( about 2mm)

pic of the machined drive flanges (late type one or type 3 or some say cut down T1 drums??)

Yes mine are redrilled for porsche pattern THATS NAUGHTY! Ultimately you would seek new blank ones from a reputable dealer and drill and tap them or

use studs with nuts!!! some say that redrilling is legal IF you use studs others disagree with this theory saying never ever drill I DON'T KNOW! do

your research.

anyways, you can see the outer diameter needs to be taken down to fit inside of the ford rotor and the lip on the face of the drive flange also needs

reducing to fit the center of the ford rotor (shiny area) people like Vintage VW or V-force would do this for you on the blanks

[ Edited on 14-11-05 by dumone ]

this is why you have to machine down the outside diameter of the vw flange- so it fits snuggly into the EA rotor!

ohhh the nasty side of redrilling a V.W drive flange! clearly showing how the factory only reinforced where the original four studs are located and

consequently allowing a decent number of threads to hold your wheel bolts in!!! when you redrill the thickness is just no longer where you need it and

you only end up with about 3 or 4 threads on most of your wheel bolts.

IF you score blanks they should have a uniform thickness across the backside- as thick as where the vw one is reinforced- much better!!and highly

recommended for legalities.

why so many holes?? porsche pattern is the same PCD or pitch circle diameter as the standard 4 stud vw. meaning that both patterns are the same

distance from the center point of the rotors, for porsche (5 holes)you use one of the vw holes then the other four fit in between the original holes,

i'm so BAD!

PIC 2; if you choose to run studs, the locations of the heads of them will need to be spotfaced so they have a square face to sit flush against and

consequently straight and true on the threaded/wheel side so you can actually get the wheels on!!

PIC 3; heres what i intend to do with the ford holes- fill em in with counter sink screws!! better off over engineering? at least i should be sure the

rotation of the rotors/flanges won't be transfering to the wheelbolts, a close fit of the machining as well as five screws should do- i hope-don't

know about with an engineer.

[ Edited on 14-11-05 by dumone ]

PIC 1 this shows how the machining on the face of the vw drive flange now allows it to fit snuggly into the ford rotor---the hole in the center is way

smaller than that of a vw drum!!

PIC 2 there are lots of suitable wheel bolts out there, just got to know where to look! i needed longer ones with a slightly different shape under the

head to fit the porsche wheels.kombis are good for studs and also longer bolts from the late wasserboxers, audi have some but you cant go past

titanium porsche originals. counter sink screws come in many different sizes from your local engineers suppliers- high tensile please.

[ Edited on 14-11-05 by dumone ]

PIC 1 short axles mean late flanges don't allow the big axle nut to go on-solution- shorten the flange about 12mm from memory.

[ Edited on 14-11-05 by dumone ]

this is "jenny"s solution to the mis-match of the ratio between the vw hanbrake lever and ford calipers. from what i have searched out the handbrake

won't travel far enough to effectively operate the ea calipers. the cable also needs a spacer to effectively shorten it.as "vwcool" pointed out it

goes between the ford cable gudie/holder and sheath of your vw cable (between 10 and 45mm?)and of a diameter that allows the eye of the cable to be

inserted through!

the other pic of the funny brackets, they are used for allowing late vw calipers and DISC rotors on the front of a king/link pin suspension. two

versions are shown here with the most common being the straighter one. Y ou will also need special size bearings and machine out the bearing housing

to match on the discs- but not the stub axles- thank god!

[ Edited on 14-11-05 by dumone ]

[ Edited on 14-11-05 by dumone ]

I found you need to space out the handbrake cable bracket by about 10mm, too,and relocate the pivot point on teh handbrkae actuating lever (drill

another hole) to use the std Beetle handbrake cable - which is now retained via a bolt

[ Edited on 14-11-2005 by VWCOOL ]

looks good i say, but im planning on retaining the original stud pattern

five stud would be impossible.

i just had a quick fiddle and it looks like the 4 stud pattern wont go in between the ford holes either. the ford hole seems to foul one of thevw

holes each time. VWCOOL would be able to shed some light on this.

are blank ea discs available? if they are it would be s@#t easy. you would have to try DBA (disc brake aust.)they have a pretty comprehensive website.

or maybe studs and nuts would get you out of trouble, obviously i have only played with porsche pattern.

I bought new undrilled ED rotors when I did mine in 5x130 pattern.I machined the back of the VW hub and used Ford wheel studs pressed in from the

back.There is a huge range of Ford studs available in different lengths.

[ Edited on 14-11-2005 by nbturbo ]

| Quote: |

Just found this post

to clear the air , I have been doing the ford ea backing plates for 4 years .

I have supplied these to off road race cars and to date have not had one call to say they failed .

I must say the vw stud taped into the drive flange I do not like , even in a stock vw of any type .

It would be best to drill and press in ford studs from the rear then get custome made nuts if need be .

I have seen the vw bolt come out of the drive hub due the guy had the bolts

chrome plated

NBturbo , I have very good contacts with in the braking industry , however I can not for the life of me get hold of blank disks

I when down the V Force path and purchased the blank hub / disk .This is a quality product that works .

Just a quick one to you guys I been playing with ford brake pads & found a pad called GREEN STUFF , these are very good if you have a 600kg missile

like I have in the shed , that requires good brakes .

cheers seagull

Can't work that out Neil-any brake place that sells DBA stuff should be able to get them.The day I went to ask here,he phoned up DBA while I was there and they told him they sell undrilled and I could have all the slots and holes drilled as well and still leave the mounting flange undrilled.

eb rear rotors from DBA are 111BU, undrilled

I think when I bought mine we put an EB rotor on the counter alongside my old ED one and there were some differences between the 2- but it was a while back now.

ok cheers for the part number > I am going to make a call & see if I can get them in Perth

still doing the mods to the disc carriers seagul?

yes mate ,on exchange > I ran out of all my stock over here .

seagull

I downloaded the pdf cataloge from DBA website

111A is for EA,EA series II 1988 - 12/89 (disc thickness 15 mm)

111B is for EA series II, EB, ED, XR6, XR8 1990 - 94 (disc thickness 13 mm)

This might clarify things a little.