Vw motor trolly?

eraser - July 14th, 2008 at 10:10 PM

Howdy all,

I have done the google thing and i was wondering where i might find a few of these parts that seem to be tricks of the trades.

I was looking at a few vids of dropping the motor out and i saw this pretty cool looking trolly that allowed the jack to sit in the middle of it so

when you drop the motor it lands on this little trolly with wheels.

Also wondering about a little device that fits on the clutch to stop the flywheel from spinning when your undooign the bolts, given i havent called

around the local distributors yet.

-M

Brad - July 14th, 2008 at 10:29 PM

the flywheel locks are availible in most VW shops for around $10

The trollies are usually home made and are simply 4 wheels on a steel frame. I had one with a ply top with carpet fitted that worked well.

Notch Nut - July 14th, 2008 at 10:46 PM

The best trolley to lower a vw motor on is the bottom frame of a shopping trolley.

Cut the basket part off and use the lower section. Because it is usually shaped in a U you can fit a jack under the engine and have the trolley frame

surrounding the jack ready to support the engine as you lower it from the engine bay.

Most supermarkets should have them available.

MickH - July 14th, 2008 at 10:48 PM

LOL

Notch Nut - July 14th, 2008 at 10:55 PM

| Quote: |

Originally

posted by MickH

LOL

|

larf all ya like!! I'm serious dude!!

Best to choose the ones that have had the 4wd treatment so as not to upset the multinational owners (BYO Hacksaw or pensioner to wheel it back home to avoid suspicion......)

(BYO Hacksaw or pensioner to wheel it back home to avoid suspicion......)

(Not speaking from experience or anything..............)

I wouldn't know of such things occuring....I am a good citizen

MickH - July 14th, 2008 at 11:17 PM

And for the record.."apparently" the ones from Coles are the best..

Matt Ryan - July 15th, 2008 at 09:29 AM

This Guy used to be on Egay all the time but now he's moved to Oztion. This tool works for locking flywheel & also to lock rear wheel hub when

undoing big axle nut.

http://www.oztion.com.au/buy/auction.aspx?itemid=4074929&d=&sort=0&pg=1&cat=242&view=List&f1=0&f2=&t

ype2=&type3=&type4=&type5=&s=&pcode=&dis=0&freepost=

He also does an axle nut removal tool, bench top engine stands, a plate that goes on top of your jack to spread the load on engine & a trolley as

you described. (if he hasn't got one listed at the moment, just e-mail him).

I don't know the guy in any way but I do have one of those plates for engine/jack & I'm happy with it.

Oh, and his tools are all galvanised, as far as I can tell, my jack plate is anyway.

Regards,

Matt.

ancientbugger - July 15th, 2008 at 04:39 PM

I can see a strange and sudden rise of trolleys going missing

68AutoBug - July 15th, 2008 at 05:16 PM

| Quote: |

Originally

posted by eraser

Howdy all,

I have done the google thing and i was wondering where i might find a few of these parts that seem to be tricks of the trades.

I was looking at a few vids of dropping the motor out and i saw this pretty cool looking trolly that allowed the jack to sit in the middle of it so

when you drop the motor it lands on this little trolly with wheels.

-M

|

I have used one of those galvanised VW engine trolleys and they make taking the engine out easy..

especially with a removeable rear valance..

Down and out... lol

the flywheel lock is also good for manual cars...

it won't work for autos flexplates

also, there is a valve spring tool... its great too..

lucky, My Son has all these...

Lee

eraser - July 15th, 2008 at 09:58 PM

| Quote: |

Originally

posted by 68AutoBug

I have used one of those galvanised VW engine trolleys and they make taking the engine out easy..

especially with a removeable rear valance..

Down and out... lol

the flywheel lock is also good for manual cars...

it won't work for autos flexplates

also, there is a valve spring tool... its great too..

lucky, My Son has all these...

Lee

|

yeah i was acutally wondering about the flexplate (and after seeing your photogalery im scared i might damage my flexplate :P)

Anything special i need to watch out for when dropping the auto stick shift motor out? e.g any mreo hoses (appart form the obvious hoses?

and tell me more about this valve spring tool.

Notch Nut - July 15th, 2008 at 10:41 PM

| Quote: |

Originally

posted by MickH

And for the record.."apparently" the ones from Coles are the best..

|

Try to find one of the "rare" Bi-lo trolleys, Coles won't be needing them anymore!!

h - July 15th, 2008 at 10:56 PM

| Quote: |

Originally

posted by Notch Nut

The best trolley to lower a vw motor on is the bottom frame of a shopping trolley.

Cut the basket part off and use the lower section. Because it is usually shaped in a U you can fit a jack under the engine and have the trolley frame

surrounding the jack ready to support the engine as you lower it from the engine bay.

Most supermarkets should have them available.

|

here here.. i have done the same trick.. available when you next shop!

Notch Nut - July 15th, 2008 at 11:11 PM

| Quote: |

Originally

posted by h

| Quote: | Originally

posted by Notch Nut

The best trolley to lower a vw motor on is the bottom frame of a shopping trolley.

Cut the basket part off and use the lower section. Because it is usually shaped in a U you can fit a jack under the engine and have the trolley frame

surrounding the jack ready to support the engine as you lower it from the engine bay.

Most supermarkets should have them available.

|

here here.. i have done the same trick.. available when you next shop!

|

This method was mentioned to me a few years back by a "respectable" gentleman from a VW club. Having worked in supermarkets for many years, I now

know why the older folk never return their trolleys and drive pristine VW's!

eraser - July 16th, 2008 at 10:10 PM

could someone post a pic of one of these elusive trolly dollys? One that they may of just seen roaming the streets? (the finished product of corse)

Matt Ryan - July 17th, 2008 at 10:32 AM

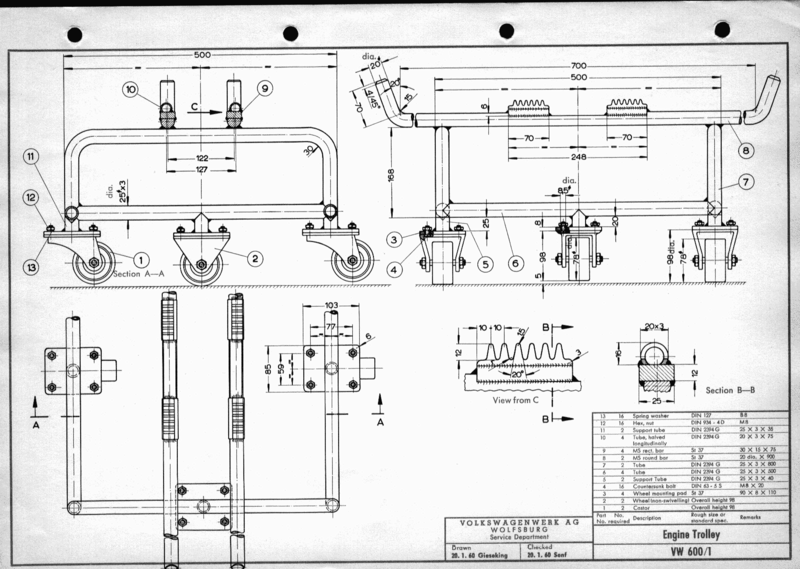

These pics are of plans for factory designed trolley for VW workshops.

Taken from: Obsolete Air-Cooled Documentation Project

http://oacdp.freeweb7.com

Regards,

Matt.

type3kid - July 17th, 2008 at 11:52 AM

Hey Notch Nut, i used to wotk in retail, dept manager at a major Supermarket.

i think i now know why we always seemed to have trolleys go missing.... hehehehehe.

(ps- carefactor is zero, good on you i say!! might as well get one back at them for screwing us where ever possible)

dangerous - July 17th, 2008 at 01:16 PM

make sure you get that 20 degree angle and 1.5 radii correct!

Pretty spiffy set up.

Just needs a mod to slide the trolley ack under it.

h - July 17th, 2008 at 01:37 PM

| Quote: |

Originally

posted by eraser

could someone post a pic of one of these elusive trolly dollys? One that they may of just seen roaming the streets? (the finished product of corse)

|

sorry no can do as mine is safely sleeping under a blanket in brisvegas town ATM..

h

Notch Nut - July 17th, 2008 at 03:45 PM

| Quote: |

Originally

posted by type3kid

Hey Notch Nut, i used to wotk in retail, dept manager at a major Supermarket.

i think i now know why we always seemed to have trolleys go missing.... hehehehehe.

(ps- carefactor is zero, good on you i say!! might as well get one back at them for screwing us where ever possible)

|

I've served 16 years of a life sentance in retail so far. Seen some interesting uses for trolleys in my time..

eraser - July 20th, 2008 at 04:39 PM

Someties you just gotta be lucky,

I was driving past coles/woolies and was actually saying to my partner "i need to find a trolly i can swipe for the beetle" which she rolled her

eyes to.

Anyway im driving arround behind the shopping center and i see something... i couldnt believe it...

Now is this all i wanted or am i needing to cut and weldo or something?

-Marc

Notch Nut - July 20th, 2008 at 07:14 PM

You will probably need to cut the top part of the frame where the basket was attached. Cut the un-needed bits off at the lower part of the frame so

it is flush. The U section (the frame part where the wheels are bolted onto) should be able to fit under the car so the engine can be lowered onto it

with the trolley jack.

Notch Nut - July 20th, 2008 at 07:15 PM

Don't worry if you stuff it up, as long as you have your reciept, they will be happy to oblige with an exchange or refund!!

eraser - July 20th, 2008 at 07:41 PM

I suppose i should ask, is there any part on the motor that shouldnt be sitting on the trolly as a load bearing point?

-Marc

h - July 20th, 2008 at 10:20 PM

yeah I put on a slab of wood for da donk 2 sit on...

h

humpty - August 17th, 2008 at 08:30 PM

I have a few I have made over the years, but the best one I have has 4x 130mm swivel casters which are bolted to a length of 40x40 angle iron that I

bent into a 'U' shape (I cut wedges out of the corners and welded them back at 90º).... It work perfectly.... The sump sits in the formed angle

iron frame and the trolley jack can be slipped under the engine with ease...

68AutoBug - August 17th, 2008 at 10:03 PM

here is the valve spring compressor

to take the valves out...

Excellent tool

My Son bought it from eBay a while back..

Lee

General_Failure - August 19th, 2008 at 07:58 PM

If anyone wants, I can take a pic of my lazy mans type4 engine/transmission trolley v.2.1

It has the integrated features of jacking and wheeling.

My second topend job was done with v.1.1 which was scissor jacks bolted to a big bit of ply with castors on it.

The third was done with v.1.0 initially (until it twisted and collapsed in a heap with the drivetrain on top of it. Ahem) and 1.1 with added

structural rigidity.

It is a three wheeled design. Two wheels on the engine end and one castor on the transmission end. Two scissor jacks support the moustache and one

cradles the transmission. They all have 'special adapters' on the top. Ie chunks of metal welded to them to extend and make them capable of stopping

the drivetrain from slipping off.

If it weren't for my idiocy it would have made reinstalling everything simple. But I forgot that the bellhousing mount needed to be aligned to make

everything fit.

Andy - August 19th, 2008 at 08:06 PM

I use a pallet trolley. Very easy to roll around, has a very low height when down and lifts 2-300mm.

I have found it very good, especially on the kombi to lower the motor and GB in one unit. You can pick them up cheap if you keep your eye's open.

eraser - September 8th, 2008 at 06:53 PM

General_Failure chuck a picture up always god to see everyones setups.

kevo - January 9th, 2009 at 02:34 PM

wen i used to work on the kombi, i was always pullin v8 in and out so me n a few mates just stole an ikea trolley and used that to roll engine under

the ass of the bus,

works pretty sweet.

(BYO Hacksaw or pensioner to wheel it back home to avoid suspicion......)

(BYO Hacksaw or pensioner to wheel it back home to avoid suspicion......)