"Bore For 94's"

dangerous - June 28th, 2009 at 05:55 AM

Here are some pics of how I do it.

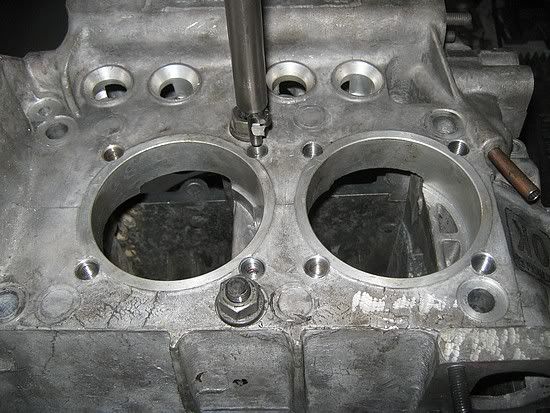

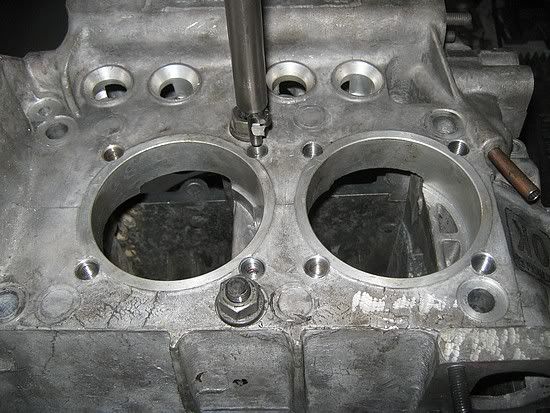

Some people just bore the hole for the barrel

right down to the bottom... with a sharp tool.

If it does not break through behind #3

it will most likely crack (from the sharp corner) at some point soon.

Some people do not "deck" the barrel face either.

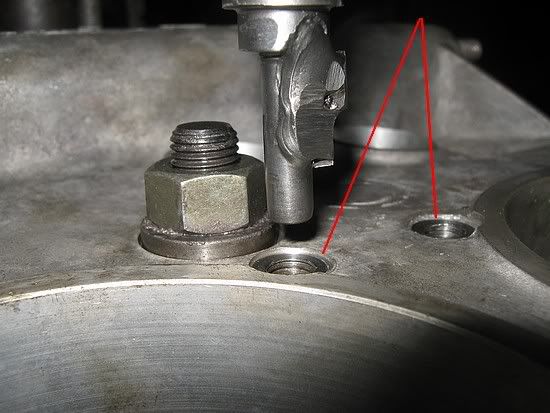

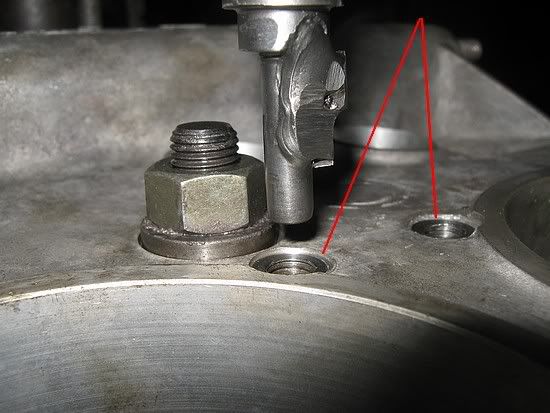

My first step is to spot face the case savers

so they will not lift the barrel at all, when the head nuts are tensioned.

I spot face them about .010" below the proposed final deck.

I then "deck the case" ...usually about .070", to make sure that ALL four will clean up

and have a nice flat surface for the barrel to sit on.

All surfaces must be at the same height from the crankshaft centreline.

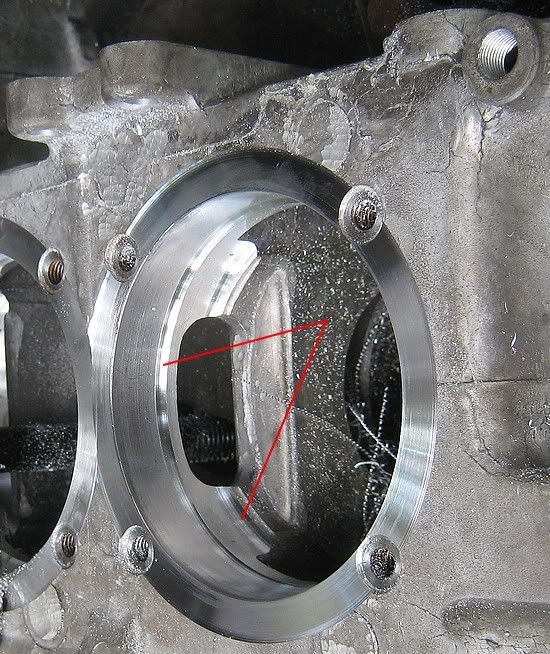

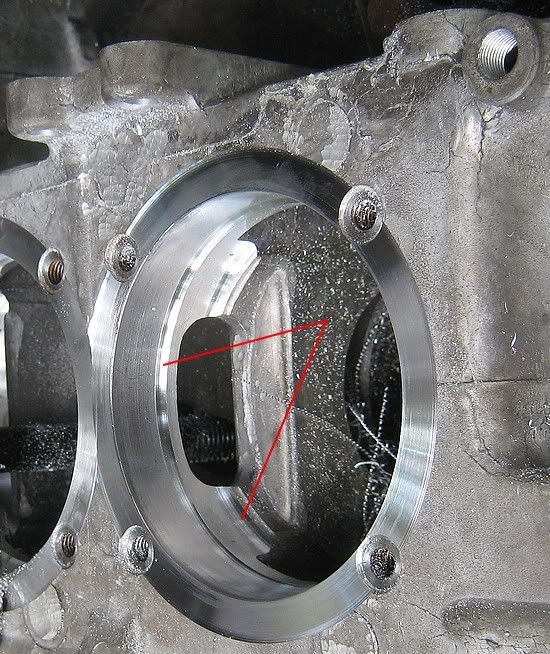

First step is for piston clearance,

and second step locates the barrel.

Before decking #3, I press in a sleeve

on top of the 'deep' top case saver,

to get a bit more support.

See the top stud hole closest to the FW.

By doing the bore and deck in one machine setting

you know that they are dead square.

dangerous - June 28th, 2009 at 06:03 AM

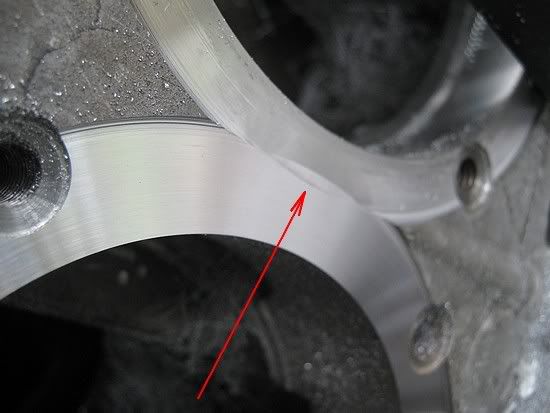

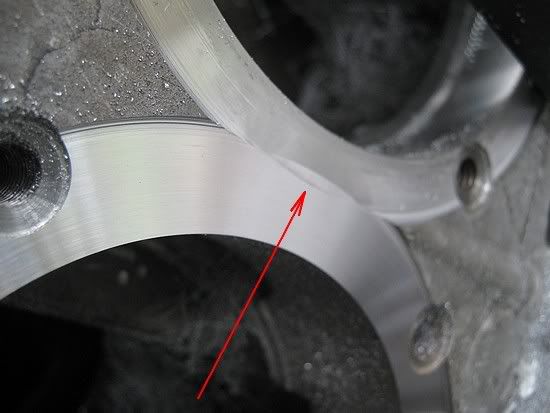

You will note that the decking process is only removing just enough material for the barrel to sit on.

Also note that I have used a nice large radius in the corners. (3mm radius)

Going to a larger bore,

is a good way to remove he sharp corners that are there from the VW factory.

Sharp corners are a good place for cracks to start,

so it is good to get rid of them.

Doing the job properly takes twice as long as boring the hole straight to the bottom,

with no steps , radii, or decking.

But it will give your engine a good base for a better lifespan

Brian - June 28th, 2009 at 07:35 AM

only a complete fuckwit would bore the case without a step

there is a few fuckwits out there

trickysimon - June 28th, 2009 at 10:16 AM

Always wanted to see how this was done

hellbugged - June 28th, 2009 at 10:58 AM

perfect and to the "nth degree" as always DB

bajachris88 - June 28th, 2009 at 10:33 PM

How much do u charge for this kinda service dangerous?

dangerous - June 29th, 2009 at 05:36 AM

I don't do it for anybody, it takes too long.

I am currently doing it on my big lathe,

so all the studs and oil suction pipe need to be removed.

I am saving up for a milling machine, may be then...prob about .....?

Stanley - June 29th, 2009 at 06:58 AM

wow...excellent stuff.

Once the mill arrives the sky is the limit

matberry - June 29th, 2009 at 09:24 AM

Dave well done as usual.

Not trying to steal any thunder, but if anyone wants this done, I (and probably Dave too) can organise it in Bris. Cost runs around $220- $270.

As a comparison, a less perfecto job may be around $120

dangerous - June 29th, 2009 at 05:55 PM

| Quote: |

Originally

posted by matberry

around $220- $270.

|

OK.

May be I WILL do some for people!

matberry - June 29th, 2009 at 10:45 PM

^^^^^About time Dave

Craig Torrens - June 30th, 2009 at 10:05 PM

Good work Dave...........unfortunately there is plenty of workshops out there just boring a hole straight through, some using a drill press!!!

dekkerboy - December 14th, 2009 at 02:11 PM

Mick motors charge $220 for the case to be milled for 94's

dangerous - June 22nd, 2010 at 08:42 AM

| Quote: |

Originally

posted by Craig Torrens

Good work Dave...........unfortunately there is plenty of workshops out there just boring a hole straight through, some using a drill press!!!

as a reference Stan Pobjoy charges $122 ($156 for an Aluminium case)for this work.....with the step bore, radius corners and the faces machined (and

yes its perfect!)

If anyone is getting this type of work done, then make sure you use a trained machinist that knows what they are doing.(and yes Dave is trained!)

|

I think these prices may have changed now.

See the PDF attachment that Craig posted, for the latest prices.

76bug - June 22nd, 2010 at 09:23 AM

wow its gone up $7 for a MAG case, its still half the price of some other places and top quality

dangerous - June 22nd, 2010 at 02:03 PM

| Quote: |

Originally

posted by 76bug

wow its gone up $7 for a MAG case, its still half the price of some other places and top quality

|

http://forums.aussieveedubbers.com/viewtopic.php?action=attachment&tid=84...

You need to add the bore AND deck price if you want a case bored for 94's.

129 + 89= $218

plus if you need case savers add that too, +$149.

dangerous - June 22nd, 2010 at 05:45 PM

Oh, thats a bargain then!

vw54 - March 7th, 2013 at 08:07 PM

HANG the price

Finding someone to do the job or is interetsed in it is far more important

Good machine shops are disappearing VERY fast

nils - March 8th, 2013 at 09:35 AM

thanks for the write up dave, always interested in this stuff

dangerous - March 9th, 2013 at 05:15 AM

This is nearly 4 years ago.

I have had my milling machine for a while now, so dont use the lathe any more.

Who ever people get to do their case machining,

ask them to use a radius tool (minimum 2 mm radii),

spot face the case savers just below the final deck,

and sleeve the #3 deep stud hole

to help support that thin web that is left when boring for 94's.

bushed - September 30th, 2016 at 09:12 AM

need to replace a broken head-stud 8mm ! recent Mexican case ..stud snapped on 1661 tp mtr

had a case saver in it ....hours to remove....anyone got larger savers ?

tried Micks just need 1 for ca 13mm dia saver and a 8 mm stud

happy to pay postage etc

0421286423

Bern...happy to come for a drive Sat?