Difficult Shifting with Aftermarket Gland Nut?!

dangerous - July 12th, 2012 at 05:38 AM

Some aftermarket gland nuts have their pilot bearing

installed too close to the outside.

This means that the input shaft can bind on it.

Thus it can never entirely disengage from the engine

when the clutch is operated.

Symptoms are difficult shifting,

and eventual deterioration of the synchros,

which have to work very hard to select the gears.

Even worse,

it can push the whole main shaft forward

and wear the nose cone,

then 4th gear can move out of gear

and machine itself into the intermediate housing.

Or even worse,

engine thrust bearing and shims can be over heated by the load,

eventually burning or spinning the bearing

due to the oil not being able to flow through to the thrust face.

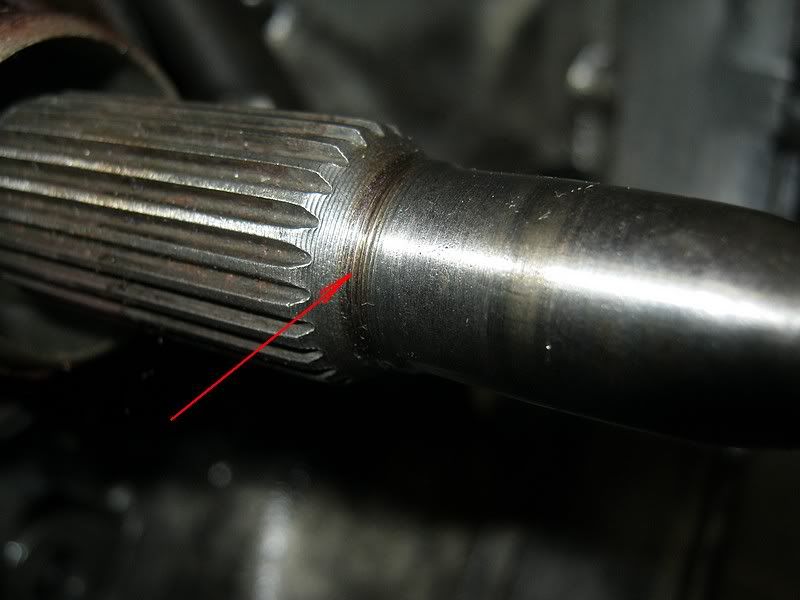

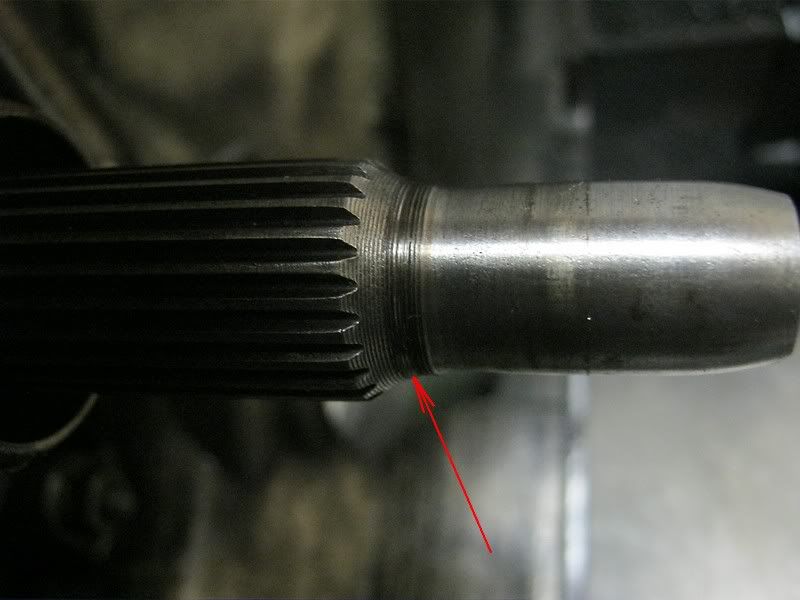

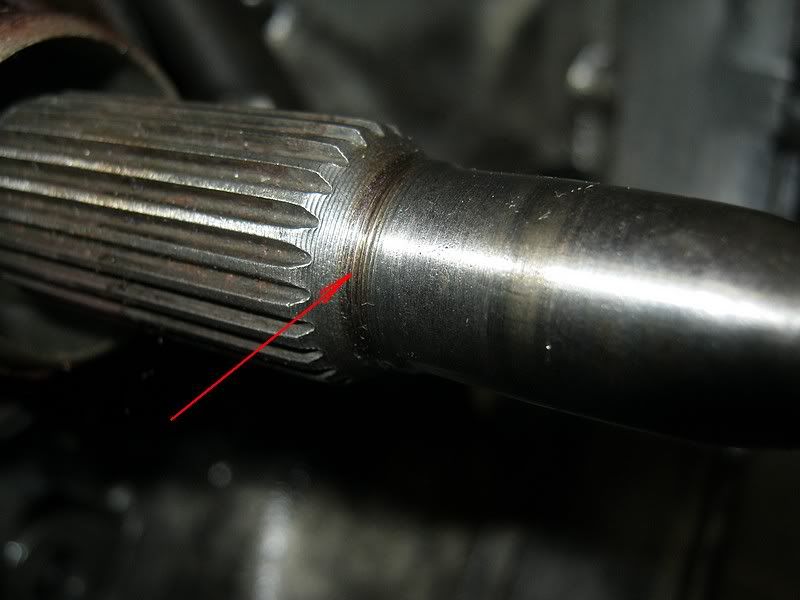

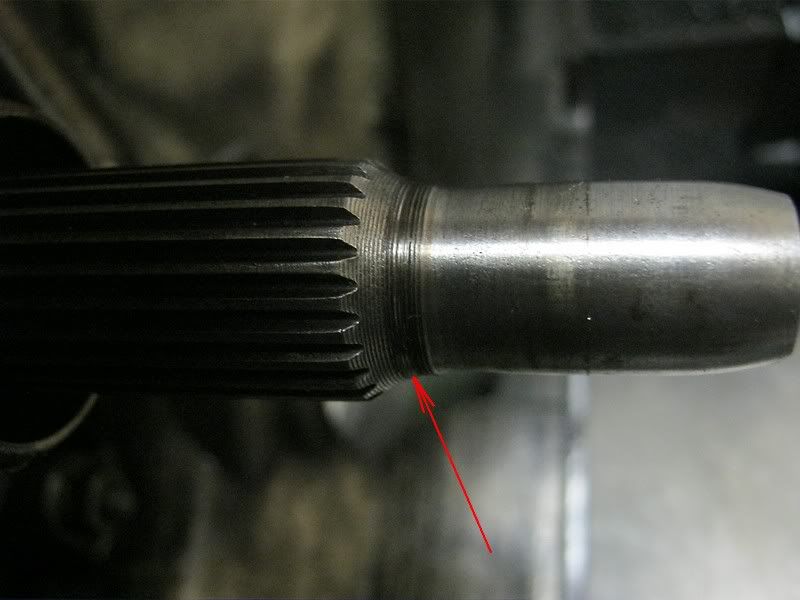

Here are the tell tale signs:

In this case,

the main shaft bearing was pushing hard onto the nose cone. Luckily a steel thrust plate in this instance,

protected the magnesium nose cone:

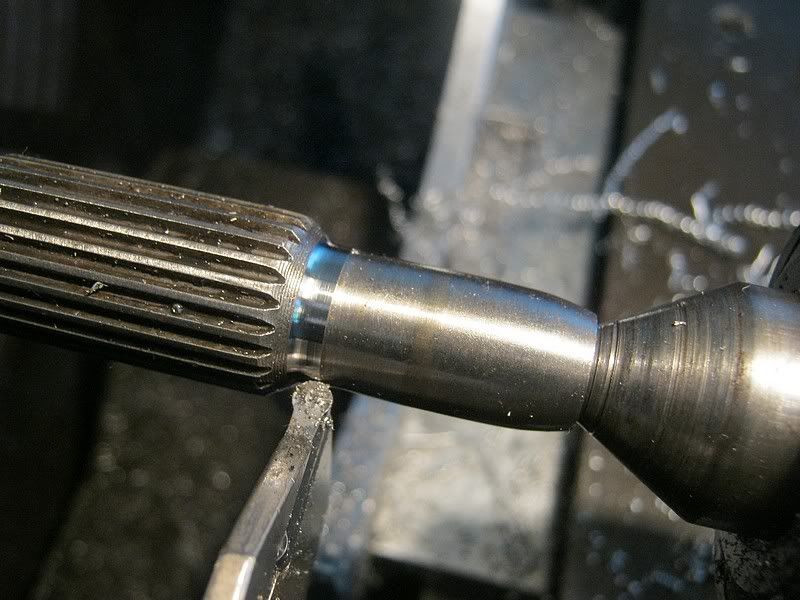

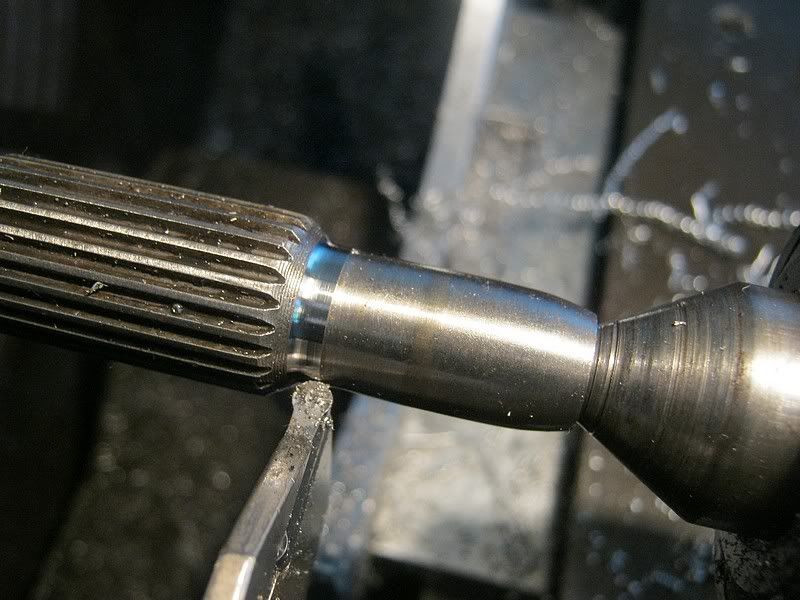

Simple solution is to replace the Gland nut with something better, or machine it so the bearing sits deeper, by about 3mm.

In this case the trans was due for disassembly and inspection, so the input shaft was machined to clear.

matberry - July 12th, 2012 at 08:54 AM

Yes Dave, as usual, you are ONTO IT  Thanks for your diagnosis and

repair. Dave called it before the trans and engine were even split from each other. Mileage in this case is 51 000 km before the issue raised it's

head in the form of 1st and 2nd synchro's giving up and making shifting difficult.

Thanks for your diagnosis and

repair. Dave called it before the trans and engine were even split from each other. Mileage in this case is 51 000 km before the issue raised it's

head in the form of 1st and 2nd synchro's giving up and making shifting difficult.

I do wonder though, the input shaft on type 2 tranny's is screwed into the mainshaft and locked into position by sliding the splined collar over the

top. Was the M6 thread close to being all the way home as this will effect the overall shaft length.

I will be using Gene Berg gland nuts from now on....they fit without issues. Shame the performance aftermarket manufacturers rarely seem to get it

right.

Ldog - July 12th, 2012 at 12:01 PM

Thanks for sharing I have Recently had this problem !!!

dangerous - July 13th, 2012 at 01:45 PM

| Quote: |

Originally

posted by matberry

.

I do wonder though, the input shaft on type 2 tranny's is screwed into the mainshaft and locked into position by sliding the splined collar over the

top. Was the M6 thread close to being all the way home as this will effect the overall shaft length.

|

For correct assembly,

the join where the M7 stud connects the shafts

is backed off a spline or two

to ensure the stud is unstressed.

This equates to less than 0.25mm.

Once it is fitted

the length can not change unless the stud strips

or is not installed correctly.

In this case everything was correct.

matberry - July 13th, 2012 at 02:04 PM

Cool, I figured it would have been but needed to ask. I too instal with the M7 (ok I got that one incorrect... ) backed a spline or two, but my point is it could effectively lengthen the shaft so does need attention with

this issue in mind.

) backed a spline or two, but my point is it could effectively lengthen the shaft so does need attention with

this issue in mind.

Thanks DB

66brm - July 19th, 2012 at 02:12 PM

Dave, can you tell us which non original glandnuts are causing the issue? I was going to use a CM glandnut in my current build but will toss it if its

even suspect.

Perhaps the first letter of the companies name will suffice

66brm

vassy66T1 - July 19th, 2012 at 05:29 PM

It was a Scat but when Matt took it off (the gland nut) for inspection, the spigot bearing could be pressed home another 3mm

Check this upon purchase of a gland nut and the issue may exist no longer ??

Interested to hear from DB if this was the same with the other one or more he is aware of.

dangerous - July 20th, 2012 at 05:14 AM

Hi Marcus,

in the other couple of instances I have seen

there was no room to press it in further.

The bearing had to be removed and the hole machined deeper,

or just a different brand fitted that was correct.

vassy66T1 - July 20th, 2012 at 08:17 AM

Thanks Dave

I was interested to hear what had happened in the other instances.

Gearbox is smooth as now

Thanks for your diagnosis and

repair. Dave called it before the trans and engine were even split from each other. Mileage in this case is 51 000 km before the issue raised it's

head in the form of 1st and 2nd synchro's giving up and making shifting difficult.

Thanks for your diagnosis and

repair. Dave called it before the trans and engine were even split from each other. Mileage in this case is 51 000 km before the issue raised it's

head in the form of 1st and 2nd synchro's giving up and making shifting difficult.

) backed a spline or two, but my point is it could effectively lengthen the shaft so does need attention with

this issue in mind.

) backed a spline or two, but my point is it could effectively lengthen the shaft so does need attention with

this issue in mind.