possible EJ25dohc rebuild ? Hairbrain or masterstroke ? What do you think?

Sunnyjim - September 19th, 2015 at 01:51 PM

A year or so ago I replaced the EJ25 dohc engine that was in my 76 Bus. It had several problems. Head gasket failure was not a surprise . AM auto guys

also said it has bottom end troubles (what exactly I dont know) but it blew blue smoke and shook and rattled a bit.

I am thinking of having a go at a rebuild myself. Whilst no mechanic I have learnt a real lot having completed my EJ 22 Into 71 kombi project.

My approach would be to pull it apart and see if it is worth rebuilding. what parts do I need to get inspected and measured ? Is it just the case

has anyone been down this road before?

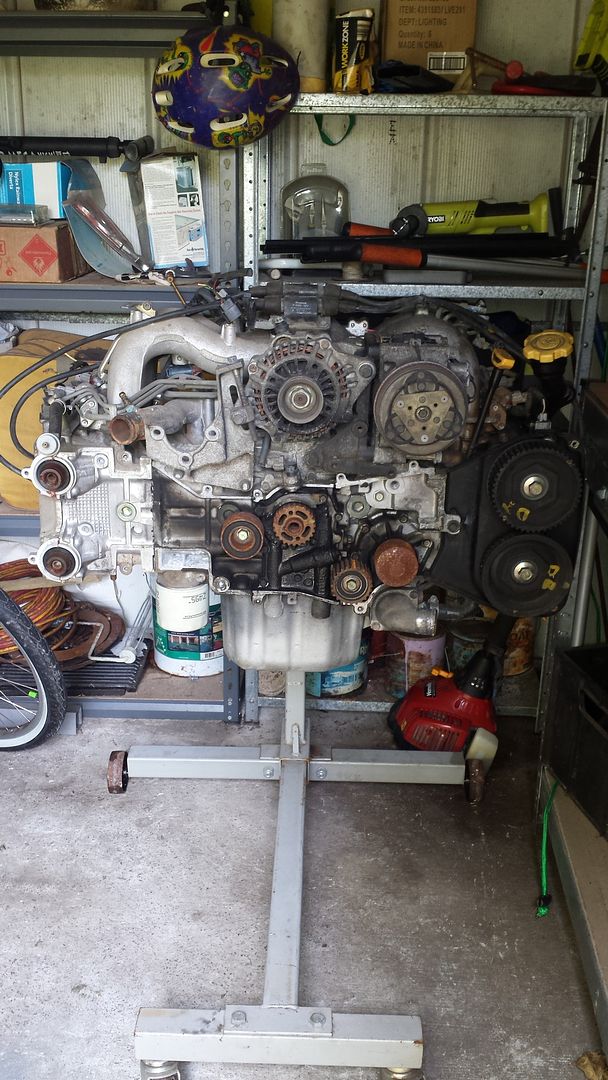

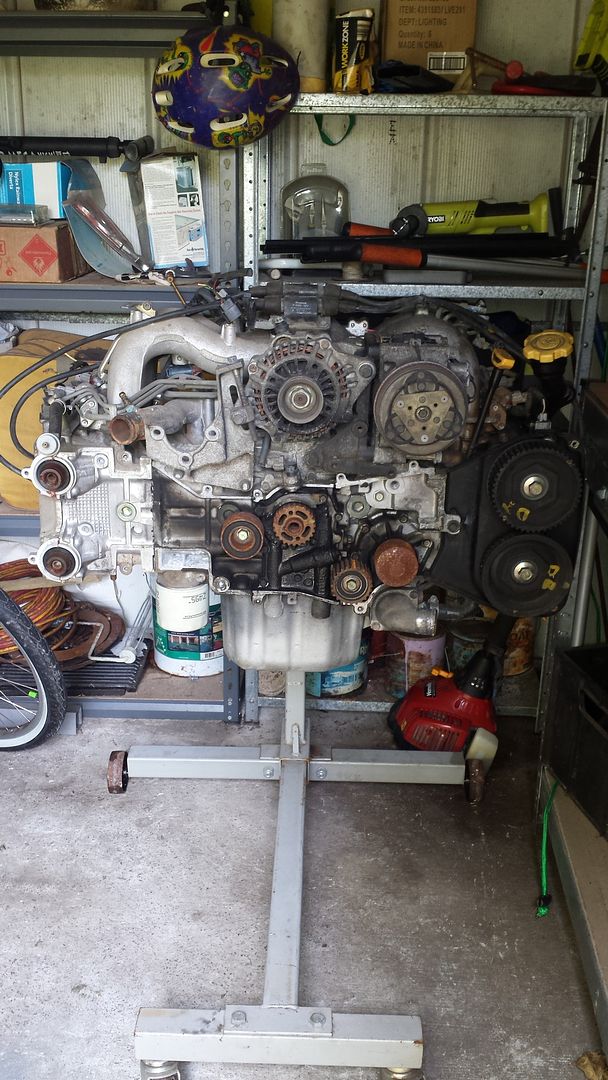

I have the motor on a stand all ready to be pulled apart.

Any advice is welcome

rocknrob - September 19th, 2015 at 08:10 PM

mate subaru engines muliply just the way vw,s did...if you need a good engine just find one on ebay...if you want to play with engines(like me) go

ahead and rebuild it but its not cheap...quite happy with my foresterGT in my kombi but rebuilding an EJ25 for later on...in other words i'm no help!

Sunnyjim - September 19th, 2015 at 08:38 PM

Rob

you are right about the multiplying !

I bought a good 2nd hand EJ25 dohc engine from a reputed source installed it and guess what ? this low Km Engine soon had a head gasket issue!

But of course as it took me 6 months to get it installed I have no recourse

So l thought why not give it ago myself !

1303Steve - September 20th, 2015 at 03:55 AM

Ive seen a few pulled apart, they dont look that hard

Sunnyjim - September 22nd, 2015 at 03:19 PM

STEVE

I will it a go but some good advice I got so far was NOT to buy any parts until I have it fully apart and know exactly what can be reused and what

needs to be rerplaced.

Sunnyjim - September 22nd, 2015 at 05:16 PM

good going so far

having the engine on a stand makes it easy to work with

the manifold and wiring haress came off easy via 8 bolts.

The po used to live on a farm so lots of dirt and stones sitting on top.

i see a lot of dried oil around the oil pump.

something else quite significant. the small pipe coming off the coolant was very rusty and just snapped when i touched it. i wonder if this

contributed to HG failure

rocknrob - September 22nd, 2015 at 08:02 PM

it all fits together Jim..not enough or the right coolant to prevent corrosion...galvanic action aluminium and steel will dissolve each other...if

they were running straight water in it look out for major corrosion! heads and block will need machining at the least i would say!

lou0060 - September 23rd, 2015 at 10:05 PM

hi Jim, good project. I'm a bit both ways, (carter shut up!) but when I blew my EJ20 up in the racecar, spun conrod bearing, I pulled it down and

found the crank journal damaged so ended up buying another 2nd hand engine for $400! has been pushed to the limit this year and not missing a beat.

Just lucky I guess...

The rebuild is pretty straight forward. If you google subi engine rebuild there is one particular guy who goes thru the rebuild on the floor of his

driveway! But he is great valve and worth watching.

And yes, don't buy anything till you have it apart and then see what you need and what your budget is. Ny the looks you'll need a full timing kit

with idlers adjuster etc a new crankcase seal, in fact a whole seal kit, maybe a new oil pump and water pump, some new water pipes and hoses, new head

bolts and a skim and maybe valves but they tend to be not too bad. How many KM the engine has done will play a part as well. And new bearing and

rings obviously..... it will all add up!

some info of what i did on my thread... good luck with it.

Sunnyjim - September 24th, 2015 at 08:32 AM

lou

Thanks for the comments. it all helps.

i have found a few good youtubes. a picture is worth thousand words.

i don't know how many kms on this old donk but as the conversion was done over 7 years ago could be up close to 300k.

i am wondering where to buy a good overhaul kit. This is the most complete one i have seen so far.

http://www.cleggengine.com/engine-rebuild-kits/subaru/subaru-2-5l-ej25-legacy...

the other thing i want to make sure i understand and get right is the actual gasket itself.

i have heard new ones are a real improvement on originals.

rocknrob - September 24th, 2015 at 07:24 PM

Jim get a head gasket with metal in it like 'cometic'...any turbo suby has metal gaskets..the others are cardboard i think!

lolight70 - September 24th, 2015 at 10:26 PM

Its a quad cam not a dual cam

afaik they only came out in oz in the early gen2 liberties and outbacks

(94-97),they did have head gasket issues

Sunnyjim - September 25th, 2015 at 07:35 PM

lowie you are right. It is a quad cam ej25 dohc 96 to 99 model.

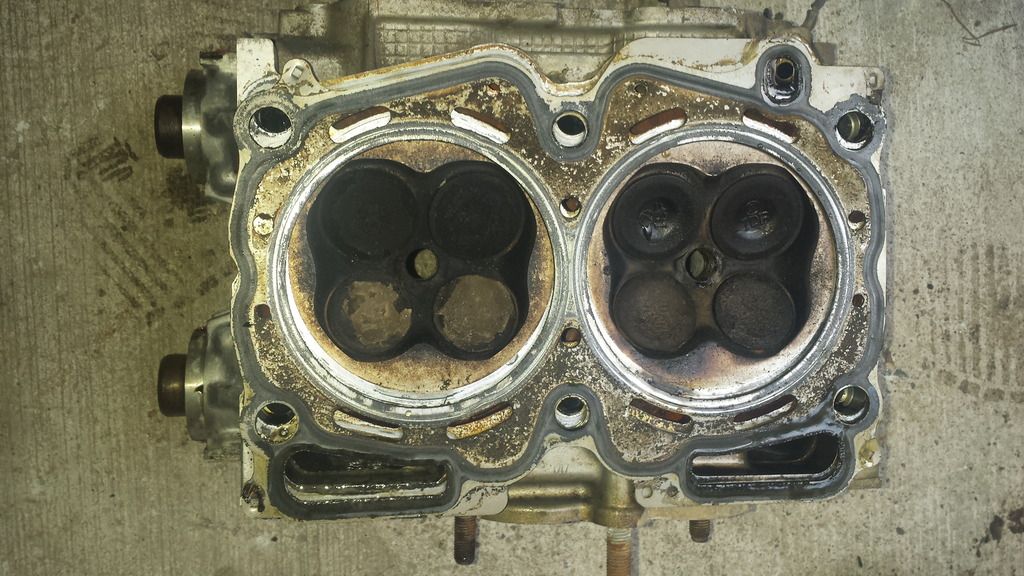

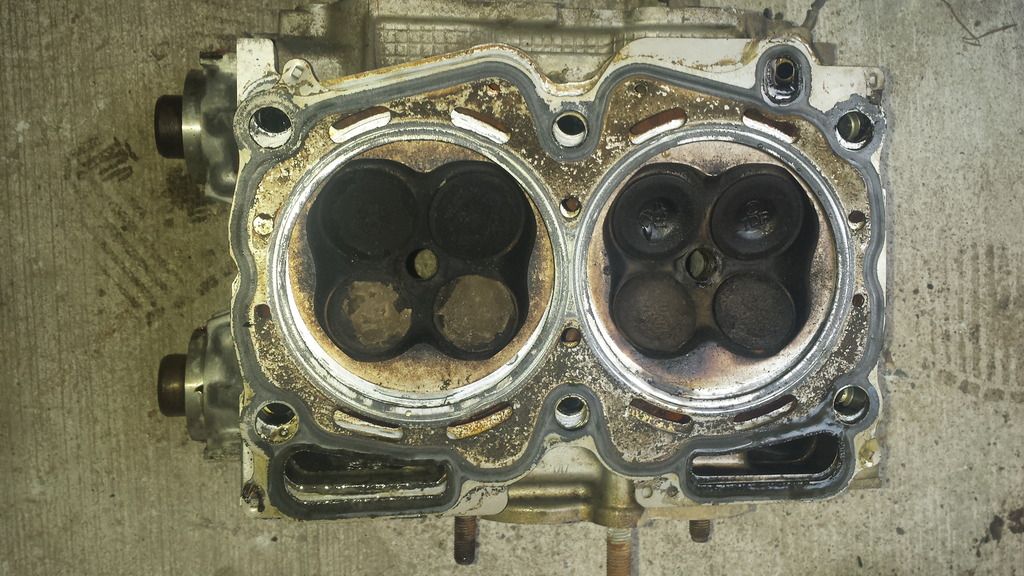

i noticed a real brown corrosion crud in the coolant channels.

Is that normal? or a sign of neglect?

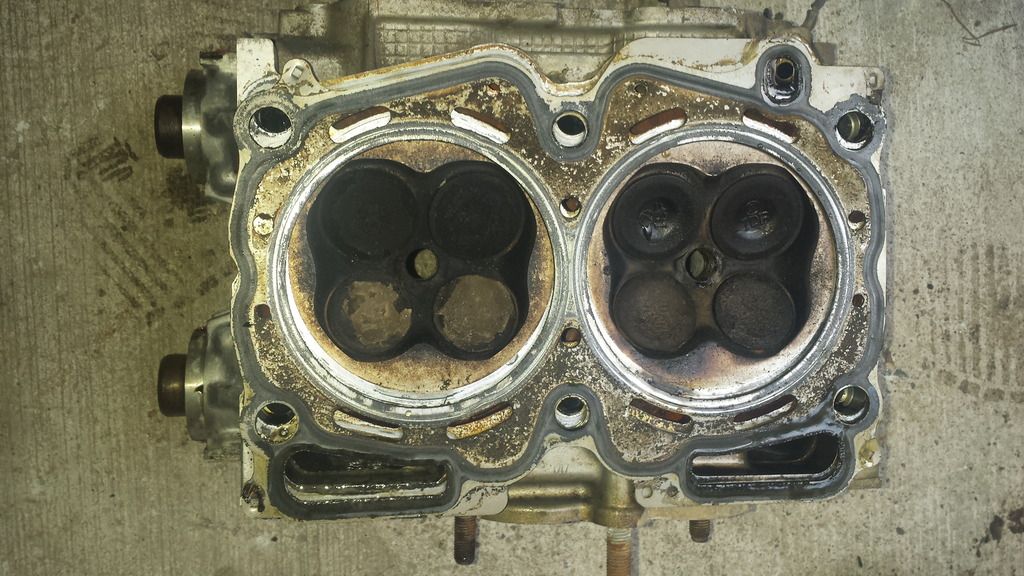

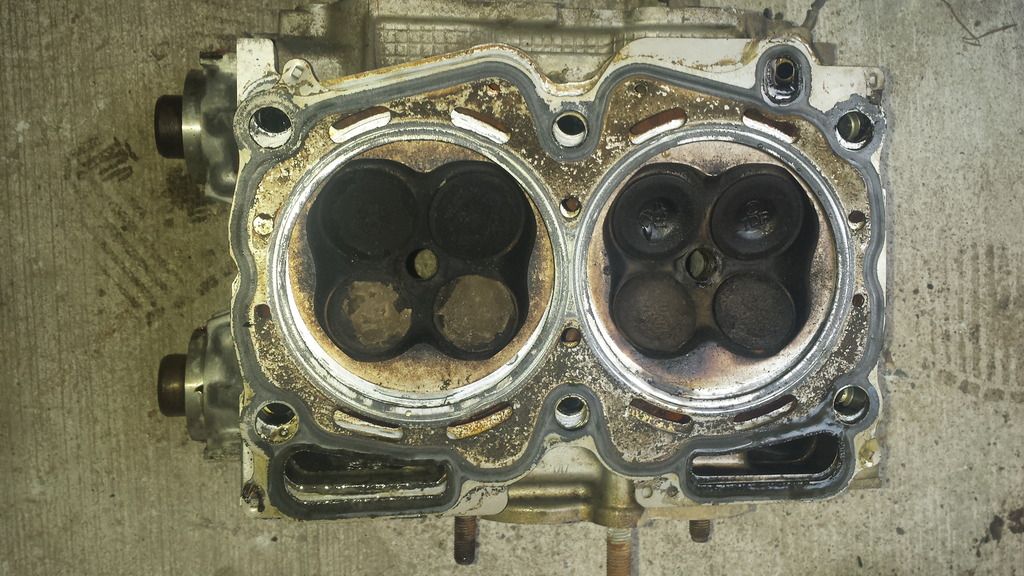

got one off the heads off as well. it already had the steel type gasket and i could not see any obvious problem

what about all this black stuff on the valves?

Subarugears - September 25th, 2015 at 10:13 PM

| Quote: |

Originally

posted by lolight70

Its a quad cam not a dual cam

afaik they only came out in oz in the early gen2 liberties and outbacks

(94-97),they did have head gasket issues

|

Yeah and that car that maybe a few people have heard of...a few million sold... the WRX

1303Steve - September 25th, 2015 at 10:57 PM

Be really careful with the cams on the left side of the motor or right side in VW, the wheels can spin easily and bend valves, I bought a special tool

lock them in place but my cam wheels have an Allen head bolt holding them on, maybe you can get on for your motor with a hex head

Sunnyjim - September 26th, 2015 at 10:24 AM

hi steve

not sure i fully understand.

i have taken the timing belt and rollers off . as this is a ej25 dohc a couple of the head bolts are under the camshaft. i removed the camshaft to

get to the head bolts. Then i reinstalled the camshaft just to keep it all together.

also does the corrosion look normal to you?

is the black carbon on the valves normal?

1303Steve - September 26th, 2015 at 10:29 AM

Just be careful which way you turn the cam wheels, turn them the wrong way and vales will hit.

Heads look fairly normal and the corrosion will clean up with a chemical bath

Sunnyjim - September 27th, 2015 at 07:17 AM

steve

ok thanks for the heads up

Sunnyjim - September 28th, 2015 at 06:55 PM

i had to take off cam gear to get to the head bolts

the head gaskets have been replaced already as these are the steel gaskets. i could not see much wrong other than a lot of carbon on the pistons

and valves but then again i don't have much experience looking at engine internals.

so soon i can take out pistons and crank then split the block

lou0060 - September 29th, 2015 at 07:58 PM

looking good so far.

there's a trick to getting those pistons out, not like a VW motor.

keep posting photos this should be a good thread.

Sunnyjim - September 29th, 2015 at 08:12 PM

lou

yep i will keep posting. i am a bit of a dummy but with feedback i learn quick😃

next challenge a couple of stubborn head bolts look corroded inside the water jackets

for the time being i have them soaking in wd40

chellejohno - September 30th, 2015 at 11:35 AM

Hey Paul,

Glad your doing this, I'll be watching with interest. I was thinking of doing the same, but didn't no whether it was viable or better off just

buying second handees whenever I wear one out.

Are you heading down to old bar this weekend

Cheers Johno

Sunnyjim - September 30th, 2015 at 04:06 PM

Johhno

no can't make old bar

the reason i am doing this build is that i really need to learn more

i bought a low km jap import engine. got it installed . Whilst i am convinced it is strong with n o smoke ir rattles it also has a head gasket

problem. i can't drive it further than about 20kms.

i had no recourse as it took me to long to get it instated

i just can't afford to pay someone so need to bite the bullet and learn myself.

You are welcome to venture over the south side and have a look.

Sunnyjim - October 1st, 2015 at 12:18 PM

Even though i suspect i should send the block away for some chemical clean in the future. I have spent a few hours and got the outside relatively

clean.

i am ready to separate the case. I have succeeded in loosening many of the case bolts but there are 6 inside the case water jackets(2 on the water

pump side, 4 on the other) that look to me severely corroded. they are deep down but the 12 point 12mm socket does not grip but spins. i have

scraped away a lot of rust on the bolts but i cannot see the 12 point edge that i would on normal new bolts. I assume all case bolts are the same

size but i can't see that confirmation anywhere. i will try to see if i can get 11mm on it but don't hold much hope.

so if we conclude 6 rusty head bolts what is the next step? it looks to me a tough job to drill and easyout them.

as usual good advice welcome.

Sunnyjim - October 11th, 2015 at 09:39 PM

So the situation is.... i can't split the ej25 case. seems to me the case bolts have been corroded and diameter reduced. The 12mm 12 star socket

spins around.

Any good ideas?

lou0060 - October 12th, 2015 at 07:08 PM

hi Jim, doesn't sound good.

From memory all the bolts are the same size.

you can buy a special bolt remover that should get them off. I'll have a look to see if I can find the brand name. They are USA made so good

quality.

would be a pity if this stopped you.

Sunnyjim - October 13th, 2015 at 07:59 AM

lou that would be much appreciated. i have also just been spraying them with wd40 in the hope that a few weeks of soaking might help once i find a

way to grip them.

Do you know if there is anything better than wd40?

1303Steve - October 13th, 2015 at 02:24 PM

Not sure if this will work or not, accurately find the centre of the bolt heads and drill the heads off and then deal with whats left over when the

case is apart

lou0060 - October 13th, 2015 at 08:26 PM

try this;

https://www.youtube.com/watch?v=5ZP05y32aJw

Irwin make them as well

WD40 is as good as anything else on the market. Problem here is that it needs to go all the way down to the threads which is difficult in this setup.

Sunnyjim - October 15th, 2015 at 06:19 AM

lou

yep got a set at bunnings.

still won't grip.

i realised the original case bolt is a 12 point but these c bolt extractors look like 6 point.

1303Steve - October 15th, 2015 at 07:26 AM

Try some Gibbs brand instead of WD40