2180cc build now Turbo

fish26 - March 11th, 2013 at 10:40 PM

I thought I would share this build with those who may be interested, its a mates engine we are building for a Manxter

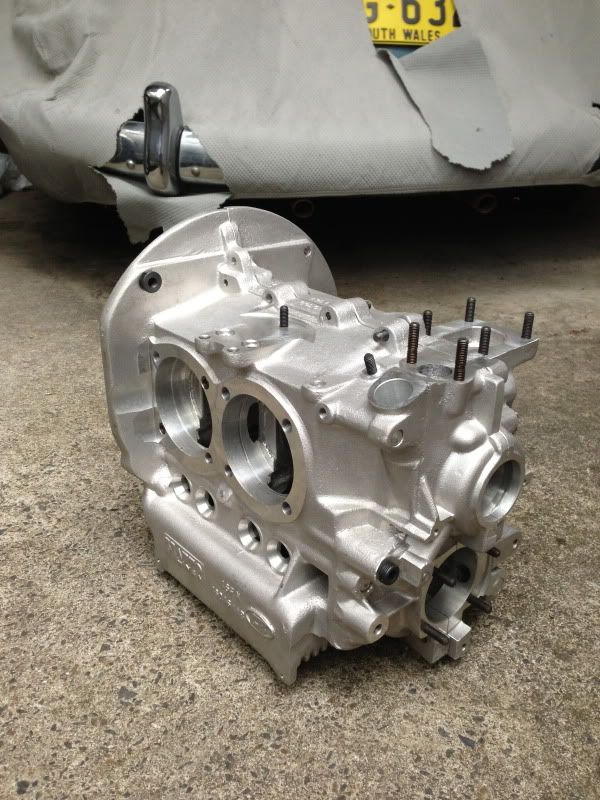

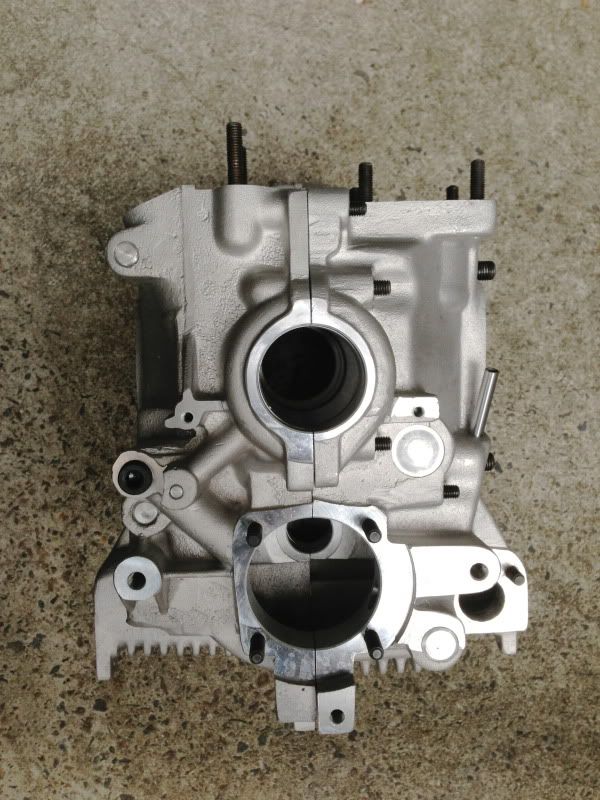

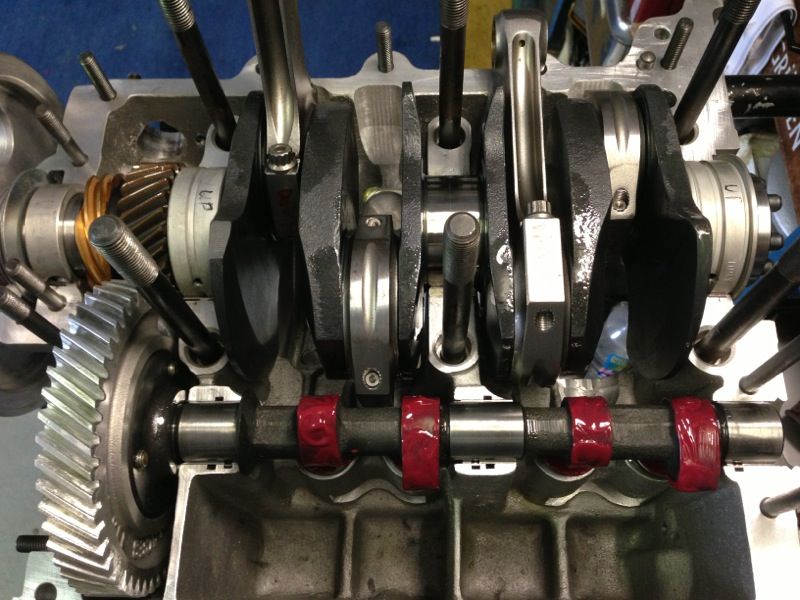

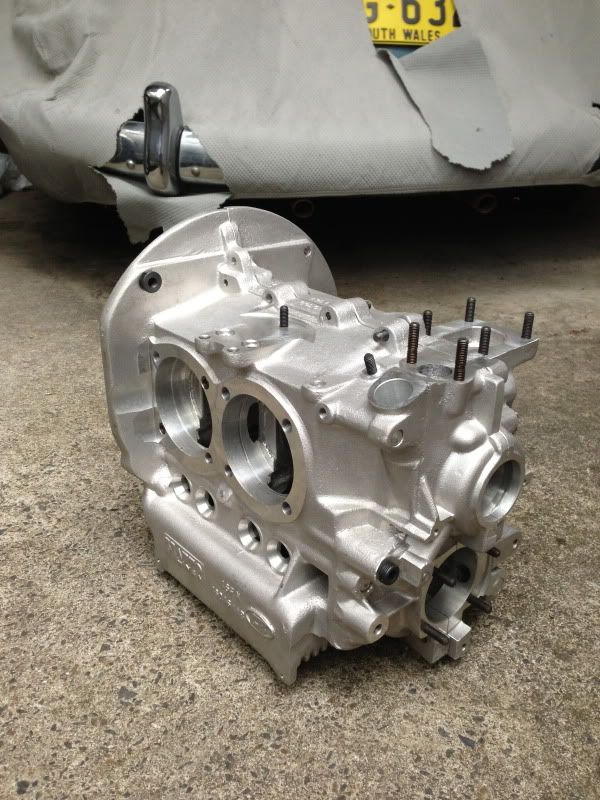

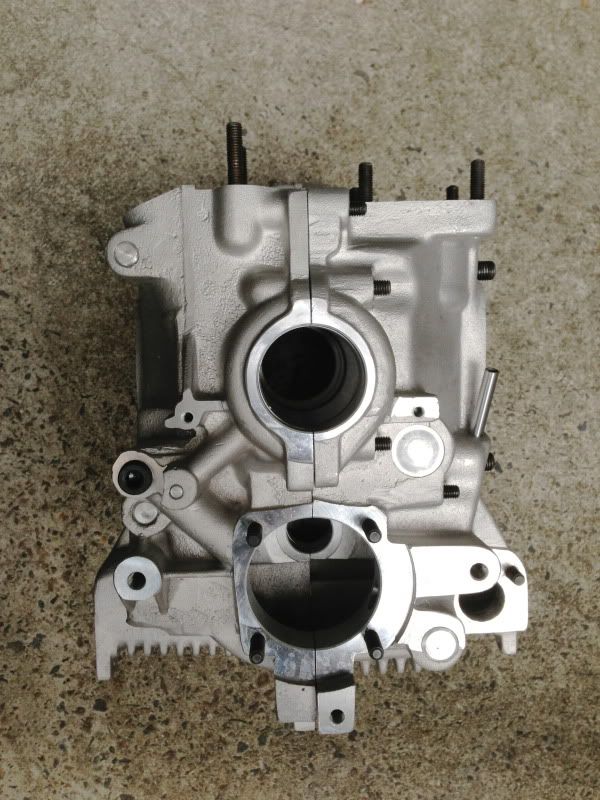

CB super race case 3.5mm deck

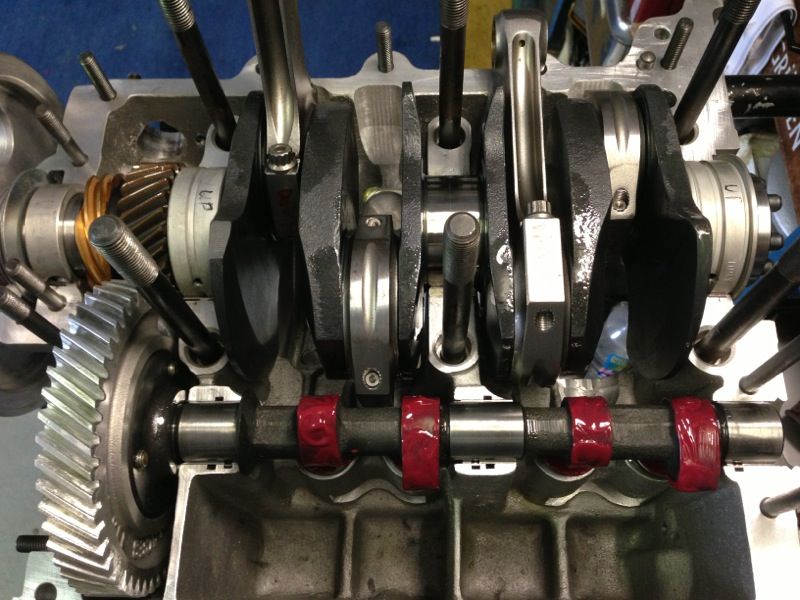

CB 82mm crank 8 dowel

CB 5.5 H beams

AA lightweight flywheel

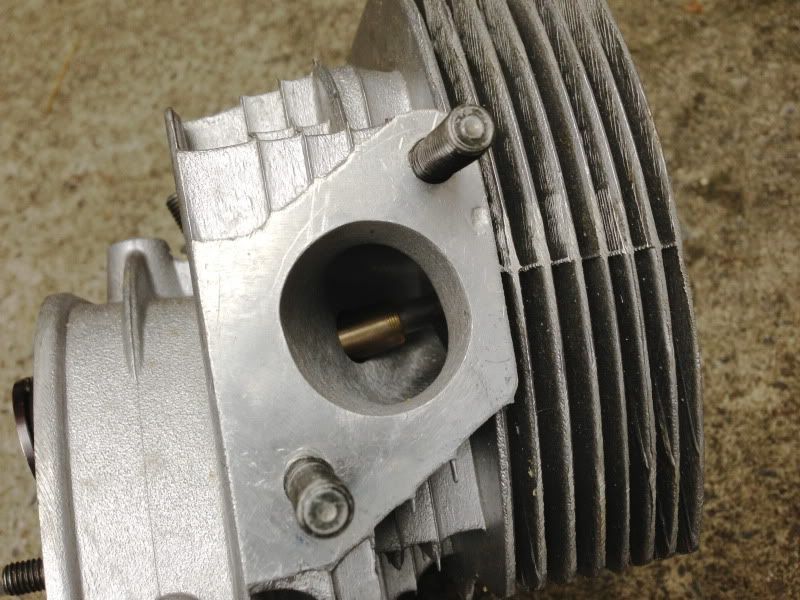

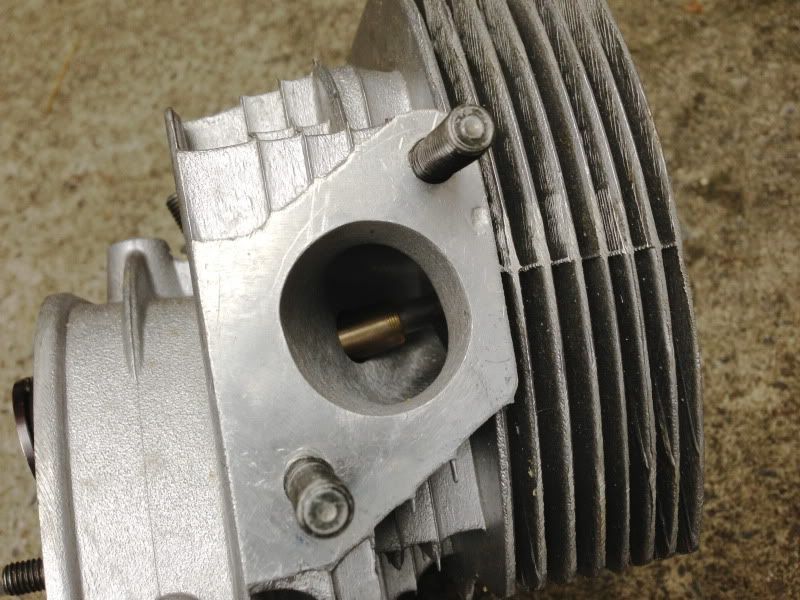

AA 92mm thick walls

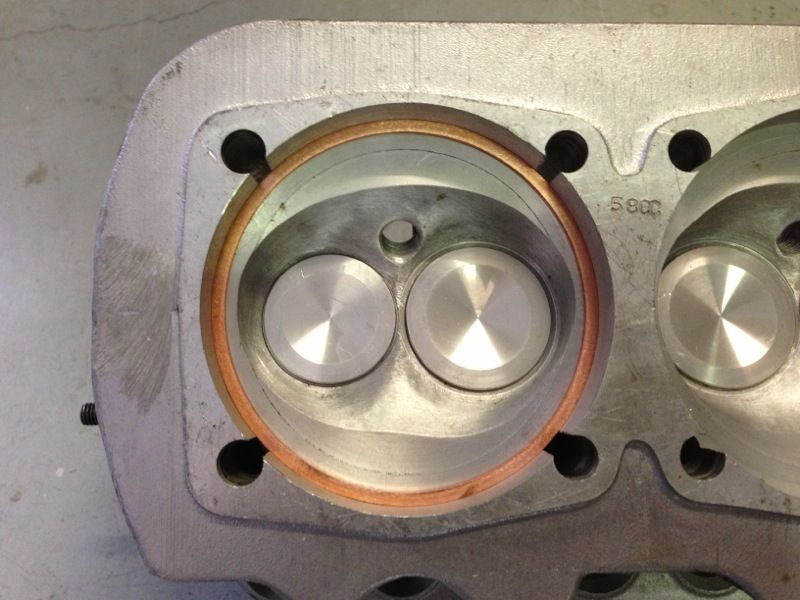

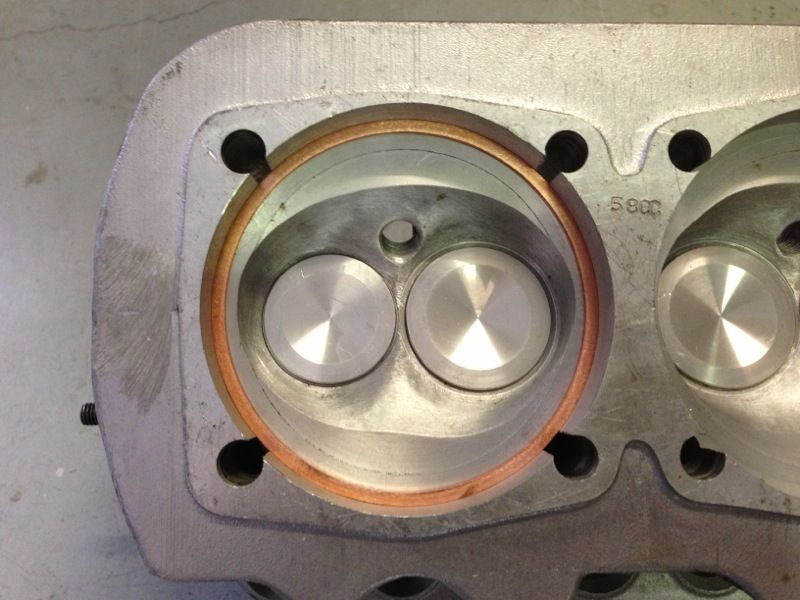

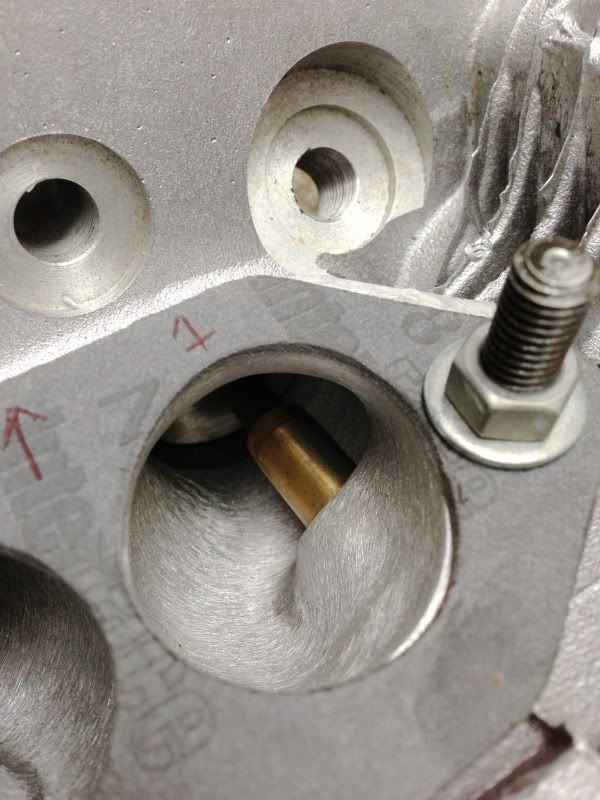

DRD hand oval ports 58cc 42x37 0.020" step

1.25 rockers

FK43 108 L/C straight up heli gears

CB Ultralight lifters

CroMo studs and push rods

CB Throttle bodies

Microtech ECU

Twin IHI VF14 turbochargers with custom intake and exhaust.

The mock assembly with above combination netted 0.003" deck, with 0.020" in the head I will be installing 0.060" copper head gasket from CB

CR is 8.57 static 6.58 dynamic with plans of running 8psi boost.

more coming soon.

cnfabo - March 11th, 2013 at 11:12 PM

Engine porn  can't wait for more. How are going to keep the front wheels

on the ground!!!!

can't wait for more. How are going to keep the front wheels

on the ground!!!!

matberry - March 12th, 2013 at 08:22 AM

Cool Fish, keep it up. Turbo 2180 should wake up a few Subi buggies.

LIFE IN THE LOW LANE - March 12th, 2013 at 07:22 PM

2180 with out a turbo would do that lol

Looks good mate!!

fish26 - March 12th, 2013 at 09:12 PM

thanks guys, we are hoping for 200 HP at the wheels on 8psi soft tune and 98 pump, ultimately reach 250 HP on E85 with bigger injectors and more

boost.

Once we get the engine installed Westi will be fabbing the intercoolers and relevant piping, I'd like to see twin coolers behind the Manxter side

pods.

grogy - March 12th, 2013 at 10:45 PM

no thrills for the cautious

westi - March 12th, 2013 at 11:06 PM

i got some fuel you should try.it's not meth.102oct.

fish26 - March 12th, 2013 at 11:29 PM

mate I'd love to, we can talk when I come past

LIFE IN THE LOW LANE - March 13th, 2013 at 02:39 PM

Troys old engine configuration made 248hp atw on 18psi from memory. 2332 with t3/4 turbo, welded volksy heads and unknown cam grind which he got with

engine originally from speedway car. Waste gate spring wouldn't hold any more boost and injectors were running 100% duty cycle so needed to be

bigger. They were modified rb26 dett skyline injectors. Now with comp eliminators, gt42r and methanol power should be a bit higher lol

fish26 - March 13th, 2013 at 08:56 PM

I would expect Troy's new engine configuration with that big ass turbo to easily make 350+

LIFE IN THE LOW LANE - March 13th, 2013 at 11:23 PM

We will see how it goes!! He plans to have it ready for Warwick. Mighten be painted and pretty but track ready.

dangerous - March 14th, 2013 at 11:42 AM

| Quote: |

Originally

posted by LIFE IN THE LOW LANE

Troys old engine configuration made 248hp atw on 18psi from memory. 2332 with t3/4 turbo, welded volksy heads and unknown cam grind which he got with

engine originally from speedway car. Waste gate spring wouldn't hold any more boost and injectors were running 100% duty cycle so needed to be

bigger. They were modified rb26 dett skyline injectors. Now with comp eliminators, gt42r and methanol power should be a bit higher lol

|

Even your memory talks things up!

Better check those numbers before using your memory.

With troy's head flow it would need over 30-intercooled-psi to make 350 at the wheels.

300 is a fair start position if he can keep the flywheel on it.

fish26 - March 14th, 2013 at 06:32 PM

lol i think we all exaggerate ever so slightly in the hope of getting there in the end

LIFE IN THE LOW LANE - March 14th, 2013 at 06:58 PM

| Quote: |

Originally

posted by dangerous

| Quote: | Originally

posted by LIFE IN THE LOW LANE

Troys old engine configuration made 248hp atw on 18psi from memory. 2332 with t3/4 turbo, welded volksy heads and unknown cam grind which he got with

engine originally from speedway car. Waste gate spring wouldn't hold any more boost and injectors were running 100% duty cycle so needed to be

bigger. They were modified rb26 dett skyline injectors. Now with comp eliminators, gt42r and methanol power should be a bit higher lol

|

Even your memory talks things up!

Better check those numbers before using your memory.

With troy's head flow it would need over 30-intercooled-psi to make 350 at the wheels.

300 is a fair start position if he can keep the flywheel on it.

|

I said it made 248hp atw not 350 dude. Thats the figures that troy has told me so im guessing he would know lol. could be telling porkies hahaha.As

for new combo who knows what it will do? But it definately has to make more than original set up wouldn't you think Dave? Bigger and better heads on

methanol with better pipes and manifolds it has to breathe better than what it did have..

dangerous - March 14th, 2013 at 08:34 PM

To clarify, my notes say Troys old engine(vw heads) made 227hp, and as much as 233 danger lean on 18psi.

a long way from 248.

My head flow comment WAS refering to his new heads/ engine.

Yes it should make more, but a wild guess is all you are making until it is running.

Sorry for the hijack, back to your regular programming....

vassy66T1 - March 14th, 2013 at 10:03 PM

Where's the like button??

hellbugged - March 14th, 2013 at 10:06 PM

| Quote: |

Originally

posted by vassy66T1

Where's the like button??

|

For the engine or the T.K.O ?

vassy66T1 - March 14th, 2013 at 10:20 PM

| Quote: |

Originally

posted by hellbugged

| Quote: | Originally

posted by vassy66T1

Where's the like button??

|

For the engine or the T.K.O ?

|

You"re onto it mate

fish26 - March 15th, 2013 at 03:23 PM

both I hope

vassy66T1 - March 15th, 2013 at 05:08 PM

Yeh both

typethreeking - March 23rd, 2013 at 11:15 AM

I love all this talk about my car and I haven't even said anything!!!!!

fish26 - March 23rd, 2013 at 04:49 PM

Yeah Troy, just get it on the dyno already.......

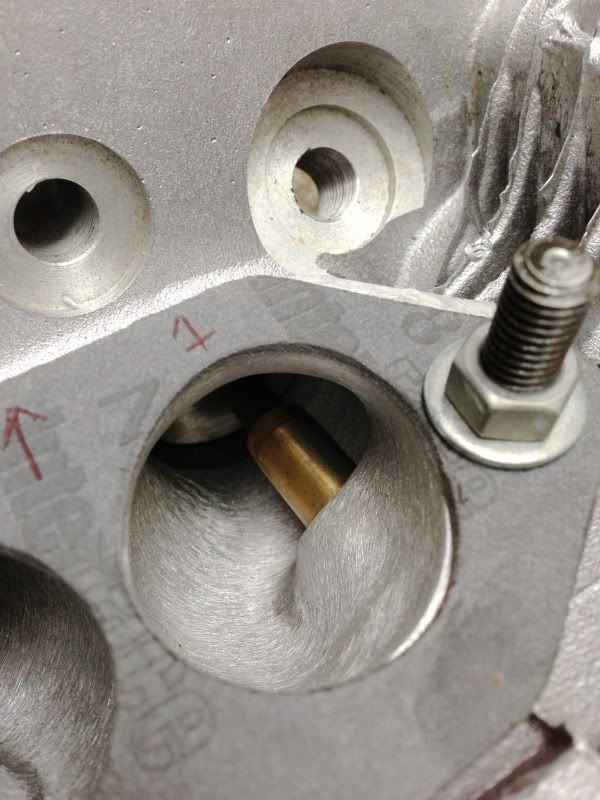

Another head to choose from after a slight massage

turboboy - March 25th, 2013 at 07:38 PM

Check around where the oil pickup tube goes to it the block.

Mine was cracked and required welding

fish26 - March 25th, 2013 at 10:52 PM

thanks mate, always best to double check twice...........not a lot of progress made hopefully will get the copper head gaskets and other goodies from

CB before the weekend.

Anyone else have issues with AA cromo flywheel mating to the CB crank?

debiasi4 - March 26th, 2013 at 06:05 AM

Those AA flywheels are not very good on the clutch surface. Found it was not very grippy surface and glazed up easily.even when resurfaced. I ended

up going back to lightened vw flywheels on anything that made decent power

Cheers Adam

matberry - March 26th, 2013 at 08:19 AM

^^ me too, the AA flywheels aren't a patch on old German VW. I know one of Australia's best clutch specialist that has offered to buy any old VW

flytwheels to use the clutch surface material in his custom alloy flywheels. It is in his opinion the best material he has ever experienced in his 40+

years of building clutches.

Recently I chucked a new replacement in the bin due to the flywheel mating surface being so poorly finished, it appeared it would have damaged the

crank quick smart.

German all the way for me too.

westi - March 27th, 2013 at 08:03 AM

not me ,but someone i know,didn't actually mate properly.

LIFE IN THE LOW LANE - March 28th, 2013 at 10:30 AM

I've run a lightened VW flywheel for years and never ever had a problem. Yanks are very anti lightening flywheels especially when it comes to

kombi's. my uncle has lightened a lot of VW flywheels over the years and he loves the quality of the steel they are made of.

fish26 - March 30th, 2013 at 09:32 PM

will sort out the flywheel issue later, I've just been messing around with setting rocker/valve geometry....I hate doing this,

find full lift 0.383

half it 0.1915

mark half lift

install adjustable pushrod and rockers

set rocker parallel to head, adjuster inline with pushrod, rocker tip 90* to valve stem

I'm close but not perfect, seems rocker stand needs a trim or thinner lash cap

Also got the 0.060" copper head gaskets checked out, now get this rocker geometry right.

Craig Torrens - March 30th, 2013 at 09:35 PM

its all the time consuming stuff....i hate it too !

can't wait for more. How are going to keep the front wheels

on the ground!!!!

can't wait for more. How are going to keep the front wheels

on the ground!!!!