What are you`re goals with you`re new engine? HP and ccm? Lift is very close to 20mm - big valve - high spring ratios - big results

I was a little concerned with the close proximity of the pushrod to the tube on my engine,

so I did some homework about pushrods.

Currently the engine has 3/8" straight 4130 pushrods, and after checking the lift with and without the heavy springs,

it seems there is enough flex to lose .035" of the lift.

So I have two problems: flex and interference. Problem is that to fix the flex problem will cause more interference.

The answer seems to be a tapered pushrod with better heat treatment.

This is nothing new, as I have used the Autocraft taper pushrods before

but not with these springs(620lbs) and rocker ratio(1.6).

Also the Autocraft pushrods are only 5/16" on each end,

and in the length I want, the don't begin their taper immediately.

And yes, you can buy some pushrods that will work, but you know me. I can make them exactly how I want them, and use the tips that I have already.

The material is 1/2" 4130 chrome moly tube with a .156" wall thickness...very strong.

Apparently, pushrod stiffness is more important than the weight gain. Some say that pushrod weight, and any weight on the lifter side of the valve

train, is not as important to valve control, as weight on the valve and retainer side of the rocker arm.

[ Edited on 31-3-2006 by dangerous ]

[ Edited on 20-11-2006 by dangerous ]

After hacksawing the material about 1mm too long, I can face it to length in the lathe, and drill the ends

to give 4 thou interference on the tips.

The rocker end will have a ball end for adjuster clearance, but the lifter end only needs a radius end.

The ball type end is an auto craft part, while the fat radius end is out of a very cheap 3/8" pushrod that I found at a swap meet.

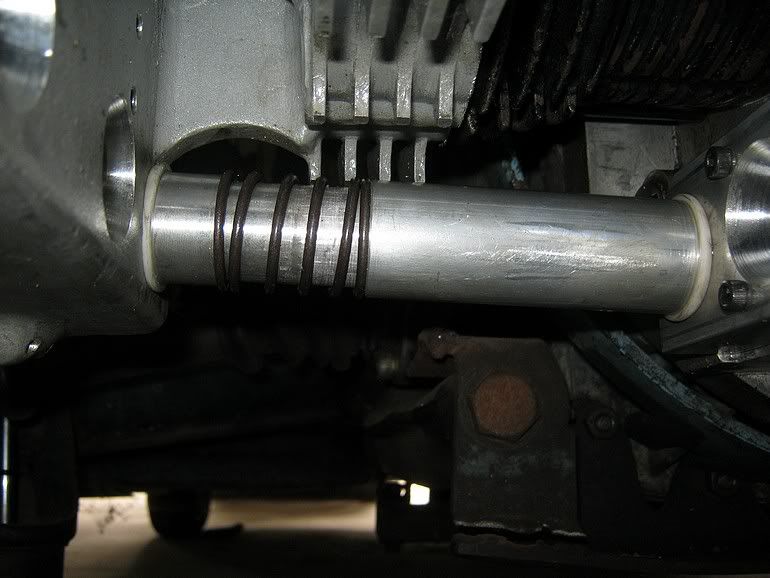

But before the ends are fitted I will taper turn the outside diameter to provide pushrod tube clearance.

In this case, the lathe tailstock was adjusted off centre by.100" to get the taper I need.

I have roughed it down to within 1/2mm of its finished size before heat treatment,

so that I can check the fit in the engine. I fitted the tips to this one, and checked the fit is OK.

So now I can send it to Rene in Adelaide (Volksy hell-guy) for hardening to increase the material's stiffness.

The finished size will be done when I get them back, and will be 8.5mm on the rocker end, 12mm in the middle,

and 10mm on the lifter end.

Rene will harden them to 42 rockwell C, which is about 180 000 psi tensile strength. He is the best for this stuff.

Only the tubing is heat treated, the tips are already hard, and will be fitted when the tubes come back.

How is this?

[ Edited on 27-1-2006 by dangerous ]

They are some nice pushrods!!

Would you consider making some for other people, and if so , how much$

The reality about a project like this is that it is only cost effective if you make them your self.

To be viable as a money maker you have to remember that the tubing is just under $200.

Then you have the cost of the ends(?).

Heat treatment I would guess at $100,

and of course labour to make them.

Suddenly you have a set of pushrods that cost about $700!

The best of the pushrods you can buy for Volksies, like Berg or Autocraft are less than half this.

Most engines can use the basic Scat or Berg 80000psi deals for under $150 (3/8" chrome moly).

BTW 1200's are cool. Mine ran 20.95 et @ 62mph.

[ Edited on 28-1-2006 by dangerous ]

Yes I know they would be expensive,like you said, the material is not cheap then heat treating and labour....it does add up to a lot.

But a set of Manton(?) tapered ones like the ones you have made would not be cheap either.

Your ones look a lot stronger than anything else on the market for volksies, and personaly I dont trust chinese quality "chrome-moly" that all the

other ones are made of.

Yes 1200's are cool!..........and slow too!

This one Simon!

Cheers Dave..... Thats some good looking work there... I can appreciate the effort your putting in here.... Awesome stuff!

| Quote: |

Nice,

Over here we`re buying HD ALU pushrods from either JPM or Skinne Racing. They weigh 65gr (with ends) and are tested with K800`s and "old school,

crazy high spring pressures"

The best thing about them apart from low weigh is of course that you do not need to adjust you valve lash every now and then and of course the

silence.

How much are they?

T54

Just so people are aware, this post was started in 2006.

My new pushrods will be a lot thicker than those because of the 1.7 rocker ratio and 1000lb springs.

Just did an initial check with light test springs and there is .762" lift

I think Aluminium pushrods are a great option for a lot of applications,

just not mine.

Dangerous;

What are you`re goals with you`re new engine? HP and ccm? Lift is very close to 20mm - big valve - high spring ratios - big results

Hi BeetleBug

engine is 2699cc with 82 stroke and 102.36mm bore.

Aiming for mid tens eventually.

Best so far weighing 805kg is 10.93@122.

using Pauter heads.

New heads are CD that I have been working on and off for 2 years

!000 lb springs !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! wow !!!!

Dave why so much if you are going to run titanium valves ? Mike

Hi Mike,

I dont think I need that much,

but even now with 620lbs and .690" there are small signs that i could do with a little more pressure.

When ordering my valves and springs,

Roger crawford said this is the way to go.

It is a sort of compounding issue actually.

When stepping up from the 1.6 to 1.7 rockers,

the extra spring required, is amplified back onto the pushrod,(1.7x),

and so this needs stiffer pushrods.

Stiffer pushrods mean heavier pushrods,

...which need more spring.

Hey Dave,

I know that everything you do is cutting edge and I really enjoy reading of your progress, you are a very open person and willing to share

your knowlege with us all , thanks . How much airflow will you gain by lifting more than 25% of the valve size or is it that you are trying to keep

it flowing at your best lift for a longer duration by over lifting the valve ? The reason I ask is that when I flowbenched my heads they did not gain

much airflow beyond 25% of the valve head size. I know your heads are WAY better than mine were and you know what and why you do everything. I just

like to learn, Mike

Hi Mike, most of the heads I have done keep flowing more air the higher you lift the valve.

It normally levels out around the .700 mark but still climbs a little.

This particular time I have changed the seat angle , which supposedly allows mor flow in the +.600 area,

so it will be interesting to see what the flow bench says.

Even if the flow levels out, there is still an advantage, because the valve will spend more time at the higher flow numbers.

Mind you, if the engine is too small, or can not see the RPM needed to make use of the additional air flow it may just lose performance.

The only head that I saw loose flow at higher lift was a Ford 351 cleavland.

but once the seat was sunk into the chamber so as to have it about .060" wide top 30 degree,

it made a night and day difference.

The flowbench I used was a Superflow 110 when I did my Superflow 48x40 heads, but I am getting older and more senile so I probably remember it wrong ,hhahahaha

New material has arrived!

just whack them straight in Dave  they'll fit perfect.

they'll fit perfect.

Holy cr@p... that's huge !!!

(and a little voice in the back of my mind goes "heh... that's what she said"...  )

)

Just got them back from hardening,(Thanks rene'!),

and fitted the tips and polished the outside.

Red arrow is 1/2" and yellow is 3/4".

How do you go with pushrod tube clearance with those? Looks like they would almost fill the tube restricting return oil flow.

Pushrod tubes are 32mm/27mm with 25 inside....heaps of room for drain back.

They look awesome.

Got 2 questions...

1. how much do they weigh compared to the usual hipo pushrod?

2. if they don't bend, what else will break?

| Quote: |

#2 - best answer ever

im looong overdue for a visit to yours db, have stuff sitting here waiting for a chance to get down there, free friday?