2442 progress

Dasdubber - May 31st, 2009 at 03:24 PM

Finally got to meet Marty Staggs today here in the outskirts of LA who is building my 2442 turbo/EFI engine.

Its been on the backburner for a while which was okay with me (to save some more $) whilst he got a few other engines finished (a few went to France,

others in the US). He is also trying to get his 3L Pauter twin turbo engine finalised for his Altered. So the progress will continue soon on mine.

Anyway, a few pics I took today with some specs mixed in.

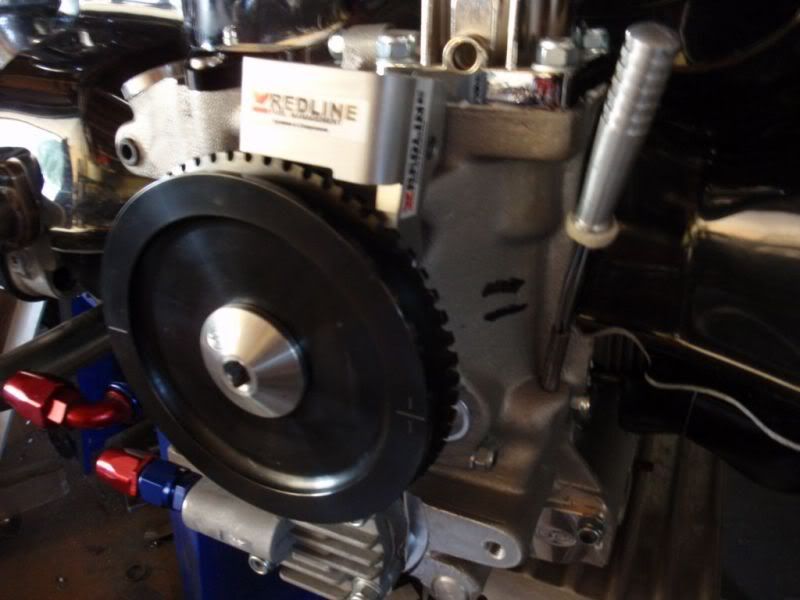

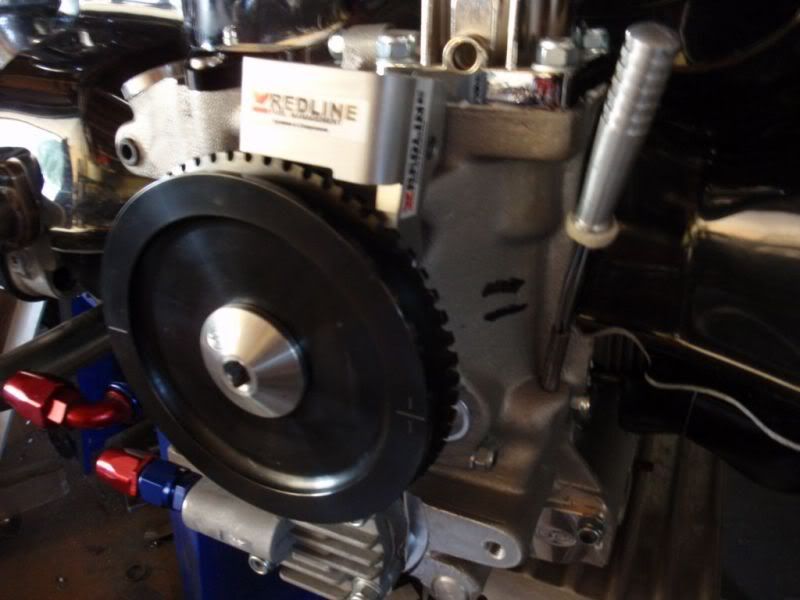

Flanged bugpack 88mm crank

Pauter 5.7 Chevy journal rods

94mm Wiseco pistons with Cima barrels (total seal second rings)

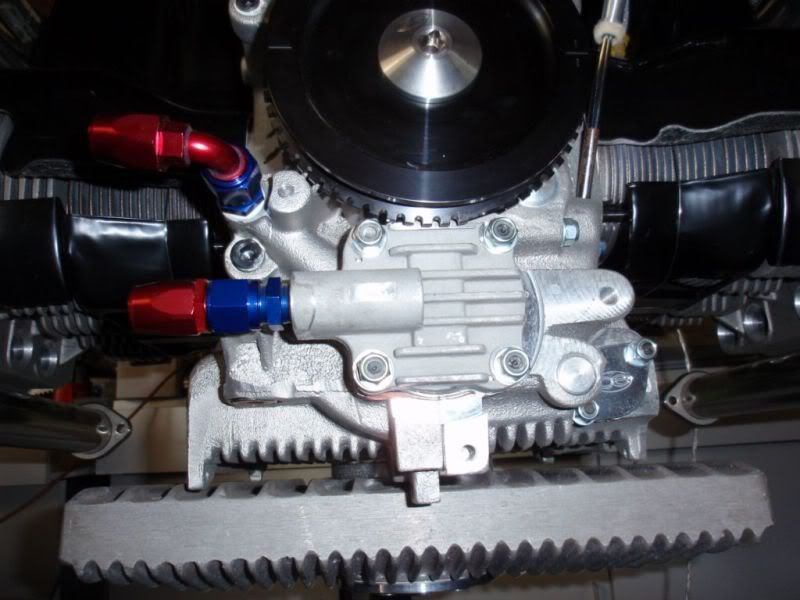

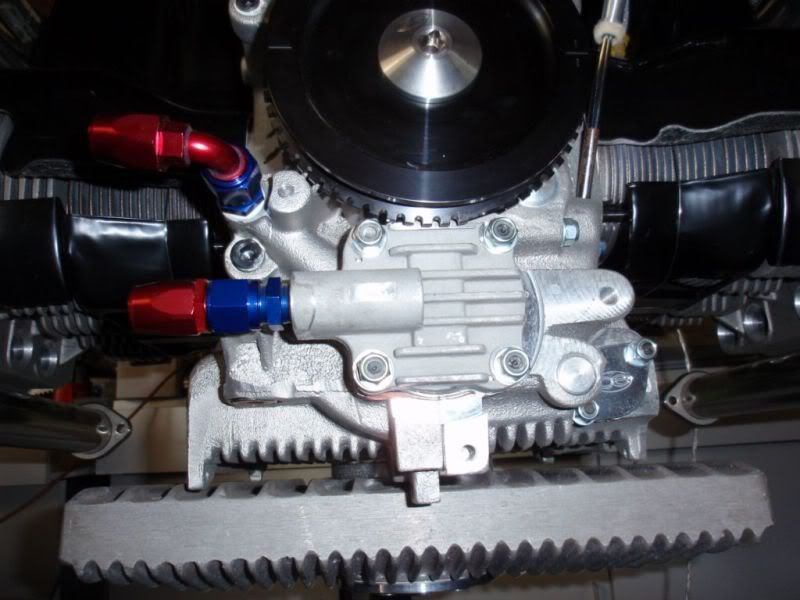

Modified Berg oil sump, CB raised roof case, Staggs turbo grind cam plus CE straight cut gears, DTM cooling shroud

Dasdubber - May 31st, 2009 at 03:31 PM

Top chrome pulley will be replaced with CE unit. Manton double taper pushrods will go in along with Jaycee pushrod tubes.

CB competition eliminator heads (44x40) with hand porting

Was hard to get non blurry pics of the exhaust ports - happy to share any info I can on this engine....no secrets here.

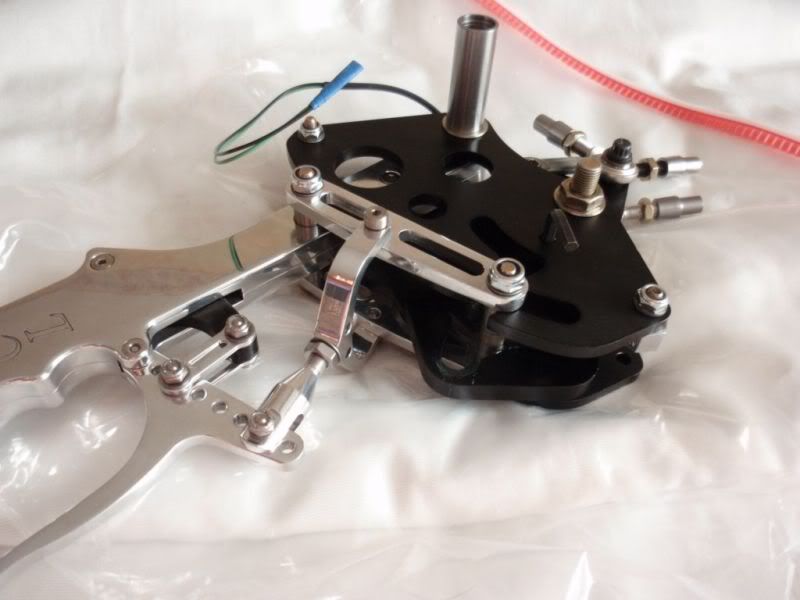

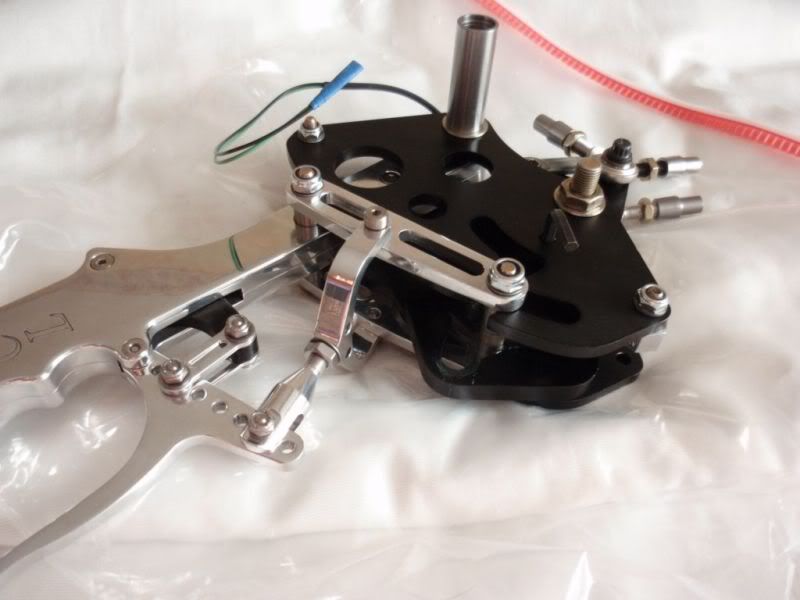

Lightened flywheel machined for Tilton dual disc clutch setup

Marty has just started the intake and exhaust fabrication

Dasdubber - May 31st, 2009 at 03:40 PM

Intake plenum fabrication is next on the agenda

Some more hand porting of the manifolds will occur after the fab work is complete

TCE throttle body (unsure of exact size)

Custom ball bearing turbo (don't have exact specs sorry)

Cheers

Al

mountainbug - May 31st, 2009 at 04:19 PM

You certainly picked a man who knows his stuff. Ive followed a few of his builds.

What Hp are you expecting in this monster.

RISKYBUG - May 31st, 2009 at 05:50 PM

great stuff mate !!!!

what cam will it run?

vassy66T1 - May 31st, 2009 at 06:19 PM

Wow Alan!!

That really looks the goods. Will we see it this year?? Warwick maybe?

typethreeking - May 31st, 2009 at 06:23 PM

lookin good alan, cant wait to see this in the oval, should wake it up a little...

Dasdubber - May 31st, 2009 at 11:57 PM

Hi guys, yep the engine will end up in the 54 oval - unfortunately not this year for warwick due to time and funds required to get it back to oz, then

purchase injectors and ECU, tuning, fuel system etc etc etc. Next year though!

I didn't knuckle Marty down for cam specs just yet - all I know it is his custom profile designed for turbo application based roughly on a K8.

Yep Troy, should definitely wake it up!

Al

He estimates it should be good for roughly high 300's, close to 400hp at the flywheel depending on boost etc. Always hard to know until its actually

on the dyno....more interested in the 1/4 mile times!

Bizarre - June 1st, 2009 at 08:00 AM

WOW!

vassy66T1 - June 1st, 2009 at 09:01 AM

Yeh, patience is a virtue Alan. (More like a frustrating PITA but that is life  )

)

Progress is good.

Camo - June 1st, 2009 at 09:46 AM

| Quote: |

Originally

posted by Dasdubber - happy to share any info I can on this engine....no secrets here.

|

Don't mean to be rude, but are you able to share what this may be costing you.

Cheers, Kev

P.S. You lucky bastard

Dasdubber - June 2nd, 2009 at 02:58 AM

I bought it as an unfinished engine that a guy in the UK had commissioned Marty to build. His plans changed half way through (sold his beetle and went

to a Fiat which the engine would have been too much for), so he advertised it on the cal-look forum over a year ago. I would have had something like

this built locally in Oz but the price I got it for would have barely covered the parts alone never mind the labour to build it, so I jumped on it.

Although I'm not wanting to be evasive, I better not reveal the cost of the engine in case my wife happens to read this thread

Al

bajachris88 - June 2nd, 2009 at 07:38 AM

friggen sweet!

Just a question though, is it wise having a lightened flywheel on a turbo setup?

LIFE IN THE LOW LANE - June 2nd, 2009 at 10:23 PM

Troy has a lightened flywheel on his set up in his Type 3. Just means once it really builds boost the tacho needle moves bloody quick to the limiter.

Light flywheel = less mass to have to spin up robbing HP!!

Al as you would know the little things that could and will go wrong will prolly happen so Warwick next year will be an achievable goal.

bajachris88 - June 2nd, 2009 at 10:28 PM

yea i was just curious thats all...

because in the ricer forums there was discussion that the spool time for the turbo takes longer with a lightened flywheel as the throttle is less

depressed as extravagantly compared to teh 'less revvier' factory flywheel. (as it requires less throttle to 'rev' up with a lightened

flywheel)

In turn, more throttle, more air flow, more air flow in exhaust manifold, faster spool.

I think the discussion was more in regards to launching from the line, i'm not 100% sure, but was a rule of thumb some guys were pushing forward. I

thought it would be good to bring up and question.

But they were stating that the benefits of maintaining a normal flywheel over lightened in a turbo application was more beneficial performance wise,

in all its irony.

colonel mustard - September 25th, 2009 at 12:12 AM

That engine looks amazing. nice stuff. any updates on it??

fish26 - September 25th, 2009 at 11:17 AM

| Quote: |

Originally

posted by bajachris88

yea i was just curious thats all...

because in the ricer forums there was discussion that the spool time for the turbo takes longer with a lightened flywheel as the throttle is less

depressed as extravagantly compared to teh 'less revvier' factory flywheel. (as it requires less throttle to 'rev' up with a lightened

flywheel)

In turn, more throttle, more air flow, more air flow in exhaust manifold, faster spool.

I think the discussion was more in regards to launching from the line, i'm not 100% sure, but was a rule of thumb some guys were pushing forward. I

thought it would be good to bring up and question.

But they were stating that the benefits of maintaining a normal flywheel over lightened in a turbo application was more beneficial performance wise,

in all its irony.

|

It also depends on the engine type and combo used, a car with light flywheel needs a lot more torque down low to get it out of the hole, hence ricers

use heavier flywheel since their peak torque/hp is way up in the rev range and close together.

Alan will have no problem due to capacity/heads/cam/turbo combination that Marty has put together, he invests a lot into cam R+D and I think that some

things should stay a mystery, I was having a chat with him not long ago about a person walking into his shop and asking all sorts of technical

questions about a certain race car, Marty's answer being "Why don't you just buy the damn thing for $******.** you'll get a car + all 30 years of

development for free.

Mate, its gonna be a heck of an engine, I'm sure you'll also have a car thats up to it.

Dasdubber - September 25th, 2009 at 06:36 PM

Cheers fish, I am looking forward to getting it to Oz some time before the end of the year. I'm not pressing Marty at the moment because he is flat

out with Turbosmart (head of US operations now) and my funds aren't freely flowing at the moment so even if it was here tomorrow, I still need to

save for ECU, injectors etc etc.

Al

fish26 - September 26th, 2009 at 12:08 AM

Yeah I heard he's going nuts with Turbosmart, the right guy to carry it, people don't understand how much knowledge is in that outfit.

You gonna run the 550cc from Mazda with Microtech or a different combo?

Looking forward to the rest of this thread. re. ben

Dasdubber - June 8th, 2010 at 02:48 PM

Been a long time between drinks (updates) but I just visited Marty again whilst I am over in the US for the Bugorama/Classic etc. To his defence I

have not pushed at all to finish the engine which is why it has taken so long (I know running a resto business what it is like to try and deal with

customers who jump up and down, but being so laid back means things can sometimes be put off).

Nonetheless things are getting close to completion now - intake is all done (apart from some ceramic coating), and most of exhaust is done (although

not pictured here as Marty had to pull some bits off to take the turbo and clutch as backup for Sacramento (didn't need either)....similarly a small

claim to fame is my JCL shifter I recently purchased went into Roger Crawford's super street car for his last round at Sac due to problems with

his....it was pulled out after his elimination, and dropped back to Jim Larsen who is doing a line lock button mod to it (machining wiring passages

down through the handle etc) - hoping to get it before I leave the US.

Anyway, enough blah blah.

Dasdubber - June 8th, 2010 at 02:53 PM

Will get Marty to sort out the injectors and fuel rails as well but will source ECU here as I am somewhat dictated by dyno tuner and his

familiarity/preference. At this stage it looks like Autronic SM4 but that may change pending further research.

So that is probably the end of the updates for a while until it lands in oz unless I update shifter install etc....warwick is unfortunately unlikely

this year as you all should know the time it takes to shoe horn something like this into an engine bay. Plus by the time I pay to freight it home and

bend over for customs duties/taxes etc, I won't be able to afford the ECU etc

Al

Bizarre - June 8th, 2010 at 03:19 PM

W........O................W

typethreeking - June 8th, 2010 at 05:11 PM

lookin good allan, sm4 autronic is what i am running and once tuned its great. I added at cdi ignition which is also autronic. Cost is up there but

well worth it, bet your looking forward to it landing here so you can start work, keep us posted

2443TT - June 8th, 2010 at 07:27 PM

Very pretty indeed! What cam did you end up running?

LIFE IN THE LOW LANE - June 8th, 2010 at 07:50 PM

Sweet Al. Looking very noice indeed.

reub - June 8th, 2010 at 08:36 PM

and

and

Seeing this stuff on the forum does get me going... pure volksporn dude.

Dasdubber - June 20th, 2010 at 09:32 AM

Still waiting on the cam specs - maybe Marty wants to keep his custom grinds close to his chest

No updates on the engine, but got a bit warm and fuzzy after the classic when I picked up my new JCL shifter with the first RHD line lock button mod

performed by Jimmy Larsen. Couldn't afford to buy any other parts after paying for the shifter but its a nice bit of kit, and something different so

I though what the hey.

Al

Stanley - June 20th, 2010 at 11:26 AM

That is nice Al....good score

grogy - June 20th, 2010 at 06:53 PM

thats a very nice set up, i noticed u have a dtm shroud, i read about them. have u heard much feedback from those that have them or does marty staggs

recommend dtm. i look forward to seeing the finished product. regards greg

Dasdubber - June 20th, 2010 at 07:02 PM

hi greg, I ran a DTM on my type IV (close to stock 2L) in my ragtop beetle after running the sharpbuilt kit and noticed a consistent 10-15 degree (F)

reduction in oil temps. I did not have head temp sensors so can't comment on that. Jake Raby has done a lot of testing with the type IV setups (with

CHT readings) and seems to be fairly transparent in publishing his findings......although at the end of the day he is not totally independent as he

sells the products. Not suggesting he fudges any results, just noting the link.

I don't think Marty generally uses the DTMs as 90%+ of his motors are run without shrouds anyway - the guy I bought the unfinished engine from had

the DTM already so I decided to stick with it. Not the most attractive aesthetics but must admit I like the idea of the air being pushed down between

the 3/4 cylinders rather than mostly over #4 like a stock shroud with cooler inside (even doghouse). Just my 2c, I'm sure others will be able to

provide input. I am not too worried as it won't be doing any long trips in hot weather (mostly around 400m at a time)

Al

)

)

and

and