Type 1 2275cc Engine*SOLD*

66deluxe - August 27th, 2006 at 07:18 PM

Hi all, i have just finished rebuilding this type 1 2275cc engine for my friend Steve, it was originally built by Stan Pobjoy over 10 years ago, i

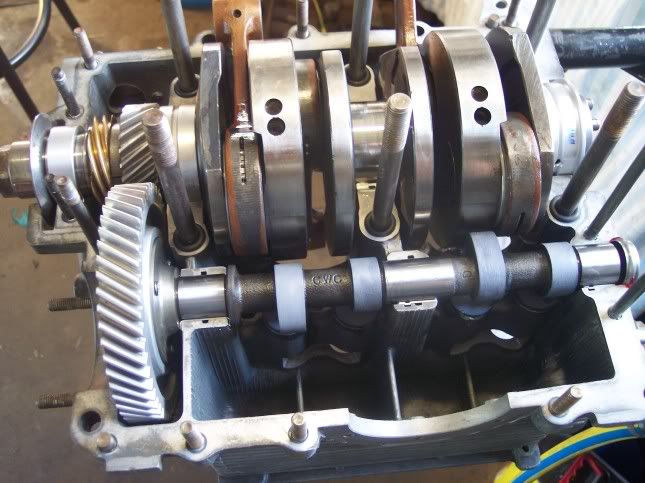

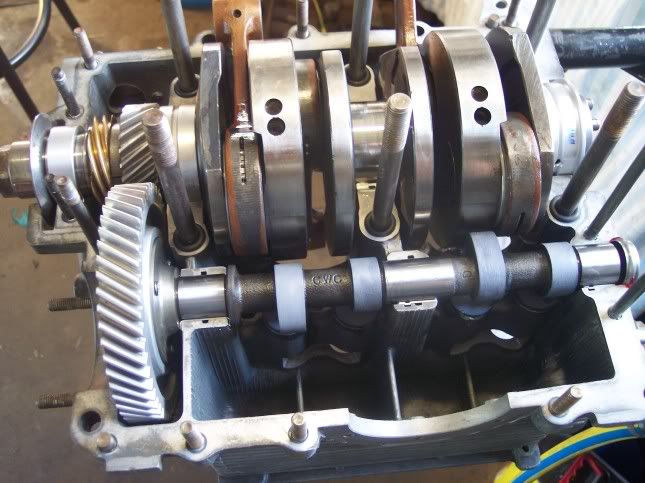

have just simply rebuilt with new crank and cam bearings, new piston rings and new gasket kit. The engine has a SPG Roller crank in it. I have a

list of all measurements obtained in the build: 2275cc Roller Engine Assembly tolerances:

Camshaft Axial Play : 0.06mm

Camshaft gear to crank gear backlash: 0.02mm

Cylinder Shims: 1.15mm

Crankshaft endplay: 0.09mm

Deck height TDC: #1 1.78mm #2 1.81mm #3 1.78mm #4 1.76mm

Head CC: #1 67cc #2 67cc #3 67cc #4 67cc

Calculated Compression Ratio: 8.1:1

Total valve lift : 0.460” or 11.68mm

Valve geometry set @ Half total lift: 5.84mm

Stroke: 82mm

Bore: 94mm

Rocker ratio: 1.25:1

Crank mains: 0.25mm under ID, OD standard

Before assembly i have cleaned all parts very thouroughly at my work were i have access to excellent cleaning equipment as i overhaul aircraft

engines. The case has also been crack tested by our NDT guy, using Flourescent Penetrant inspection technique and the case has no cracks to be found

in the usual areas as well as the rest of the case. I also had the cam and lifters reground by Tighe Cams, and have the cam tolarances also. The

engine is equipped with 40 IDF Webbers, 009 Dizzy with electronic ignition and the heads are original 041 heads with heavy duty single springs,

lightened flywheel and deep sump extension. Selling price requested by my friend is $4000 negotiable, Contact me either by U2U or on 0405464872,

please ring only after 5pm monday to friday or anytime on Saturday and Sunday. I am in North Brisbane (Murrumba Downs). I also have video footage of

this engine running before overhaul, the engine in it's current state has not been run yet. Here are some photo's of the rebuild. Cheers

Damien.

Complete engine.

Cleaned parts ready for assembly.

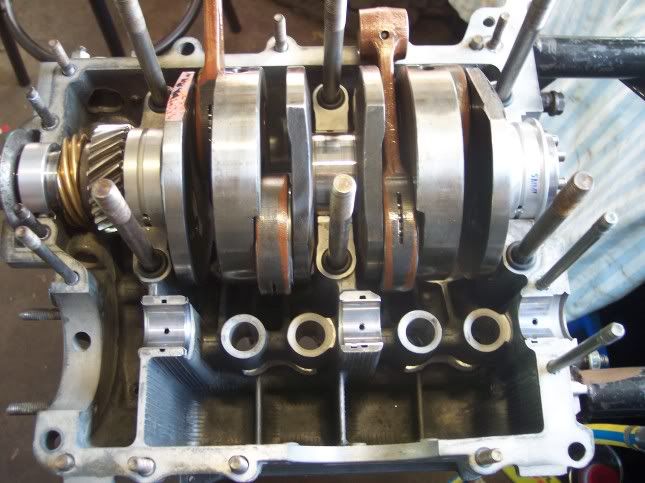

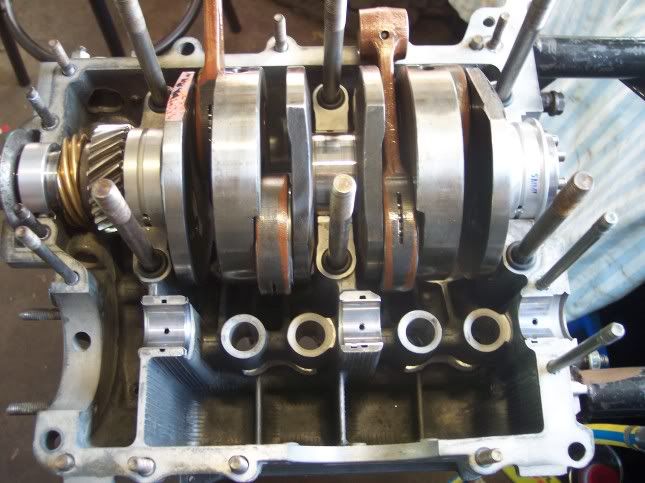

Assembly.

[ Edited on 27-8-2006 by 66deluxe ]

[ Edited on 30-8-2006 by 66deluxe ]

[ Edited on 2-9-2006 by 66deluxe ]

[ Edited on 2-9-2006 by 66deluxe ]

Dasdubber - August 27th, 2006 at 08:47 PM

Nice work Damo, good luck for the sale for your friend. Can't wait to see how your type IV turns out with that level of quality and attention to

detail!

greenman - August 27th, 2006 at 09:38 PM

66deluxe

you have u2u

lohoon - August 27th, 2006 at 10:04 PM

U2u'd also

Volksaddict - August 28th, 2006 at 03:17 PM

Now that would push the Frid along!!!....detail..smick oh!!

66deluxe - August 28th, 2006 at 07:24 PM

Thanks Alan, i am itching to build my type 4 just have to get pistons and heads, then i will build. Cheers Damo.

reub - August 28th, 2006 at 08:12 PM

I expected to see this bad boy sold by now....

dangerous - August 28th, 2006 at 08:51 PM

Hi Damo,

Did you mod the main bearings for the oil spray?

aintgotitmusthaveit - August 29th, 2006 at 01:19 PM

Can you give the engine #s for it.

Is it based on a 2litre combi engine?

Where the sleeves changed?

Does anyone have any experience getting a 2 litre into a type 1 and registering it with vicroads?

56astro - August 29th, 2006 at 01:37 PM

| Quote: |

Originally

posted by aintgotitmusthaveit

Can you give the engine #s for it.

Is it based on a 2litre combi engine?

Where the sleeves changed?

Does anyone have any experience getting a 2 litre into a type 1 and registering it with vicroads?

|

| Quote: |

i have just finished

rebuilding this type 1 2275cc engine

|

It IS a type 1 motor, 2275=82x94

1500king - August 29th, 2006 at 09:27 PM

I hope you grooved the main bearings for the oil spray to the big end roller bearings(as per the reply by Dangerous)... also, was the crank pinned(if

this is not done, the crank will twist as soon as you give it a little boot).seen many motors die this way, just want to warn you before it is too

late.(all that money...ugghhhh)

1500king - August 29th, 2006 at 09:38 PM

a type 4 longblock is actually narrower than a type 1 longblock- no issues here. Use a 1800 kombi flywheel, get the centre drilled for the mainshaft

pilot bearing(which needs to be pressed into the flywheel), your car needs to have a post 1970 (12V of course) box which has the clutch TO bearing

sleeve for the 1800 clutch pressure plate, get a T4into T1 conversion kit(sharpbuilt??) and off you go... just tell the inspectors your old motor blew

up! you will also need to sort out the exhaust system.

newoldmanx - August 29th, 2006 at 09:39 PM

what is pinning the crank??? are these a two piece crank

1500king - August 29th, 2006 at 09:46 PM

the crank is pressed together at the big ends as the rods do not dismantle like a conventional rod

1500king - August 29th, 2006 at 09:50 PM

They are more than two piece, so if every journal is not drilled and pinned with a bloody large, hardened pin, you will run into trouble.

1500king - August 29th, 2006 at 09:53 PM

They are a 5 piece crank!

newoldmanx - August 29th, 2006 at 09:59 PM

im looking for a goodmotor for a manx tis all

newoldmanx - August 29th, 2006 at 10:02 PM

im looking for a bit of power and would like to turbo charge it wadda you rekon

1500king - August 29th, 2006 at 10:22 PM

you will still need to get the type 4 crank counterweighted to utilise fully the power gain from the turbo and also avoid making a mess of the centre

main bearings.(and maybe breaking the crank). a type 1 with a good aftermarket crank and properly prepped case will do the job just as well. it is

also lighter!

1500king - August 29th, 2006 at 11:12 PM

well the crank could have been built by one of these...:sandrine

Any other SPG owners out there?

guys, do your homework.

[ Edited on 29-8-2006 by 1500king ]

[ Edited on 29-8-2006 by 1500king ]

newoldmanx - August 29th, 2006 at 11:21 PM

| Quote: |

Originally

posted by Craig Torrens

| Quote: | Originally

posted by 1500king

the crank is pressed together at the big ends as the rods do not dismantle like a conventional rod

|

Stop it ,you're killing me:P

|

what does this mean????? i cant see any bolts on the rods in the pics!!are you saying its not true and in your opinion would this type of motor suit a

manx application???

1500king - August 30th, 2006 at 12:00 AM

check out some of the threads on thesamba.com about spg roller cranks. these should clear it up for you, click below...

http://www.thesamba.com/vw/forum/viewtopic.php?t=161496

[ Edited on 29-8-2006 by 1500king ]

newoldmanx - August 30th, 2006 at 12:25 AM

thanks mate but still seems to be a lot of uncertanty on weather their good or bad what is your opinion have ou used one this motor seems good value

for dollars i was quoted $7500 by pobjoy for a counterweighted 1916cc

bond - August 30th, 2006 at 12:35 AM

this motor would rock in anything! its an exceptional build by stan and rebuild by damien. well worth the $. couldnt build one for that. if i had the

coin it would have been snapped up 3 months ago before i went to europe!

goodluck with the sale

nick

ps. i think the compression is fine for turboing. or just leave it n/a. its going to push a manx along something chronic - just my 2c

[ Edited on 29-8-2006 by bond ]

newoldmanx - August 30th, 2006 at 12:46 AM

thanks mate do you know damien?? is he a reputable builder i drive my cars pretty hard and im constantly trying to squeese more out of my 13bppt

66deluxe - August 30th, 2006 at 10:18 AM

Seems i have a few questions to answer, first the crank, i am not sure if the crank has been pinned, but i do know that when my mate was driving it he

would take off hard occasionaly, when i measured the crank on V blocks at work it meassured true and round and this was reflected by the numbers found

when measuring TDC and Deck Height. As for the main bearings for oil spray i searched everywhere for the correct information, but could not find any,

also when i compared the new bearings to the old ones they are the same, if any one has correct info and method/pictures of the mod i would be

prepared to dissasemble and carry out the mod. Here's some pics of the bearings old and new:

As for myself as an engine builder and reputation i have none, all i have done is build engines for friends and myself, stock and performance examples

of these are stock type 1 and type 4 builds and a 1776, 1916 and the 2270 type 4 that i am building for myself and this type 1 2275 rebuild. I have

just finished an apprenticeship in Aviation Engineering with Pratt & Whitney where i Overhaul turboprops and turbofan Gas turbine engines, and i can

fully overhaul these aircooled monsters, all my engines at work have passed testing first time in the test cell, and these have been a total of six so

far in the last two months. Hope this has helped, thankyou Damien.

aintgotitmusthaveit - August 30th, 2006 at 01:01 PM

u2u sent

66deluxe - August 30th, 2006 at 05:30 PM

Aintgotitmusthaveit i have not received a U2U from you.

LUFTMEISTER - August 30th, 2006 at 10:35 PM

nice work damo

1500king - August 30th, 2006 at 10:42 PM

see below for correct oil grooves in the main bearings. without these, the big ends will be scorched.

http://www.amayesing.com/vwengine.htm