65' Deluxe

MAT792 - November 8th, 2010 at 10:12 PM

Hey guys,

First topic here but shes a goody, well for me anyway.

as of 9.30 tonight I am the proud owner of a 65 bug

It's my LONG term project and i hope to have it finished by 2012ish

excuse the crappy iphone photos but thats all that i have till after work tomorrow,

Scarab - November 9th, 2010 at 08:21 PM

well done mate! congrats on the new project....no idea how good it is from the pics, guess we'll have to wait for some decent ones!

I just bought a 65 too....we can compare photos!

Scarab (aka: Paul)

MAT792 - November 11th, 2010 at 10:20 PM

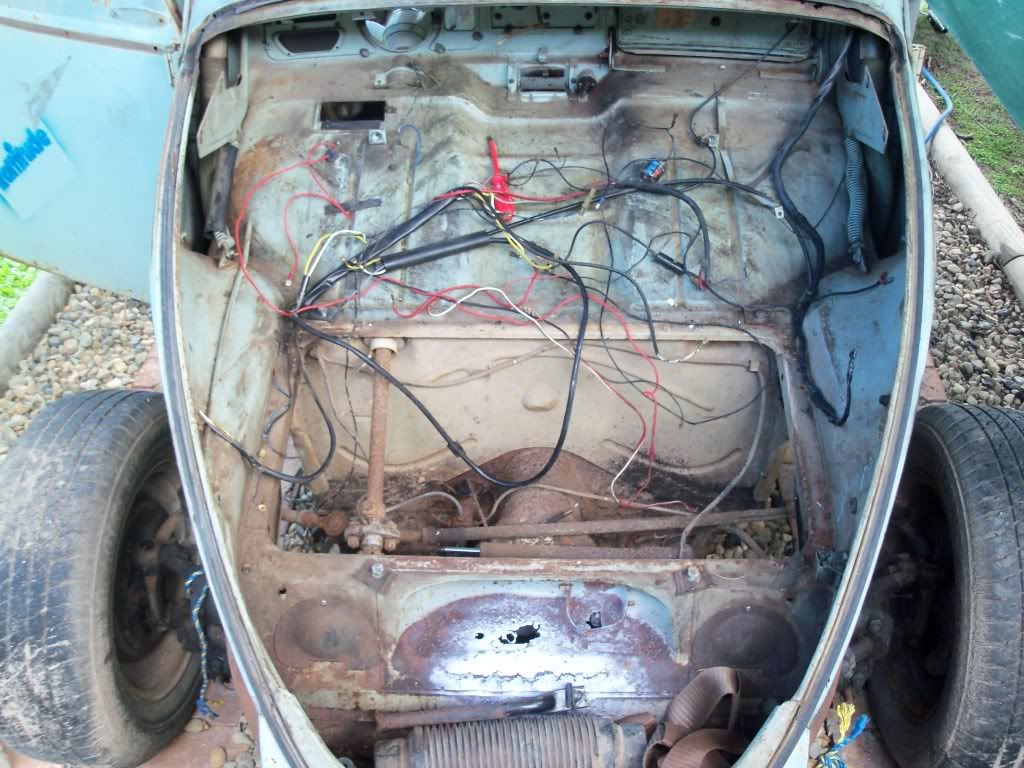

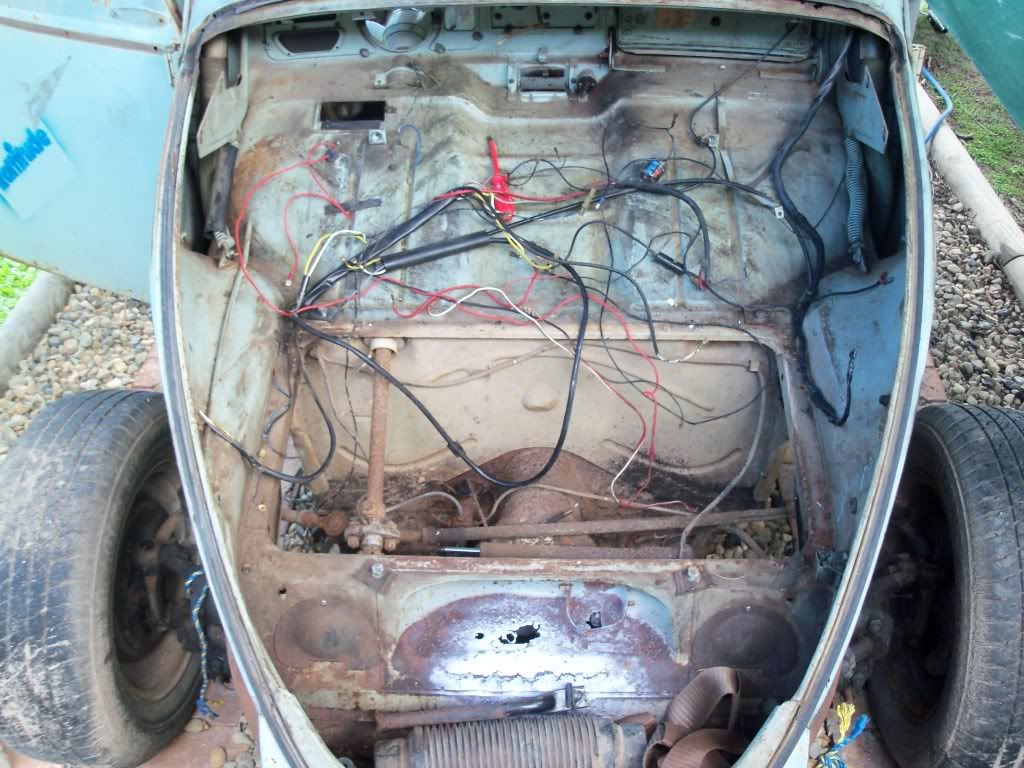

here are the pics

going to be started this weekend

lots of work ahead of me.

Interior and disassembly pics throughout the weekend

Paulc1964au - November 12th, 2010 at 06:12 PM

looks ike a big job but will be worth it in the end

phoenix_dr - November 13th, 2010 at 12:00 AM

LOVE IT!!!!!!!!!!!

Strip it and have fun with it

vw54 - November 13th, 2010 at 06:14 AM

welcome to the 65 club I have 2

looks like abit cancer there

MAT792 - November 14th, 2010 at 09:39 AM

yeah it has a ton of cancer, needs 2 new floor pans, some repairs on the rear guard mounts and a full drive train overhaul

lotsss of work ahead of me

bugsandoil - November 14th, 2010 at 12:34 PM

Hi Mat,

I've just bought a project too.

I need to replace my floors and spare wheel well.

Was just wondering how you were thinking of tackling these areas??

I'm thinking of just buying whole new floor pans.

I hear wolfsburg are making good ones at the moment.

I'm not sure about the spare wheel well though, haven't had any recommendations of where to buy those yet.

Any thoughts??

Good luck.

It'll be good to see another one on the road in in Brisvagas eventually.

Carl

rubyred64 - November 15th, 2010 at 06:35 PM

ooops wrong account :S

meant to be on MAT792 not this one

MAT792 - November 15th, 2010 at 06:36 PM

Gday bugsandoil,

congrats on the buy!

as for rust ill be cutting the floor pans out and getting new ones in there

i have got quotes from mick motors for floor pans at 154.00 each so not as bad i was thinking,

but im lucky with my spare wheel well being in really good condition!

are you going on body resto or off body?

look forward to seeing your progress! maybe we can swap tips :P

bugsandoil - December 5th, 2010 at 09:45 AM

Hi Mat,

I've finally started my own thread under 'members rides.'

'Lichen 1500 bug.'

Any progress on yours?

Carl

MAT792 - December 6th, 2010 at 05:38 PM

nahh mate rain and moving has been keeping me away from it,

if it fines up a bit tomorrow might have another go but nothing at the moment,

MAT792 - July 23rd, 2011 at 02:07 PM

well its been 7 months since I have updated this! so heres a bit more

so basically since my last update, I started a new job, did a lot of stuffing around, went out a bit as young people do :P, went to a few car shows

(each making me want mine done faster) and slacked off a bit. I have had it stripped down for a while now but its still "water tight" if you could

call it that :P, so when I get home in 2 weeks after a 6 week working stint in darwin I will be getting a shed, putting all parts in said shed and

getting the glass out!, the first metal will be new floor pans, I hope to get the body off and back on with new pans in 1 weekend (to minimise chance

of body flex and other damage. Im still unsure wether I want to replace the heater channels or just weld them shut though... a new welder has been

purchased and I'm pumped to get into this thing and get it drivable!

heres some photos of progress!

Sir Grinds-a-lot ( I have since started using quick strip discs which are much faster and nicer to the body)

I quickly learnt to wear long pants or hold on tighter!

little bit of rust in this one! (soon to be replaced)

Interior all cleared out, any ideas on how to get all the heshen strands off? just grind it?

my lovely girlfriend stripping the roof lining, and interior bits and bobs

wiring loom almost out, interesting job that one! probably my favourite thing done so far

all empty! ready to be stripped and primed

same with all the dash components (all of which are fairly clean, will be getting a good polish before re-entering him though)

striping the hood down! very little rust in this at all surprisingly!

all etch primed

and thats where I got to before I left for darwin.

more soon!

MAT792 - April 10th, 2012 at 07:59 PM

so after moving house, and sitting dormant for a long time I finally got some time over the Easter long weekend to spend some time on my little rust

bucket.

Saturday afternoon my girlfriend Emma and I began to take out the windows, managed to get all of them out in about an hour and I should mention

without breaking anything at all! ( which we were surprised about :P )

sunday afternoon we got the urge again to go outside and have a play which resulted in the body magically falling off the floor pans! a major

accomplishment in my books, after over a year of farting around and putting things off he has finally been seperated from his underside.

which leads me to the best part! driving home from work today I was thinking about where to get my floor pans, classic vee dub has been at the top of

my list offering a very good price on pan halves ($102 a side I think) when I arrived home to an early anniversary present from the ever lovely Emma,

so hopefully from here on in it will be full steam ahead

[

I still need to get new heater channels and lower covers but they will come in good time, this months project is to have the old floor pans out,

remainder of the chassis wire brushed and repainted with a little added rust protection!

hopefully next time it wont take another 6+ months to update :P

thanks for reading!

beetleboyjeff - April 10th, 2012 at 11:03 PM

Good to see progress like that - and I reckon Emma has got to be a keeper. :-)

MAT792 - April 15th, 2012 at 03:47 PM

you are most certainly right! keeper for sure, always keen to lend a hand

got a bit of wet weather this weekend and I had a bee in my bonnet to build a dolly to put the body on to keep it off the ground, 80 bucks worth of

metal and a few hours later I had myself a dolly.

I had some wheels laying around but unfortunately it will be rolling over grass and gravel they wont do  will have to get some heavier duty ones.

will have to get some heavier duty ones.

donn - April 15th, 2012 at 04:24 PM

Mate, check the creeks and paddocks for stuffed shopping trollys, the wheels are excellent for the dollies.  though you do need to be a bit selective, you need the ones with the full rubbewr tyres, BTW, what

happened to the bonnet, one shot it's a nice blue etch prime then it's back to rat.

though you do need to be a bit selective, you need the ones with the full rubbewr tyres, BTW, what

happened to the bonnet, one shot it's a nice blue etch prime then it's back to rat.

MAT792 - April 15th, 2012 at 05:15 PM

will have to keep an eye out for some shopping trolley ones! cheers for that idea, these come of data cabinets (get them free from work) so had to

give them a go, as for the bonnet the car sat idle under a tree at mums for a couple of months and in that time managed to re rat itself, will have

to strip it again and re do it,

grimbear64 - April 28th, 2012 at 09:55 AM

Hi Matt I have just got 65 bug one of my employees gave me for a birthday present

Yes his employee of the year yours is coming along nicely look forward to more updates

MAT792 - May 7th, 2012 at 08:37 PM

sounds like you have a good staff, id be giving that bloke a promotion :P

MAT792 - May 7th, 2012 at 08:51 PM

so its been a slack few weeks, I started drilling all the spot welds out, went through a dozen and a half drill bits and i still think that I'm doing

it wrong... however a mate put me in the direction of a spot weld drill bit so I've since brought one of those and it seems to go okay..

I've mad a trolley for my welder and gas bottle makes getting it round the backyard/ barn a bit easier needs larger wheels to handle the rocks

though...

apart from that I have done a bit of wheeling and dealing somehow managed to get onto Grahame quickly and scored this beast of a 58! It seems very

doable to me so looks like ill now have two projects on the go!

more photos to come.

p.s if anybody has a early front cut/clip that they are looking to get rid of (for a reasonable price) in the brisbane/south east qld/ far north nsw

region please let me know!

and last weekend a few friends, my girlfriend and I paid a visit to the Gold Coast Vee Dub show at heritage park! had a great day and came home with a

few little goodies for myself! I dunno if I paid too much but im stoked with the oval window clip that I scored! by the time it comes to put this bad

boy in we will have rewelded a few in!

and to finish a big congrats to my mate Dan for picking up a top 10 place this weekend, I absolutely love this bug! and he is a top bloke too! always

good to teach me something and lend a hand picking up bulkier parts :P

I am also searching for a new early chassis around the same area as the front clip, it needs to be a roller with wheels so we can move it around

easily, floor pan condition is not a problem ( easy enough to change )

MAT792 - June 4th, 2012 at 06:08 PM

more progress! the sun poked its head out long enough on sunday for me to pull my finger out and get stuck into these floorpans! managed to get both

off in the one go (with lots of work drilling out before hand), I spent about 4 hours drilling out the last of the spot welds and peeling the old pans

away! At some point in the next weekend or 2 I'd like to strip the pan down a bit more and get a wire brush onto the remains for a good clean up,

will just have to see how lazy I feel

anywho here are some pictures of where I left it sunday arvo.

LUFTMEISTER - June 4th, 2012 at 08:09 PM

Hey Matt Handy hint for next time. do not drill out all the spot welds. just cut as close as you can to the main chassis spline then get under the pan

skin and peel it back along the spline. After removing pan metal just grind down spot welds till flat again. This will not weaken your welding area.

Ps Will save a shitload of time too

MAT792 - June 8th, 2012 at 07:33 PM

Thanks Marcus, definitely wouldn't do it that way again! In the ended I peeled it back. not looking forward to welding all the small holes....

MAT792 - July 5th, 2012 at 02:20 PM

so I have had this week off of work and managed to make a tiny bit of progress. I have trimmed the floorpans to size and removed the jacking points as

I don't plan on using them to actually jack the car up. I'm happy with how they sit but I will leave it a tad longer before I weld them on as they

will be outside for a bit longer.

Also if anybody has tips on final fitting of the floor pans ill take any help I can get. Should I sit the body back on and tighten a few of the body

to pan bolts back up to ensure everything is aligned properly? or is there a better method?

anywho here is a pic of the new pans.

MAT792 - July 8th, 2012 at 09:09 PM

So I spent the better part of the morning helping fix my girlfriends 64 but managed to get onto my own rustbucket at about 1, I finally plucked up the

courage to weld the new floorpans on and I'm happy with the progress so far!

I have an rdo tomorrow so I'll be going out in the morning to get some seam sealer to finish it up.

At some point in the next fortnight I want to get the gearbox out and take it to be serviced/ checked over so while thats off I will paint the whole

floorpan/chassis assembly.

heres a few photos. Enjoy!

MAT792 - July 9th, 2012 at 02:09 PM

so I spent this morning ( my final day off work  ) finalizing the welding of the floorpans and seam sealing! went alot better than I thought. the bottom looks like a dogs breakfast but hey! its the

bottom and I'd rather it look messy and be sealed than leak water. For the top side I decided I'd tape it up and try to make it alot neater! Im

very happy with the results so it was worth the extra time

) finalizing the welding of the floorpans and seam sealing! went alot better than I thought. the bottom looks like a dogs breakfast but hey! its the

bottom and I'd rather it look messy and be sealed than leak water. For the top side I decided I'd tape it up and try to make it alot neater! Im

very happy with the results so it was worth the extra time

I also purchased the paint for the chassis this morning so next weekend I will be stripping the pan down and taking my box off to be serviced, have

been told to give Phoenix Engineering a go for the service, does anybody have any experience with these guys?

anywho have some pictures!

also if any mods happen to see this post is there any chance that I can get my thread moved to members rides? please and thank you

Pumba - July 9th, 2012 at 07:25 PM

Did you drill through the new pan halfs and plug weld it,or just tack weld the edges of the pan halfs???

MAT792 - July 9th, 2012 at 08:06 PM

tack welded it to begin with and then when they were held in place i plug welded about 50% of the holes

Pumba - July 9th, 2012 at 09:33 PM

No worrys,have you test fitted a seat on the runners,i used the same pans as you but have not yet tested a seat to see how good the runners are.

will have to get some heavier duty ones.

will have to get some heavier duty ones.

though you do need to be a bit selective, you need the ones with the full rubbewr tyres, BTW, what

happened to the bonnet, one shot it's a nice blue etch prime then it's back to rat.

though you do need to be a bit selective, you need the ones with the full rubbewr tyres, BTW, what

happened to the bonnet, one shot it's a nice blue etch prime then it's back to rat.

) finalizing the welding of the floorpans and seam sealing! went alot better than I thought. the bottom looks like a dogs breakfast but hey! its the

bottom and I'd rather it look messy and be sealed than leak water. For the top side I decided I'd tape it up and try to make it alot neater! Im

very happy with the results so it was worth the extra time

) finalizing the welding of the floorpans and seam sealing! went alot better than I thought. the bottom looks like a dogs breakfast but hey! its the

bottom and I'd rather it look messy and be sealed than leak water. For the top side I decided I'd tape it up and try to make it alot neater! Im

very happy with the results so it was worth the extra time