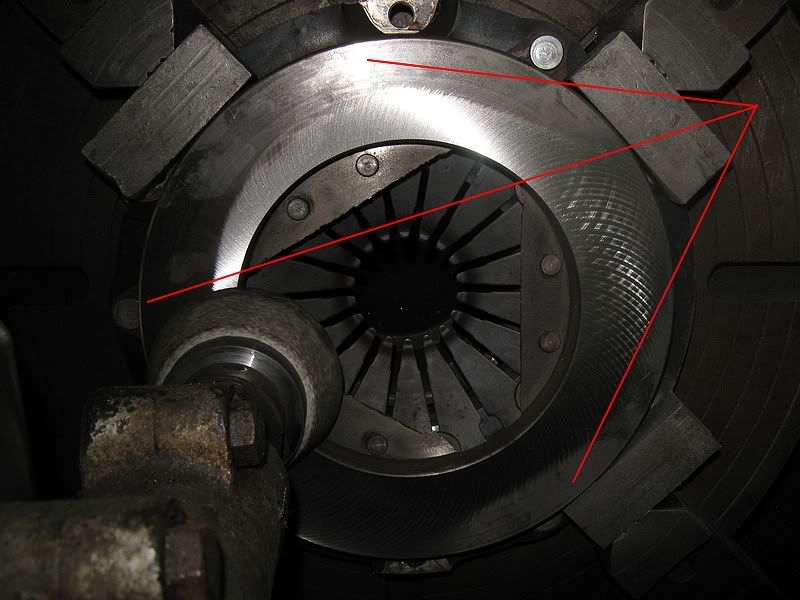

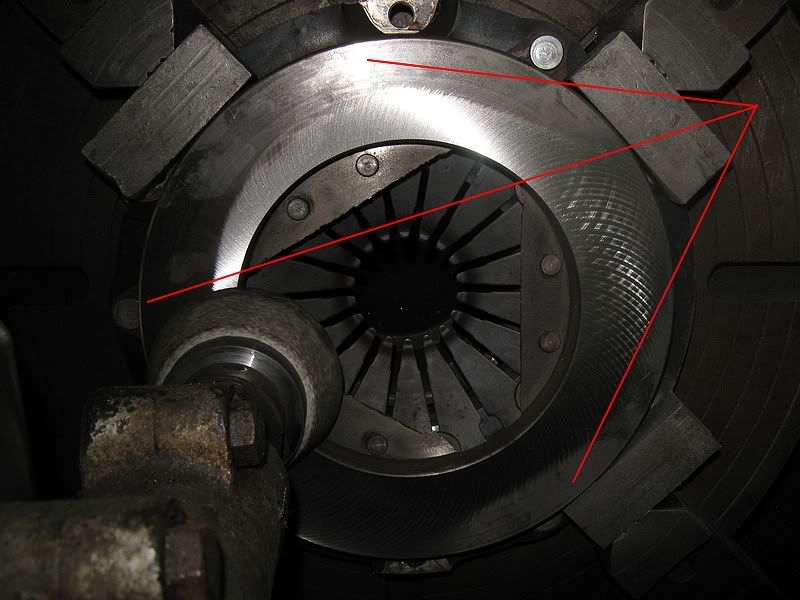

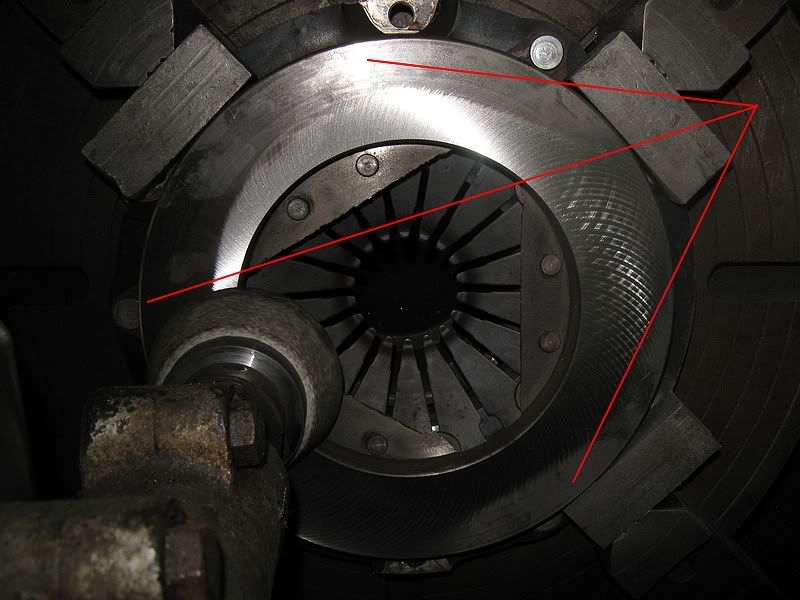

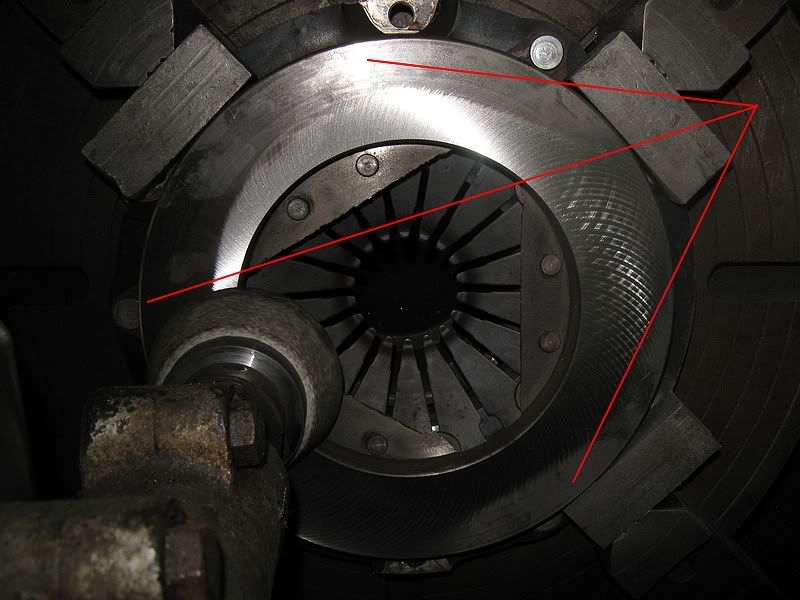

pressure plate fingers uneven again ???

cnfabo - September 27th, 2009 at 11:17 AM

okay, my clutch was slipping so i checked all the easy stuff first, peddle free play,bowden tube,peddle adjustment etc. all good...

so i pulled the engine out and there seems to be a bit of oil in the bellhousing, but no oil on the flywheel, so that rules that one out.

but the fingers are uneven,very uneven,. this is the second time this has happened to a stage 1 preesure plate iv had... the throw out bearing "new"

is central over the input spline,and the clutch fork "new" is not overly stiff either..

what the forking is going on....

the flywheel has no hotspots...

thanks. fabo....

ian.mezz - September 27th, 2009 at 12:25 PM

I had one that the bell housing bolt holes was that worn from just from being old that it caused a problem like that A different box with out flogged

out bell housing bolt holes and it never happened again

OZ Towdster - September 27th, 2009 at 06:00 PM

Check your pressure plate is bolted down correctly and not sitting up on an edge somewhere as from what you have said it sounds like it is not

cnfabo - September 27th, 2009 at 07:45 PM

the pressure plate has been in for about 4 months, if i didnt bolt it in properly, wouldnt i of had problems straight away??

grumble - September 27th, 2009 at 08:47 PM

If the pressure plate is uneven the clutch should shudder not slip,if it is a diaphragm plate check for a cracked diaphragm plate,if it is a spring

type check the adjustment on the levers.,to cause slip requires either oil on the plate or lack of pressure on the plate or overadjustment of the

cable.

cnfabo - September 27th, 2009 at 09:46 PM

there was no oil on the plate at all.

it shuddered when letting the clutch out in first. but was also slipping. cruising in 3rd or 4th i could give it a bit and it would slip a shit

load...

now with the adjustment of the cable, i had about 30mm play...thats normal,right??...

volksys, there either easy to fix or totaly a freekin pain in the arse..gotta luv em!!!!!

dangerous - September 28th, 2009 at 05:41 AM

ALL kennedy ressure plates available new need spacers between the FW and pressure plate,

and most, after being used, will need to be re-surfaced.

When ever a clutch is replaced the FW needs to be re-surfaced,

and when boted down with the clutch disc,

the fingers should be a fly's dick above level.

Ball should JUST roll outward.

Put a straight edge across the clutch surface and see how worn and out of shape it is.

The FW will be bogus too, if it has burn marks.

This mesuring and machining is just a standard procedure when ever clutch is installed.

vw54 - September 28th, 2009 at 07:10 AM

the springs may have collapsed get a new one

clinker42 - September 28th, 2009 at 10:00 AM

Fabo

Pressure plates are really simple things, helical or diaphragm springs. If your pressure plate is bolted evenly to the flywheel and your fingers are

un even, then its simply a stuffed pressure plate. A flywheel or clutch will not cause the fingers to be un even. Well in theory it can, but can

you imagine how warped the flywheel or how much friction material would have to be missing from the clutch for the pressure plate to look un even.

What brand are you buying, it is possible that there was a bad batch of steel used for the diaphragm. Excessive heat can also cause diaphragm

failure but I doubt a VW would get that hot.

Chuck in a new one.

cnfabo - September 28th, 2009 at 10:01 AM

thanks,guys...i just cant belive its happened twice..

the flywheel is all good,no burn marks,the disc is good , and the mating surface of the p-plate looks good..

when i instaled it the fingers looked pretty level like u described dave.. when i pulled the engine out i noticed the fingers were slightly uneven

"2-3mm", the n when i unbolted it "opposit bolts,and bit by bit" the clutch fingers went twang, then they ended up about 5mm plus,havent messured

it yet..

when i get a new one should i have it balanced to my flywheel...

clinker42 - September 28th, 2009 at 01:12 PM

Dont worry about the balance, they are usually neutral so it wont matter. If it was a 10,000 rpm race car then you would

cnfabo - September 28th, 2009 at 06:22 PM

thanks clinker, i just put some verniers onto the flywheel and i have a depth range difference of 1.5mm...

but anywhos, we found a part"dont know the name" in the pressure plate that has actualy broken..

lets hope my third kennedy stage 1 will be a good one....

thanks for the help....

clinker42 - September 28th, 2009 at 06:32 PM

Fabo

Why dont you go for an Exedy kit

vw54 - September 28th, 2009 at 08:16 PM

yep they brake very easy

is it a Kennady thats surprising though it may be chinese or brazilian

do the checks as per Dave above

cnfabo - September 28th, 2009 at 10:11 PM

ok its got a cracked diaphram...

whats the cause of this usually??

my previous stage 1 i was using a different t/O bearing and fork which i was using in a previous "nothing broke" engine so it cant be this...

clinker42 - September 29th, 2009 at 12:19 AM

Fabo

It could be heaps of things, from bad steel too poor fitment, throw out bearing etc etc. Grab yourself a good straight edge and a pair of feeler

gauges. Then follow Daves pics, put the straight edge on the flywheel in a dozen spots and try sliding a 2 thou feeler gauge under the straight

edge. Check your flywheel bush, the bush that holds the spigot on the gearbox input shaft, if you have verniers, measure the gearbox input shaft and

then see what clearance you have in that bush. Make sure you are putting the clutch plate in the right way and not reversing it (just guessing VW

is like most others). Fit the new Pressure plate and if you fit one of them Kennedys like in Daves post, make sure you fit the spacers he mentions

(Dave, why do they have spacers?). Fabo, how do you align the clutch when your doing up the pressure plate, make sure you torque it up. Fit a new

throw out bearing and then good luck lol, hopefully you will get more than 6 months

cnfabo - September 29th, 2009 at 10:17 AM

what happened to the ,"just bolt it on application"...

ok it has a new t/o bearing and h/d fork.and its centers over the input shaft.

the first kennedy i had , the fingers got stuffed aswell, but i was using the stock t/o bearing and fork.and this i was using on a previous engine

with stock plate and flywheel and had now problems..

so im assuming its got nothing to do with the gearbox side of things...

i installed the disc and pressure plate with a input shaft i got off a vw mechanic..and torqued the bolts up,opposites, and bit by bit.and i do

remeber when torqued up the fingers were even and slightly above"as dave describes"...

and with the flywheel i already measured with the verniers . and there is a difference of atleast 1mm from the mounting surface to the friction part

of the flywheel..

what is the factory tolerences for this??

and spacers?? im assuming this is just washers that go under the bolts to make sure u get the right level with the fingers when torqued up... never

heard anyone do this before..

oh yeah, a mate of mine, his new pressure plates fingers screwed up aswell same time my first one did. both got our from the same person.

coinsidence??

clinker42 - September 29th, 2009 at 10:42 AM

Fabo

Normally they are just a bolt it up, but seeing you are having issues it really is a check everything. Dave may be able to answer this, what throw

out bearing is used with the Kennedy pressure plates. Some performance and aftermarket pressure plates have a throw out bearing that has a different

length, If this is the case with the Kennedy then if you use a stock throw out bearing it may be a little longer and trying to force the fingers in

further which could be breaking them.

If I was you and not sure on any of the parts that you have, I would buy a complete Exedy kit and install the lot, Unless someone like Dave can help

you out to make sure you have all the correct bits.

cnfabo - September 29th, 2009 at 10:53 AM

whats a exedy kit

clinker42 - September 29th, 2009 at 12:30 PM

http://www.exedy.com.au/

Click Clutch Finder and see if they have one for yours

Really good stuff, locally made, excellent service and support. All of our race cars use Exedy stuff.

They used to be Daiken

matberry - September 29th, 2009 at 07:11 PM

The Kennedy is definately a bolt up.

By memory, I think the clutch depth in the flywheel is 22 mm, can someone confirm?

Does the car ever suffer clutch shudder, this could cause the premature diaphram failure.

cnfabo - September 29th, 2009 at 07:43 PM

my clutch depth in the flywheel measures 20.5mm to 22mm, different ends of flywheel...

the only shudder is the one that just started with my diaphram cracking..but only slightly letting clutch out in first...

dangerous - September 29th, 2009 at 08:13 PM

Factory specification for 200mm flyweels is 21mm....+ or - zero.

Unfortunately this spec is too shallow for the new Kennedy clutches,

which puts the diafragm over centre, thus reducing clamp pressure.

Even worse is, some are cone shaped on the friction surface from new.

The "story" from kennedy is that this is so that the presure of clamp increases with wear.

I have found that even after re-surfacing the shoe,

I still needed about 0.5mm of shims to get the diafragm in a position that was at peak clamp pressure.

If your engine is at the limit of the stage one, in that "over centre" installed height,

correct setting can make it last much longer.

Stepping up to a stage 2 is an extreme next step,

and on most engines, totally unneccesary.

cnfabo - September 29th, 2009 at 09:04 PM

gee whiz,,...

my engine does not have the HP to step up to the stage 2...

so dave are saying that the reason u use the shims is that the preesure plate sits further out to compinsate for the shallow flywheel depth.... gott

ya.... ill try this...

grumble - September 29th, 2009 at 09:18 PM

As clinker says Exedy clutches are good,I haven't had one break a diaphragm in all the time that I have been using them.

HappyDaze - September 29th, 2009 at 09:33 PM

I had a diaphragm crack once. It was cased by too much travel. Ended up setting free-play so that clutch only just dis-engaged, which stopped the

diaphragm from turning inside-out.

Cheers, Greg

cnfabo - September 29th, 2009 at 10:07 PM

greg, so u mean the peedle free play was more then 20-30mm... roughly how much.....

HappyDaze - September 29th, 2009 at 10:12 PM

Probably about 50 mm - just enough travel to release the clutch.