Mendeola S2 - T1 A - Arm Front End

Birdman - October 7th, 2010 at 06:26 PM

OK, so this has got me all hot and sweaty and I thought I should seek input from those more knowledgable than I.

http://mendeolamotors.com/motors/index.php?option=com_content&view=articl...

$3495 spindle to spindle but they can't supply a RHD rack.

I dont want the shocks either so maybe i could get it around $3k. The aussie dollar is 99usc today.

Uses a rabbit rack, is that a mark 1 golf?

Legalities in NSW?

whatcha reckon?

1303Steve - October 7th, 2010 at 06:53 PM

Hi

That is so sexy, it would be a shame to fit a body over it.

Steve

vwo60 - October 7th, 2010 at 07:01 PM

I have been speaking to Kevin at Mendeols motor over the last twelve months with the intention of importing the suspension, front and rear, i have

spoken to a engineer and he can see no reason why you could not engineer it as a modification on your car, it weld's on to a super bug pan only, the

trailing arms are a work of art with the ability to lower the car and run no negitive camber if you wish, you would need to run the coil overs front

and rear to gain the most benifit from the siupension

Birdman - October 7th, 2010 at 07:23 PM

I thought there was a beam version as well?

Ive got a 69 irs and was going to run 944 rear arms.

VW060 we should share shipping?

vlad01 - October 7th, 2010 at 07:55 PM

holy crap thats awesome. wtf! look at the price that has to be a

joke? how come the price is so low for what it is?

that has to be a

joke? how come the price is so low for what it is?

vwo60 - October 8th, 2010 at 10:20 AM

My intention is to purchase what i require when i get back from work oversea's on the 29th of october, i will get one of the car transport companies

to bring it to Australia, i have to work out what the import cost's will be, it would be advisable to get the rear shochs with the front end as well

as you could have a problem with the match of the torsion bars and coils, if you go to the mendeola site you can check out what is exactly available,

you can have the front end built to the exact width that you require, i will be using everything except the brakes and rack and have discussed with

him about my requirements for it to be used as a right hand drive car.

Birdman - October 8th, 2010 at 05:37 PM

I hear what you are saying, I should have elaborated more.

I plan to ditch the rear torsion bars and run a 935 style spring plate. I just dont like their version. Good news about the track I need it to match

those wide 944 arm.

shocks are not a big concern, i just thought i could get a better quality set locally. Lets keep up the dialogue.

vwo60 - October 8th, 2010 at 07:19 PM

The shock's that come with the suspension are high pressure fox shocks that are of very good quality, they have adjustable rebound and compression

damping and these guy know what spring rate will work in this application,as for the rear camber adjuster it works very well with tha ability to

adjust the rear camber and toe very easily, i also have a set of the 944 turbo rear trailing arm's and have discounted there use on this build as

they increase the rear track to much requiring the use of over sized guard's that in my opinion distroy the line's of the car and this is not what i

am after. i have 7" x 17" and 8" x 17" composite rims for the car and will run 2" over guard's on the completed car, i have these on my 60 model

that will be receiving the chassis and will be running the current track of that car, as for the brake's i will run the current brakes that i

engineered and machined for the 60 model, 300mm vented rotor's,billit hub's and 4 spot caliper's

Birdman - October 8th, 2010 at 08:04 PM

that's a good point about the shocks, they will have the rates sorted and thats saves trial and error on my part. I agree the 87 on arms are too wide

and the gaurds you have to run look dreadfull. so 86 arms with aero guards and sorting of the offsets to run the same width wheels. There's enough

camber adjustment in the 944 arms for me and tons of toe with the 935 springplates.

Do they do a beam version???

vwo60 - October 9th, 2010 at 10:04 AM

As far as i know these are made to weld to the super bug pan, but i might be wrong, i think it is eyeball engineering that has one that bolts to a

beam pan but the disign is a compromise as it is made to fit the shape if the beam head

Birdman - October 9th, 2010 at 12:05 PM

Thats is a beam frame horn yes?

vwo60 - October 9th, 2010 at 12:35 PM

Who makes that front end, he told me that it is for a super pan, http://mendeolamotors.com/motors/index.php?option=com_content&view=articl...

this gives you all the option's, it say's that the front end is available for 71 to 75 pan's

Birdman - October 9th, 2010 at 01:04 PM

That is Mendeolas new bolt on / weld on self fixturing kit.

This is what i planned to order, i believe a king pin version is in the works.

Check this thread in the samba if you havent already.

http://www.thesamba.com/vw/forum/viewtopic.php?t=401807&postdays=0&po...

What sort of rack do i have to start looking for?

Does it use beetle spindles?

vwo60 - October 9th, 2010 at 01:27 PM

The spindel's are there own so it has zero scrub radius, but you can use ball joint beetle spindles, i cannot find any mention on there site for that

front end, email kevin he has good understanding of what work's and does not and will make what you require

Birdman - October 15th, 2010 at 07:38 PM

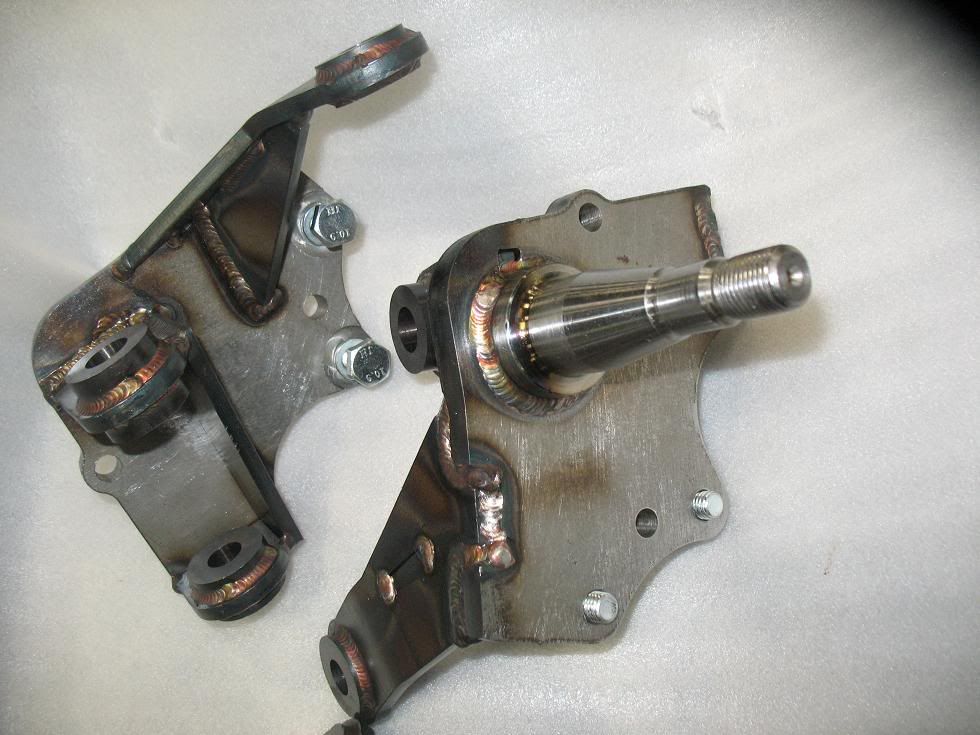

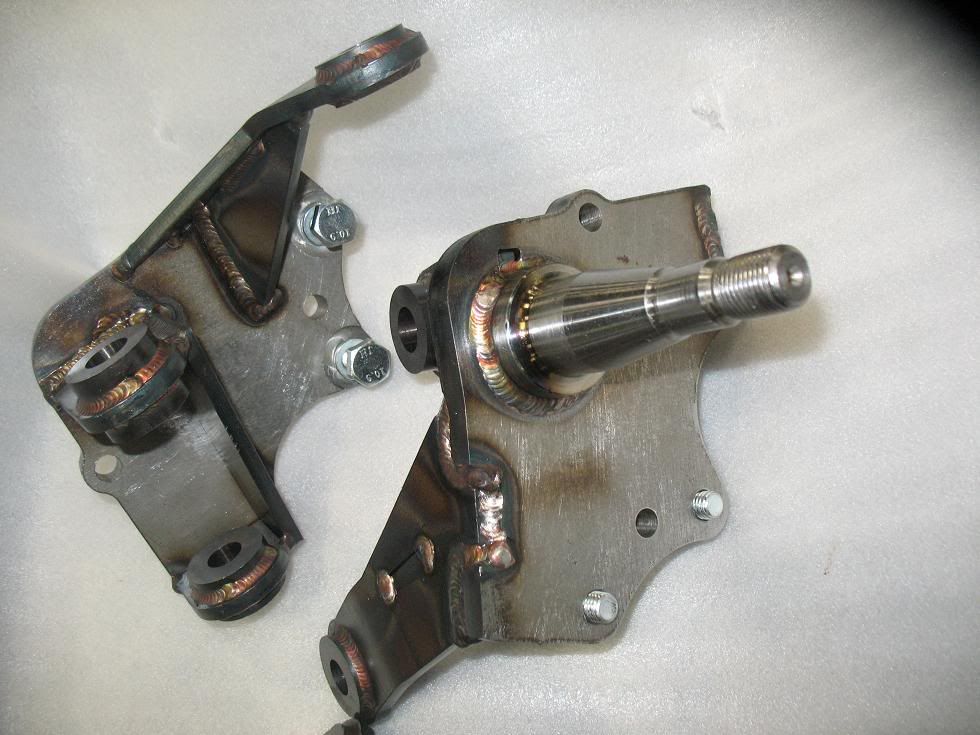

Here's a picture of those spindels. Can anyone confirm what the nsw rta think about welded spindles?

Flintstones - October 15th, 2010 at 10:16 PM

I'm certain that you'd need to have them tested, which will mean that you'd need to buy an extra set so that they can put them through some sort of

engineering test, to the point where they are destroyed, just to see where the breaking point is.

If I remember correctly there was a forum member who did this specifically for the CB dropped spindles in order to obtain engineering approval for his

bug.

Cheers

D

vwo60 - October 16th, 2010 at 10:15 AM

I have already spoke to them about the spindle's and you can use a standard set, it mean's that the wheel offset will have to be adjusted to get the

geometry right

Birdman - October 18th, 2010 at 05:34 PM

| Quote: |

Originally

posted by vwo60

I have already spoke to them about the spindle's and you can use a standard set, it mean's that the wheel offset will have to be adjusted to get the

geometry right

|

Kevin hasn't told me that yet. What offsets does he recommend? et 50 and ???

BTW have you ordered yours because there is one one the way here to oz?

Birdman - June 10th, 2012 at 11:31 PM

I believe someone in queensland has one of these on a hill climb car. I rember seeing some negative comments on another forum but I cant find it.

Does anyone know who has one here is oz?

vwo60 - June 11th, 2012 at 07:33 AM

I spoke to the engineer that i use and he said he would not sign of on it as the spindles are fabricated,

Yogie - June 11th, 2012 at 04:49 PM

As far as I know, Alan at Das Resto Haus has brought one in as he was going to distribute them.

Yogie

vwo60 - June 11th, 2012 at 06:14 PM

The spindles are not a propriority part and to the best of my knowledge you cannot weld or heat a stub axle legally. imagine the engineering cost of

having them approved. i think you would have a better chance getting the red9 front end approved as the pitman arm is the only thing changed from the

standard beetle stub axle and the new one bolts on.

Bizarre - June 11th, 2012 at 07:25 PM

Golde60 got a set of spindles approved

Yes - it cost him some $$$, but was doable

vwo60 - June 11th, 2012 at 07:27 PM

They were not fabricated

Governor - June 11th, 2012 at 09:02 PM

In the picture posted by Birdman they are!

Unless i am the onlyone seeing the stub welded?

Birdman - June 11th, 2012 at 09:21 PM

Yeah those welded spindles are never gonna fly here in oz but they also do the kit with stock spindles. Scrub radius suffers a bit though. Since I'm

in qld for work, looks like a visit to das is in the cards

Governor - June 11th, 2012 at 09:56 PM

| Quote: |

Originally

posted by vwo60

The spindles are not a propriority part and to the best of my knowledge you cannot weld or heat a stub axle legally. imagine the engineering cost of

having them approved. i think you would have a better chance getting the red9 front end approved as the pitman arm is the only thing changed from the

standard beetle stub axle and the new one bolts on.

|

I have heard you cant get the Red9 one engineered anymore?

I would check before buying

vwo60 - June 12th, 2012 at 08:25 AM

I was refering to the spindles that Golde60 had tested, they were forged dropped spindles not the welded spindles on the Mendeola. you would be able

to take care of the increase in scrub radius buy getting the correct offset wheels. you just need to talk to a good engineer before you buy the front

end, he will tell you if he will approve it or not, i spoke to both Red9 and Mendeola and Red9 was the only one that could supply the welding code for

the front end, i do not think that Mendola has one as they did not supply it when asked.

that has to be a

joke? how come the price is so low for what it is?

that has to be a

joke? how come the price is so low for what it is?