| [ Total Views: 228345 | Total Replies: 437 | Thread Id: 75812 ] |

| Pages: 1 .. 12 13 14 15 |

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on October 16th, 2012 at 07:53 AM |

|

|

Time for an update...

I took the car on track and although it was struggling with the ignition side of things, at 1.2Bar boost, it was going OK. GPS'd it at 130mph with

loads more to go but then I blew the intercooler pipe and sudden loss of power along with clouds of smoke out of the back end! You should be able to

spot the hole in the turbo to chargecooler pipe in the pic above..

I was hoping for an easy fix (and excuse to upgrade to silicone pipe), worst case it may have been the turbo but I have a spare one of those. I've

also got some newage coilpacks on the way to upgrade from the old ones which degrade quite badly with age.

The parts arrived so I got cracking...

New silicone pipe bought to replace the holed one, this should be good for much higher boost too.

Unfortunately after swapping the pipe and the turbo the oil filter seal blew dumping oil all over the garage floor. I tried another filter and the

same thing happened. Googling pointed towards the relief valve on the oil pump being jammed shut.

After fitting another oil pump the engine seems to run ok with normal oil pressure, albeit chucking out a lot of smoke from the oil it has in the

intake! The old oil pump relief valve was jammed solid almost closed, even with the pump off the car I can't move it!

Changing the pump meant stripping the rear panels off the car as well as cambelt etc etc so now I had to refit and seal things back up. I'm also

using the opportunity of it being up in the air to convert to newage coilpacks which will also help it run better on boost. I made new looms for them

tonight as a change and will bypass the old ignitor as the new coilpacks have built in igniters..

The early optimism ended in disappointment, I went for a drive and it was gutless and the oil screen didn't improve. I got a compression tester and

one of the cylinders showed no compression at all. There was nothing to do but pull the engine and get the head off to assess...

You can just about make out some damage to the top of the cylinder wall

and if you look carefully you can see that the ring is distorted, I'm assuming that the piston ring land has failed underneath...

So, after contemplating my options and considering where I want to be realistically with this car I've decided to rebuild it with a 2.5 sti bottom

end. It's a semi-closed deck block but they are good for about 450bhp, I think that should be enough in a bug!! I was also considering a forged 2 or

2.1 stroker but for drivability the torque of a 2.5 wins for me. I'll upgrade the externals to allow greater power at a later date.

|

|

|

vlad01 vlad01

Compulsive Aussie Vee Dubber

Posts: 4270

Threads: 109

Registered: June 3rd, 2010

Member Is Offline

Location: Kyneton, VIC

Theme: UltimaBB Pro Blue ( Default )

Mood: Side ways

|

| posted on October 17th, 2012 at 02:24 PM |

|

|

I heard this is really common problem with the turbo models, the ring land collapses.

71 notchback,

Past owner of, 70 NB, 73 SB and 72 FB TLE |

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on October 28th, 2012 at 05:35 AM |

|

|

With the old block unusable in its state I decided to bring the final plan forwards... So, with a bit of hunting I found a 'rebuilt' 2.5l STI

shortblock on ebay.

Final build will consist of 2.5 sti upgraded with forged pistons, V3/V4 sti heads which I will rebuild, upgrade one of my turbos to td05-20g, new

bigger injectors, new oil modine, sump baffle plate and probably some other supporting mods being topped off with a remap on an ESL daughterboard,

probably by Bob Rawle when he visits API.

The shortblock as I received it. With some thought I decided that I will always feel uneasy about the stock pistons as they haven't got a very good

reputation. After a chat with David at API (well respeced Impreza engine builders only 5 miles away from my house!) I decided to go with some forged

pistons. Supertechs have a good reputation for not being rattly like most and API have experience of them so that's the way I have gone. The stock

rods are good for 450bhp ish as they are the latest spec ones. My goal is a good 400bhp.

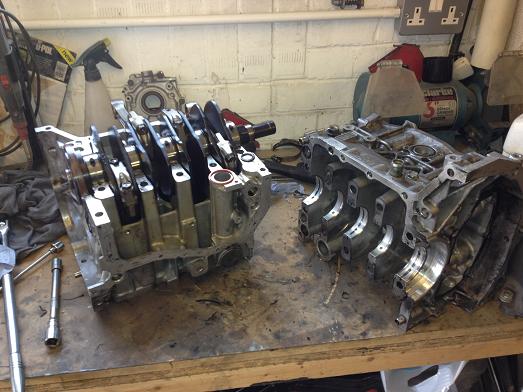

Time to split the block as the cylinders needed honing to fit the pistons. It would also give me a good opportunity to inspect the 'rebuild'.

The big end bearings were supposedly new! I've replaced them with ACL bearings

Main bearing clearances checked with plastigage, they are all good, as are the bearings. Luckily this is the better nitrided crank too..

Block halves back from API after being honed, they have been done to 3.8thou piston clearance.

Here's the first supertech piston, I've gapped the rings to specs..

I'm quite enjoying this engine building lark, this is my first attempt!!

|

|

|

vlad01 vlad01

Compulsive Aussie Vee Dubber

Posts: 4270

Threads: 109

Registered: June 3rd, 2010

Member Is Offline

Location: Kyneton, VIC

Theme: UltimaBB Pro Blue ( Default )

Mood: Side ways

|

| posted on October 29th, 2012 at 10:09 PM |

|

|

umm? something seems wrong with that wear pattern on the big ends.

looks like if might be a problem with bearing crush, I could be wrong though? have the rods been re-sized correctly if at all? They very well might

be new bearing but big ends incorrectly set and ended up with this damage.

I would use an inside micrometer to check the big end bore see if its in spec, fully torqued of course before considering the bearings.

do you have a workshop manual for these engines? better yet, get a workshop to check it out for you that has experience with these engines.

good luck with your build.

71 notchback,

Past owner of, 70 NB, 73 SB and 72 FB TLE |

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on October 30th, 2012 at 04:41 AM |

|

|

That was the only one showing wear like that, the others were more usual wear patterns. I'm not even convinced those bearings were with the rods to

get that wear which is another reason I went with new parts. The rods and crank were both checked over by the local builders and are fine. I'm

working from a factory workshop manual too

|

|

|

Jak Rizzo Jak Rizzo

Insano Dub Head

Posts: 837

Threads: 67

Registered: April 26th, 2004

Member Is Offline

Location: Central Coast

Theme: UltimaBB Pro Blue ( Default )

Mood: Pastizzi eating

|

| posted on October 30th, 2012 at 04:13 PM |

|

|

Hi Rich,

Thats exactly what my engine did way back in January of 2005, broken ringlands after a track day. I only had mine rebuilt (nothing like yours) back to

factory specs albeit with 20thou oversized pistons, the little engine has now done 223'000 klms

Your car is going to fly !!!

Jak

|

|

|

vlad01 vlad01

Compulsive Aussie Vee Dubber

Posts: 4270

Threads: 109

Registered: June 3rd, 2010

Member Is Offline

Location: Kyneton, VIC

Theme: UltimaBB Pro Blue ( Default )

Mood: Side ways

|

| posted on October 30th, 2012 at 05:29 PM |

|

|

| Quote: | Originally

posted by ricola

That was the only one showing wear like that, the others were more usual wear patterns. I'm not even convinced those bearings were with the rods to

get that wear which is another reason I went with new parts. The rods and crank were both checked over by the local builders and are fine. I'm

working from a factory workshop manual too

|

awesome

71 notchback,

Past owner of, 70 NB, 73 SB and 72 FB TLE |

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on November 14th, 2012 at 08:47 AM |

|

|

Block ready to go back together with new seals, note tape on rod little ends to avoid the risk of scratching the bores on assembly.

All torqued and sealed up..

first piston going in...

all pistons in, you have to make sure they are all orientated correctly as well as positioning the piston ring gaps too

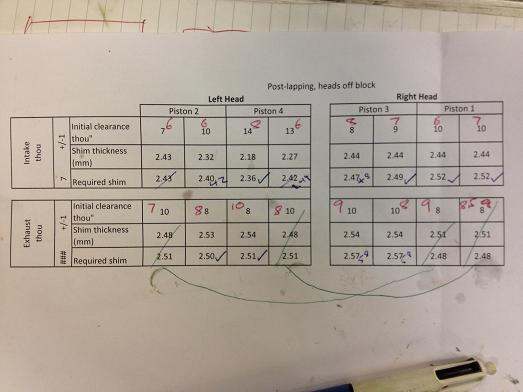

V4 STI cylinder heads stripped for refresh. All valves cleaned up, re-lapped in to the heads and then ready for first lash measurement. These heads

use under-bucket solid shims which come in various different thicknesses and you change shims to get the correct clearances.

I knocked off any sharp edges in the combustion chamber to help avoid detonation, this can sometimes be an issue when fitting 2l heads on a 2.5 block

due to the slight cylinder diameter mismatch

You can see one of the shims sitting on top of a valve.

Lots of measuring!

and measuring, then swapping shims

Ready to go on the engine!

ARP head studs fitted to give better head gasket clamping under boost

Back to a longblock! I had to fit the cambelt and re-check the valve clearances as the cam loading can change things. Luckily only one shim needed

swapping after assembly.

V3/4 cam covers were cleaned up and treated to some VHT wrinkle paint, note one on left hadn't had any heat applied ot get the wrinkle effect started

yet.

Coolant manifold needs modifying to clear the central 2.5l breather pipe.

Now I just have to decide what turbo and injectors to go with!

|

|

|

Flintstones Flintstones

Custom Title Time!

Posts: 1077

Threads: 69

Registered: August 27th, 2002

Member Is Offline

Location: Sydney

Theme: UltimaBB Psyche Blue

|

| posted on November 14th, 2012 at 10:56 PM |

|

|

| Quote: | Originally

posted by ricola

Now I just have to decide what turbo and injectors to go with!

|

The biggest ones you can fit of course

Cheers

D

|

|

|

1303Steve 1303Steve

A.k.a.: Steve Carter

Scirocco Rare

Posts: 8650

Threads: 564

Registered: August 27th, 2002

Member Is Offline

Location: Sydney, NSW

Theme: UltimaBB Pro Blue ( Default )

Mood: Parrot Heading

|

| posted on November 15th, 2012 at 06:06 AM |

|

|

Hi Rich

Excellent work as usual. Lucky you have a drive line that can handle this sort of power.

Are you going to stick with the VF series turbos?

Steve

|

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on November 16th, 2012 at 05:18 AM |

|

|

I'm going to have to go to about 730cc/min injectors, 550s seem to max out at 400-420bhp and I want a bit more than that, as long as I go with

un-modified ones I should still get decent idle control. Turbo is looking like a scooby clinic sc46, it's a billet garret ball bearing direct fit and

it can do up to about 500bhp. People seem to rave about them and they deliver the power without having to run excessively high boost levels.

Definitely happy I went with the G50 and 930 CVs now!! Have a feeling I'll end up having to get a KEP clutch after the running in period though,

possibly a re-think on the chargecooler to a better spec too, it never ends..

|

|

|

1303Steve 1303Steve

A.k.a.: Steve Carter

Scirocco Rare

Posts: 8650

Threads: 564

Registered: August 27th, 2002

Member Is Offline

Location: Sydney, NSW

Theme: UltimaBB Pro Blue ( Default )

Mood: Parrot Heading

|

| posted on November 16th, 2012 at 08:10 AM |

|

|

Hi Rich

That's really going to mess up your hair with the top down.

How have you found the G50 ratios? I love mine, 1st gear is amazing.

Steve

|

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on November 17th, 2012 at 08:15 AM |

|

|

Gearing is great for a road car which is what this is primarily. I guess with the new engine it will probably be well matched for the strip too, it

was a bit long for the old engine.

Have you been driving yours much? Are you happy with the grimmspeed oil separator? I'm probably going to fabricate a group N style sump too while

it's all apart. Pondering options about intake too, I could lift the intake manifold and run a bigger bore intake direct with less restrictions and

use the heat isolators. Think I have to do this in stages or it will never get back together!!

|

|

|

1303Steve 1303Steve

A.k.a.: Steve Carter

Scirocco Rare

Posts: 8650

Threads: 564

Registered: August 27th, 2002

Member Is Offline

Location: Sydney, NSW

Theme: UltimaBB Pro Blue ( Default )

Mood: Parrot Heading

|

| posted on November 18th, 2012 at 08:27 PM |

|

|

Hi Rich

I have to pull my bug apart soon to fix gearbox noise but I just want to keep driving it, its so much fun and makes a heavy 1303 feel like it weighs

nothing.

I will have look in my inlet tract for any oil when I pull the car down, my local Subaru guy highly praised the Grimmspeed oil separator.

I fitted my bigger bore inlet without lifting the manifold after I cut it up a bit in place.

Steve

|

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on December 19th, 2012 at 02:00 AM |

|

|

As it was apart, I've gone with an RCM oil baffle plate to help avoid surge.

Coolant manifold TIG'd back together, I deleted the normal heater pipe as I found as it's new role as a manual bleed I never actually got any air

out of it and this way I have more space if I decide to go with a direct turbo intake under the intake manifold

Parts to make up a large bore exhaust crosspipe. I had already ported the stock item but it was still very restrictive. Grimmspeed sell one but I

thought I may as well make one myself

tacked together and now ready for finish welding

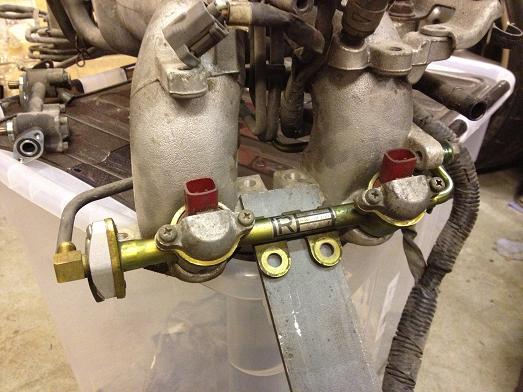

Bought a set of 740cc/min Nismo phase 2 injectors, the phase 2 fuel rail can apparently be fettled to fit the phase 1 so I prefer this to using

adapter rings. Note mounting tabs are on the wrong side of the rail, I might make an adapter out of a piece of 5mm plate like this...

Shiney go-faster bits have arrived! Scooby Clinic SC46 billet turbo based on a Garrett ball bearing core, good for 460bhp on V-power and an Aeromotive

fuel pressure regulator to go with an uprated fuel pump and parallel fuel rail conversion.

I've had to make a new intake to suit the front entry turbo, I could have gone under the inlet manifold but it would have lengthened the intake by a

fair bit.

Engine back in the car and fired up for the first time, it sounds good! This is on the old map & injectors, mainly to get the oil system primed

and make sure everything on the engine is good.

http://www.youtube.com/embed/rBhGtrmA_TE

More bits arriving soon are:

oil breather catch tank

inlet manifold thermal insulating spacers

HRC 310 lpm fuel pump

Then I'll be ready for the re-map!

|

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on January 21st, 2013 at 04:47 AM |

|

|

Oil breather tank hanging off the back, there wasn't much space anywhere else! I also made up a new bracket which supports both the oil pressure

senders and the Aeromotive fuel pressure regulator

I was advised by my mapper that the old Legacy chargecooler would be limiting my performance so it was time to upgrade. I considered an air/air using

enlarged ducts built into the rear wings but I don't really think I've got space for it. I eventually found a very good thread on using a

frozenboost type 14 chargecooler. It is apparently good for 700 CFM / 600 BHP and one person reported that when running 22psi he sees a maximum of 10

degrees above ambiant but normally only about 5 degrees which is pretty efficient in my book!

2 weeks later and this arrived in the post:

I wasn't satisfied that the system would be working well without trapping air so I decided to drill and tap a bleed point. I drilled on a tilted

table on my pillar drill very cautiously as I didn't want to wreck the core! Turns out the end tank isn't completely solid as it looks but cast and

it hollowed out a bit with extra clearance to the air core so wasn't too bad to do. A small M6 bolt with O-ring will serve as a manual bleed.

The turbo pipe I made up to join to the chargecooler inlet. 2" going up to 2 1/2" with a fitting for the reciculating dump valve. I had off-cuts of

stainless lying around from old exhaust system build so I'm sure it will do the job fine. The 2 1/2" end joins to the chargecooler with a 3" to 2

1/2" silicone reducer elbow.

You can see a strap supporting the weight of the chargecooler off the frame above via some rubber washers to isolate it. Just in sight is a filler cap

from a Suzuki motorbike which has the correct size fittings for the water pipes.

Finally I had to some some re-shaping of the bulkead panel to clear the end tank.

Now it's ready for the running in map on an ESL daughterboard, just hope the recent snow doesn't delay things...

|

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on January 25th, 2013 at 05:48 AM |

|

|

Update from the mapping session..

The engine runs really well, nice and smooth with very good early turbo spool. By the end of the run the new chargecooler was still stone cold so all

in fairly happy! The downside is that the clutch can't take the torque, we were limited to just under 1 bar boost pressure which is fine for running

in but I'll have to sort out an uprated one before getting the final map up to full boost done.

|

|

|

vlad01 vlad01

Compulsive Aussie Vee Dubber

Posts: 4270

Threads: 109

Registered: June 3rd, 2010

Member Is Offline

Location: Kyneton, VIC

Theme: UltimaBB Pro Blue ( Default )

Mood: Side ways

|

| posted on January 29th, 2013 at 02:42 PM |

|

|

wow this great.

I read you blocked off the heater ports?

As I understand it the heater was also part of the thermostat and temp control, I also hear that it must be looped if no heater is being used so the

engine temp remain stable as intended by the factory.

I am no expert on the matter but many experts stress this as this one cooling system difference that sets suby apart from from most cars.

have you heard about this too?

71 notchback,

Past owner of, 70 NB, 73 SB and 72 FB TLE |

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on January 30th, 2013 at 07:47 AM |

|

|

If you look back you'll see that I have completely reworked the system so that the thermostat is on the outlet, not the return. This works much

better with the additional coolant volume of our conversions. I also have ZERO bleeding hassles, from dry I literally just fill up with coolant at the

header tank and it's done..

|

|

|

vlad01 vlad01

Compulsive Aussie Vee Dubber

Posts: 4270

Threads: 109

Registered: June 3rd, 2010

Member Is Offline

Location: Kyneton, VIC

Theme: UltimaBB Pro Blue ( Default )

Mood: Side ways

|

| posted on January 30th, 2013 at 09:31 AM |

|

|

fair enough but i think thats just trying to out smart the engineers who designed the engine and its cooling system.

its might work ok but the internal thermal dissipation will be totally different from stock setup and may effect the engine long term.

only one way to find out, suck it and see.

71 notchback,

Past owner of, 70 NB, 73 SB and 72 FB TLE |

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on January 31st, 2013 at 05:41 AM |

|

|

Well I am an engineer and we have a totally different set up to when the engine was in the subaru. The extra volume of the long radiator lines totally

messes with the original thermostat's ability to maintain a stable temperature, particularly in cooler climates. My system works great, so I'm

happy!

|

|

|

ancientbugger ancientbugger

Custom Title Time!

Posts: 1986

Threads: 191

Registered: March 24th, 2004

Member Is Offline

Location: sunshine coast

Theme: UltimaBB Pro Yellow

|

| posted on March 3rd, 2013 at 05:30 PM |

|

|

Just sat here on a very rainy afternoon and read all this, 'impressed' is just not a good enough word. Brilliant work. Only one comment to make

though - a video of it please on Youtube

|

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on March 4th, 2013 at 02:11 AM |

|

|

Cheers... It's in bits at the moment, I ended up having to go with an upgraded clutch so bit the bullet and fitted a KEP stage 1 good for about

550ftlbs. There are a few videos on youtube but I really need to do an up to date tour around with maybe some driving...

|

|

|

badvw68 badvw68

Casual Dubber

Posts: 40

Threads: 3

Registered: November 3rd, 2005

Member Is Offline

Location: Southern Illinois, USA

Theme: UltimaBB Pro Blue ( Default )

|

| posted on March 8th, 2013 at 03:18 PM |

|

|

Looks great Rich! Too bad you have had all the issues you've had...

We are all looking forward to some in action videos...

Do you mind, could you post a few pics of below of how you are mounting you rear bumper?

Thanks,

Alden

|

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on March 9th, 2013 at 06:14 AM |

|

|

That should be fairly obvious how I did it?

|

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on March 9th, 2013 at 07:12 AM |

|

|

Bit of an update:

I made up a new bulkhead panel to properly clear the new chargecooler

New stage 1 KEP clutch, this is rated to 550ft lbs torque so fine for my target level of about 450..

The release bearings changed to include a plastic liner, this meant that I needed to buy a new bearing guide tube from Porsche..

While the chargecooler was off again I thought I would take the opportunity to improve the mounting and filling system. Here is a new support bracket

using a locost type suspension rubber bushing I had lying around

New filler neck welded to the chargecooler makes the pipework much neater and is obviously much easier to bleed and keep full. The filler neck was

decent and came from Mishimoto, most others were pretty flimsy pressed items.

All fitted again, the chargecooler is much better mounted and easier to fill now.

|

|

|

Flintstones Flintstones

Custom Title Time!

Posts: 1077

Threads: 69

Registered: August 27th, 2002

Member Is Offline

Location: Sydney

Theme: UltimaBB Psyche Blue

|

| posted on March 9th, 2013 at 08:58 PM |

|

|

Just so neat, Rich.

Cheers

D

|

|

|

surfbeetle surfbeetle

Casual Dubber

Posts: 30

Threads: 1

Registered: February 24th, 2007

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on March 10th, 2013 at 05:29 AM |

|

|

| Quote: | Originally

posted by ricola

That should be fairly obvious how I did it?

|

Yes it is and it's great. I will be borrowing this idea for my rear bumper. Thank you for the photos.

|

|

|

1303Steve 1303Steve

A.k.a.: Steve Carter

Scirocco Rare

Posts: 8650

Threads: 564

Registered: August 27th, 2002

Member Is Offline

Location: Sydney, NSW

Theme: UltimaBB Pro Blue ( Default )

Mood: Parrot Heading

|

| posted on March 10th, 2013 at 08:44 AM |

|

|

Hi Rich

Did you find the KEP pressure plate a lot lighter in weight than the Porsche one? It should speed up engine response.

Steve

|

|

|

ricola ricola

Wolfsburg Wizard

Posts: 437

Threads: 9

Registered: February 5th, 2003

Member Is Offline

Location: UK

Theme: UltimaBB Pro Blue ( Default )

|

| posted on March 10th, 2013 at 07:38 PM |

|

|

Steve: yes the KEP is much lighter, I didn't bother to weigh it as I've seen them quoted quite a lot on Porsche forums. TBH the engine spun up

quickly before but as now I get power to the wheels rather than burning up the clutch it isn't a proper back to back comparison.

|

|

|

| Pages: 1 .. 12 13 14 15 |