| [ Total Views: 7651 | Total Replies: 61 | Thread Id: 75978 ] |

| Pages: 1 2 3 |

|

|

fullnoise3 fullnoise3

Learner Dubber

Posts: 10

Threads: 2

Registered: April 15th, 2009

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on April 17th, 2009 at 09:04 PM |

|

|

Cam is short for Cameron. That's all I know.

I should've asked an easier question like.... I don't know. What's the meaning of life?

Thanks for your detailed response Dr Dave, Daimo, Col, Michael Jackson and everyone else. Also I'd like to thank God (For the time off over Easter

which allowed me contemplate the VW engine religion).

Thanks Jak, for the moral support.

I haven't sent my VW lifters off to be reground yet.

I emailed the head place about the machining and stupidly half expected a response. You have to lob up and dump the heads on their counter.

From memory I've heard that the k8 has a harmonic problem or something odd like that. Surely, enough people have used them over the years to confirm

they're pretty safe. Or is the problem the build quality? Are they made in China now or something?

What about a WebCam 86b?

I'm leaning towards a K10 now. Richard Holzl says he did a back to back comparison with the W130 and K10. The result being that he swears by rocker

cams and thinks they're far more efficient.

Can you really get 530 lift out of 112mm long valves? I'll pull the heads apart tomorrow and have a gander.

CYA CT

|

|

|

Cam Cam

Custom Title Time!

Posts: 1535

Threads: 187

Registered: August 27th, 2002

Member Is Offline

Location: Melbourne

Theme: UltimaBB Pro Blue ( Default )

Mood: addicted

|

| posted on April 17th, 2009 at 11:48 PM |

|

|

You could of also started a topic on peace in the middle east...

Just for an after dinner, light intellectual load thread.

Camshafts, geez!

|

|

|

dangerous dangerous

A.k.a.: Dave Butler Muffin Man

23 Windows of Awesome

Posts: 5901

Threads: 178

Registered: January 6th, 2005

Member Is Offline

Location: Gold Coast

Theme: UltimaBB Pro Blue ( Default )

Mood: 591

|

| posted on April 18th, 2009 at 06:10 AM |

|

|

| Quote: | Originally

posted by colin

Sorry Dave have to respectifully disagree.

Used a K8 cam for over 3years of racing no probs at all.

Cheers Col

|

That's cool Colin.

I think most were the berg's own version.

I can not confirm all of them, but most.

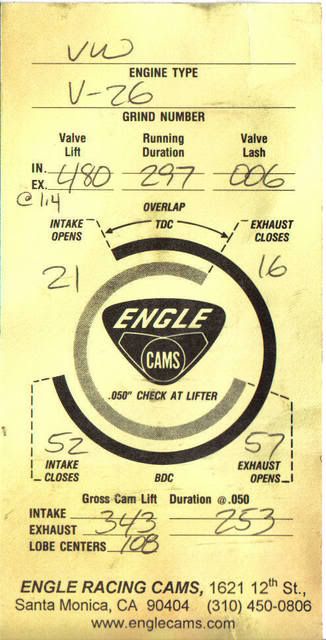

Chris Fabian, if it is a CB one (or genuine engle as Col used) you should try the 1.4s.

If it is a GB310 cam then keep your 1.25s and tighten up your tappets to zero clearance.

But you must have room for spring bind and retainer-to-gude clearance.

Every one using any grind with cromoly pushrods should use zero clearance when cold.

Because there is ony 4 degrees diff between the K8 and V26,

I woul dtend to go more toward the V26 with a larger rocker(berg 1.4s, normal brand 1.5s etc).

All this assumes the same heads...but did you say you were changing those CT?

| Quote: | Originally

posted by westi

That's mad Alan.

|

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on April 18th, 2009 at 09:01 AM |

|

|

| Quote: | Originally

posted by Craig Torrens

Would the Tighe 149A be similiar to the V26 ??

|

CT .........can you tell us a bit more of what youre after as far as drivability and rpm range you like to run in? (just for interests sake after all

this) I'm lifting over .500' with the 1.45 rockers.....i'll get the books out and see what numbers it was making with the 1.54's as i did run out

of travel then (although actual lift was close to 1.7:1 at the valve)

what i like about the V26 is ability to drive it from 1500 rpm right thru to 6800rpm (whilst still making GOOD POWER THERE), accepting full throttle

from 2250rpm even with 48s on the 1776cc...........after having had bigger cams where feeding in the throttle was necessary, it's nice to concentrate

on other things.

How did you find it when you drove it Matty B?

i'll get the camera out again and see if i can demonstrate in some footage (again just for interests sake)

all very interseting, will be great to hear results and thoughts when your done no matter what your choice

i still don't know poop

|

|

|

matberry matberry

Super Moderator

Go hard or go home

Posts: 8114

Threads: 134

Registered: March 7th, 2006

Member Is Offline

Location: Cooroy Qld

Theme: UltimaBB Pro Blue

Mood: enjoying waving at all my Kombi buddies from my T3

|

| posted on April 18th, 2009 at 10:22 AM |

|

|

| Quote: | Originally

posted by hellbugged

How did you find it when you drove it Matty B?

i still don't know poop

|

The package you have there Daimo is brilliant.

It's drivability is smooth as, like a stock (dare I say it) late model ricer engine, power delivery is also very smooth being very even accross the

rev range. With well over 100 hp from this small engine and temperatures well within normal range,I'd drive your car to Perth, race it and be

confident it was still going to get me home. Certainly something to be proud of. Mind you, a bit more seat time would be nice to really have a go.

It proves it's the combination of parts and not any one or two components that will give this type of package. Any one can throw together parts. It

takes a true artist to get an engine to deliver GOOD power, be driveable AND reliable.

Who is this Poop guy?

Matt Berry Motorsports...air cooled advice, repairs and mods Ph 0408 704 662

OFF-ROAD,CIRCUIT,DRAG,STREET,ENDURANCE

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on April 19th, 2009 at 07:33 AM |

|

|

....you're a funny man Matt. ....you're a funny man Matt.

poop's vid........

http://www.youtube.com/watch?v=MYe5uZwxLgk

oh CT, only girls wear ipods instead of listening to dual carbs  ..........and if you end up with a V26 and don't like it..... i'll remove all these posts so it appears it's all Doc DB's fault ..........and if you end up with a V26 and don't like it..... i'll remove all these posts so it appears it's all Doc DB's fault

hmmm straight cuts..........?

got a rotary grinder and spare couple of days?.......i'll send you down the burrs and templates to do "the job" on those heads

|

|

|

55slug 55slug

Seriously Crusin Dubber

Posts: 169

Threads: 22

Registered: July 2nd, 2006

Member Is Offline

Location: NZ

Theme: UltimaBB Psyche Red

|

| posted on April 19th, 2009 at 06:51 PM |

|

|

Ill put a vote in for the cb k8 equivalent, .530" plus a bit lift is doable with a stock length valve with bugpack 4046 springs (thinner coil

diameter - more lift to bind) and I used remmelle alu retainers, ti would probably allow more lift if required. I never found it on and off the cam,

all go from idle to 7500.

|

|

|

fullnoise3 fullnoise3

Learner Dubber

Posts: 10

Threads: 2

Registered: April 15th, 2009

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on April 20th, 2009 at 08:43 AM |

|

|

Maths.

I did a lot of thinking over the weekend. Stuff that would take others minutes. For this stuff my degree in advertising an marketing is bloody

useless.

While the VZ26 sounds very tempting and a good argument has been presented and endorsed, Plan E is currently to go with the K8. I mentioned Plan F

(below) to Jak on Sunday and he was disappointed. So to prevent him turning up at my house with K8 themed cheer leaders I've got no choice.

Whatever the plan I need to get the heads machined for more lift.

Now for the thinking stuff. Perhaps Captain Poop and Dr Dave can help with a red pen here.

Desired valve lift 0.530 = 13.46mm

0.090 recommended minimum distance from full lift to coil bind = 2.28mm

Total. I need the valve springs to compress a minimum of 15.74mm from the installed height.

With the valve springs removed I measured the distance between the retainers and valve guide. The minimum was 16.4mm and the maximum was 17.0mm. So

the new lift won't have the retainers hitting the guides. Good.

Then I measured the distance from the top of the guide to where the springs seat. Min 15.8mm and Max 16.mm.

I think this is the figure I'll give a machine shop so the brief will be to machine the spring seat to say 17.5mm below the top of the valve

guide.

The retainers are 8mm from the bottom to the top lip. Add this to the other two measurment miniums 15.8 + 16.4 and I get a minimum installed valve

spring height of 40.2mm.

I put the valve springs and retainer in a vice and squashed them until they went stiffer in such a way that wasn't progressive. The compressed height

was 25mm bit including the retainer.

The springs compress 15.2mm and I need them to compress 15.74. So I'm about 0.5mm too short. Should I get 1.5mm machined from where the valve springs

seat and then use shimms as required?

Does that sound correct?

The idea about using the thinner coil bugpak springs is a good one too.

Plan F. If I can't get the cam and lifters in time I'm going to bung the W130 back in with 1.25 rockers. With 0.419 lift at the cam these will give

around 0.523 at the valve which should bring the W130 closer to K10 specs.

CYA CT

|

|

|

Jak Rizzo Jak Rizzo

Insano Dub Head

Posts: 837

Threads: 67

Registered: April 26th, 2004

Member Is Offline

Location: Central Coast

Theme: UltimaBB Pro Blue ( Default )

Mood: Pastizzi eating

|

| posted on April 20th, 2009 at 08:48 AM |

|

|

give me a "K"

Give me an "8"

What do u get?

happy jako my habib!

|

|

|

fullnoise fullnoise

Fahrvergnugen

Posts: 964

Threads: 103

Registered: September 21st, 2002

Member Is Offline

Location: Sydney

Theme: UltimaBB Pro Blue ( Default )

Mood: Middle of the road.

|

| posted on April 20th, 2009 at 08:57 AM |

|

|

That fullnoise3 bloke is an idiot. Then there's that Jak bloke..... don't get me started on him.

esratrams

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on April 20th, 2009 at 09:29 AM |

|

|

Maths..........i've got a headache already!

DB will have the answers.........

..i'm not sure who will be doing your heads CT, but Ben Durie did plenty of work on mine (4 angle seat cut and shimming/ travels/binds

etc).........HE KNOWS HIS STUFF in this area and is willing to take the time and effort required!.........without you needing to prompt on the numbers

aside from providing the cam card and lift

been a while since i've had those calcs etc in my head so i wont comment too much and get it wrong. DB has spent a life time doing those numbers and

is the response to take note of (not that we don't all know that already).....

sorry i'll insert more more poop here ....i'd be very wary of

cutting the spring seats ESPECIALLY on the intake and definately not if the bumps in the inlet ports have been touched in any way during the

porting...........working off actual measured lift numbers at the valve is the only way to go for me..........triple springs provide at same height

more travel from memory...........must run at least one .015" shimm can run as little as 0.100" travel over lift (0.060" if you're very brave and

very sure it's all measured perfect)............check the lifter to bore clearence with the new changes. i had my lifters machined under the head to

provide assured clearence.......consider doing the cut between oil groves now you're going to ratio rockers...... ....i'd be very wary of

cutting the spring seats ESPECIALLY on the intake and definately not if the bumps in the inlet ports have been touched in any way during the

porting...........working off actual measured lift numbers at the valve is the only way to go for me..........triple springs provide at same height

more travel from memory...........must run at least one .015" shimm can run as little as 0.100" travel over lift (0.060" if you're very brave and

very sure it's all measured perfect)............check the lifter to bore clearence with the new changes. i had my lifters machined under the head to

provide assured clearence.......consider doing the cut between oil groves now you're going to ratio rockers......

port those suckers!.........run the exhaust ports out to 1mm off the watercooler kombi gasket size to keep some low end tourque through airflow

speed.......shape those chambers good and proper! (IVE GOT THE TEMPLATES IF YOU"VE GOT THE NERVE)........

if you need anything in a hurry, i'll gladly open the conveyer belt from bergs for you.......it's really quick, brings stuff over with in the week,

it could be here before this weekend (cams, modified lifters hint HINT ).......i've got new berg standard lifters, new set molly pushrods (unasembled so can make to size) helical adjustable timing cam gears, lash caps

and literally bags of valve shimms etc here if the need arises........also GOOD cam lube and the tool to run outer spring only and install inners

after break in.....happy to help however i can with all this stuff if or when the need arises to keep you on target , PLEASE DONT HESITATE to ask ).......i've got new berg standard lifters, new set molly pushrods (unasembled so can make to size) helical adjustable timing cam gears, lash caps

and literally bags of valve shimms etc here if the need arises........also GOOD cam lube and the tool to run outer spring only and install inners

after break in.....happy to help however i can with all this stuff if or when the need arises to keep you on target , PLEASE DONT HESITATE to ask

this is all exciting and stimulating tho ......i'll put the kettle on and wait for D.B to spread more of his wisdom

|

|

|

dangerous dangerous

A.k.a.: Dave Butler Muffin Man

23 Windows of Awesome

Posts: 5901

Threads: 178

Registered: January 6th, 2005

Member Is Offline

Location: Gold Coast

Theme: UltimaBB Pro Blue ( Default )

Mood: 591

|

| posted on April 20th, 2009 at 02:02 PM |

|

|

ooh, cuppa sounds good!

Daimo has everything that you need to do above.

Yes, you must check the actual lift at the valve before doing any maths....well definitely before ANY machining.

There is SO much variance in rockers and the ACTUAL ratio that you have because of varying geometry,

that you absolutely have to see what you have first. (what brand rockers?)

Sounds like your retainer to guide clearance is close enough to start the process,

so the next step will be to use a light spring, and check that this is true!!

If everything clears, and your geometry is now correct,

then see if the springs will fit...no shims for now.

The reason foir this

is that once your actual springs are fitted, you will lose some lift (I lose about .030" with my big springs).

This will give you some additional room.

Try to avoid all the maths if you can.

It just gives room for error.

Yes by all means calculate what you can, before you start,

but aways check the actual real figures that are there.

Without seeing your actual situation,

I would say that I would try for a different spring and/or retainer before ever machining the spring seat.

In fact I would even run it without a spring shim if I had to, rather than make the head thin under the spring.

There are quite a few different retainers out there, and springs as you said,

so I would go that route,

and you can always pick up a little room by facing a valve or the retainer's spring surface.

.060 or 1.5 mm is a good number to aim for for the extra room to bind, as Daimo suggested,

but I have run as close as .030 on my own engine, in the search for more spring tension.

But be aware, if your combo gets a "loss of valve control",(as a K8 can) it will just do damage.

So...

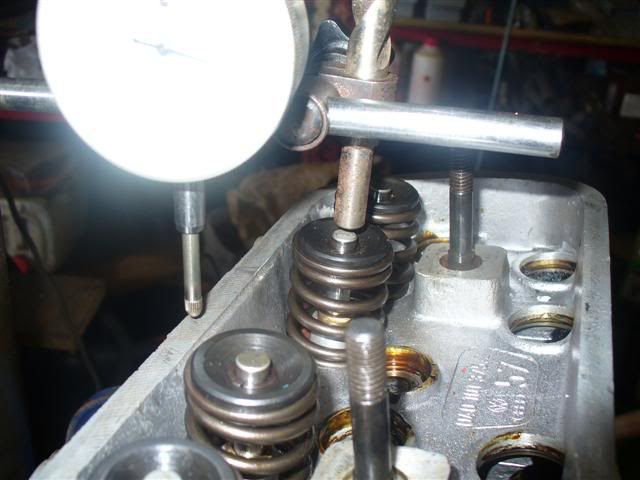

set geometry and easure actual lift at the valve with soft spring.

aim for 1.5mm clearance (any clearace will do to check with heavy spring),

measure lift with heavy spring,

then make sure you can push the valve down a further 1.5mm(or less if you dare!).

I used to use the milling machine digtal read-out to check my spring travels,

but Daimo's method with the dial indicator in a drill press works even better.

And get a rev limiter!

Ah, looks like te kettle has boiled.

| Quote: | Originally

posted by westi

That's mad Alan.

|

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on April 20th, 2009 at 03:34 PM |

|

|

my thread is a pain in the backside, so i'll try to summarize the POOP method here.......(again all these tools are sitting idle if you and Jak want

a weekend of fun).....the hardest part setting up the tooling properly so there is no slop causing varied measurements

STEP 1

retainer to guide clearence was checked and taken out of the way of the equation with bulk clearence (2mm after calculated lift + desired from bind

added on)

cut the guides down to 16mm clearence from retainer (my lift was 13mm)......

tool.....one end cuts valve guide other cuts guide boss for inner spring of dual sets

STEP 2

measuring lift at valve on dry built motor with actual cam, followers, rockers, dual springs, retainers, keepers, lash caps and good molly pushrods

(I FOUND CHANGING ANY OF THESE WOULD VARY MEASUREMENTS!)........

bracket on exhaust studs with magnetic dial indicator reading off retainer........i took measurements for each and every valve

STEP 3

taking bind measurements.....with the drill press loaded i would bottom the assembled spring to coil bind.......the dial indicator reads off the

tappet cover gasket surface and therefor takes out any movement that may occur of the press table/head stand etc (i later did this with both inner and

outer springs installed, these pics were a practice "photo shoot" run)

STEP 4

correct bind height with shimms to your desired "over lift" clearence.......

STEP 5.....repeat step 3 to check your new bind heights

HA HA now you know that i know poop about poop!

|

|

|

Jak Rizzo Jak Rizzo

Insano Dub Head

Posts: 837

Threads: 67

Registered: April 26th, 2004

Member Is Offline

Location: Central Coast

Theme: UltimaBB Pro Blue ( Default )

Mood: Pastizzi eating

|

| posted on April 20th, 2009 at 04:17 PM |

|

|

I have all those tools except for the cutting tool, although my father may have one (retired toolmaker)

Jak

I like poop

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on April 20th, 2009 at 04:25 PM |

|

|

| Quote: | Originally

posted by Jak Rizzo

I have all those tools except for the cutting tool, although my father may have one (retired toolmaker)

Jak

I like poop

|

i've quoted that one Rizzo so you can't get out of helping......put your polishing bits away....dust off the tools and get into it (you have to

still feel some sympathy for those of us silly enough to prefer one cam over four.....don't you ) )

|

|

|

Jak Rizzo Jak Rizzo

Insano Dub Head

Posts: 837

Threads: 67

Registered: April 26th, 2004

Member Is Offline

Location: Central Coast

Theme: UltimaBB Pro Blue ( Default )

Mood: Pastizzi eating

|

| posted on April 20th, 2009 at 05:39 PM |

|

|

Oh I help him alright,

Do u want a coffee CT?

U want a Patizzi too?

U want a 78mm crank with that?

u get the idea.

Then there is the comedy relief, fuck I'm funny. Ask CT, he'll tell u. Oh the hillarity!

Jak

|

|

|

matberry matberry

Super Moderator

Go hard or go home

Posts: 8114

Threads: 134

Registered: March 7th, 2006

Member Is Offline

Location: Cooroy Qld

Theme: UltimaBB Pro Blue

Mood: enjoying waving at all my Kombi buddies from my T3

|

| posted on December 24th, 2009 at 09:04 AM |

|

|

I know this is digging up some ancient history, but Bix offered an excel version.....any chance of getting that.

Also any other version of cam spec/comparisons out there?

If so I'd like to see please.

Thanks in advance.

Matt

| Quote: | Originally

posted by BiX

CT,

I have been running the W120 with 1.25:1 in my new engine. Done about 10k on it......... could be an option to reduce duration but not lift? try the

table below....do you want the excel version?

Cam Brand Spec Adver Dur Dur @ 0.05 Cam Lift 1.1 1.25 1.4

Tighe 356C 264 224 0.385 0.424 0.529 0.539

Tighe 149 270 230 0.360 0.396 0.495 0.504

Eagle (CB) 2233 270 234 0.371 0.408 0.510 0.519

Eagle (CB) 2239 276 234 0.380 0.418 0.523 0.532

Eagle (CB) 2234 274 234 0.387 0.426 0.532 0.542

Eagle (CB) 2238 274 236 0.319 0.351 0.439 0.447

Eagle (CB) 2236* 280 236 0.339 0.373 0.466 0.475

Eagle (CB) 2235 272 236 0.374 0.411 0.514 0.524

Tighe 548 280 238 0.375 0.413 0.516 0.525

Tighe 140A 288 240 0.330 0.363 0.454 0.462

Eagle (CB) 2241 286 240 0.386 0.425 0.531 0.540

Engle Fk7 288 244 0.357 0.393 0.446 0.500

Eagle (CB) 2237 278 244 0.421 0.463 0.579 0.589

Engle W110 284 247 0.392 0.431 0.490 0.549

Eagle (CB) 2242 298 248 0.389 0.428 0.535 0.545

Eagle (CB) 2240 286 248 0.430 0.473 0.591 0.602

Tighe 416C 290 251 0.368 0.405 0.506 0.515

Web-cam 86A 290 252 0.334 0.367 0.459 0.468

Engle W120 294 253 0.397 0.437 0.496 0.556

Tighe 148A 285 253 0.400 0.440 0.550 0.560

Web-cam 110 284 256 0.348 0.383 0.479 0.487

Tighe 253B 284 256 0.422 0.464 0.580 0.591

Engle VZ25 282 256 0.429 0.472 0.590 0.601

Engle Fk8 298 258 0.382 0.420 0.478 0.535

Web-cam 86B 300 260 0.383 0.421 0.527 0.536

Engle W125 301 262 0.418 0.460 0.523 0.585

Engle VZ30 298 262 0.461 0.507 0.634 0.645

Tighe 149A 298 263 0.393 0.432 0.540 0.550

Engle FK10 310 266 0.385 0.424 0.529 0.539

Engle W130 308 267 0.419 0.461 0.576 0.587

Engle FK46 301 268 0.409 0.450 0.562 0.573

Tighe 133 300 270 0.451 0.496 0.620 0.631

Engle W140 313 274 0.424 0.466 0.583 0.594

Engle FK47 308 276 0.419 0.461 0.576 0.587

Engle FK87 320 276 0.401 0.441 0.551 0.561

Engle VZ35 309 278 0.448 0.493 0.616 0.627

Tighe 1002 338 280 0.480 0.528 0.660 0.672

Engle FK89 328 282 0.416 0.458 0.572 0.582

|

Matt Berry Motorsports...air cooled advice, repairs and mods Ph 0408 704 662

OFF-ROAD,CIRCUIT,DRAG,STREET,ENDURANCE

|

|

|

Sides Sides

A.k.a.: Dave Sidery

Veteran Volks Folk

Posts: 2220

Threads: 59

Registered: May 20th, 2007

Member Is Offline

Location: Brisbane

Theme: UltimaBB Pro Blue

Mood: Need... more... shed... time...

|

| posted on December 24th, 2009 at 09:40 AM |

|

|

Cos I'm a nice guy Matt.... tho since that ain't true, maybe cos it's Christmas...

Anyway whatever the reason, here's an Excel version of BiX's table

(just a copy + paste with a formatting trick, so any errors above will also be in this Excel sheet)

| Error |

| Sorry, you must be a registered user in order to download attachments. |

|

VWDCQ vice pres & web dude - vwdcqinc.org.au

Join a car club - get car peeps

My toys

'70 Hillclimb Bug 'Jezebel' w/- Haltech EFI - http://bit.ly/VwTNtQ

'60 KG Coupe - resto kinda started

01 New Beetle - gf's car, but I turn the spanners |

|

|

matberry matberry

Super Moderator

Go hard or go home

Posts: 8114

Threads: 134

Registered: March 7th, 2006

Member Is Offline

Location: Cooroy Qld

Theme: UltimaBB Pro Blue

Mood: enjoying waving at all my Kombi buddies from my T3

|

| posted on December 24th, 2009 at 09:46 AM |

|

|

Thanks Dave.......mr Nice Guy

Merry Christmas.

Matt Berry Motorsports...air cooled advice, repairs and mods Ph 0408 704 662

OFF-ROAD,CIRCUIT,DRAG,STREET,ENDURANCE

|

|

|

BiX BiX

Veteran Volks Folk

Posts: 2499

Threads: 154

Registered: September 2nd, 2002

Member Is Offline

Location: Brisbane

Theme: UltimaBB Pro Blue ( Default )

|

| posted on December 24th, 2009 at 11:33 AM |

|

|

Are you implying my maths is wrong dave?

I have no sympathy for my car, only the wallet that pays for it!

Go hard or go home!!!!

|

|

|

Sides Sides

A.k.a.: Dave Sidery

Veteran Volks Folk

Posts: 2220

Threads: 59

Registered: May 20th, 2007

Member Is Offline

Location: Brisbane

Theme: UltimaBB Pro Blue

Mood: Need... more... shed... time...

|

| posted on December 24th, 2009 at 02:06 PM |

|

|

No worries Matt.

Nah BiX - not implyin anything mate !!!

VWDCQ vice pres & web dude - vwdcqinc.org.au

Join a car club - get car peeps

My toys

'70 Hillclimb Bug 'Jezebel' w/- Haltech EFI - http://bit.ly/VwTNtQ

'60 KG Coupe - resto kinda started

01 New Beetle - gf's car, but I turn the spanners |

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on December 24th, 2009 at 02:49 PM |

|

|

| Quote: | Originally

posted by matberry

Also any other version of cam spec/comparisons out there?

If so I'd like to see please.

Thanks in advance.

Matt

|

knock yourself out killa!......

http://www.actionimport.com/Tech_Files/cam_information.htm

|

|

|

PAZZAN PAZZAN

Wolfsburg Wizard

Posts: 592

Threads: 113

Registered: January 30th, 2008

Member Is Offline

Theme: UltimaBB Pro Blue

|

| posted on December 24th, 2009 at 04:09 PM |

|

|

looks like I finally need a new engine case ,how are the new alloy cases performing...

|

|

|

matberry matberry

Super Moderator

Go hard or go home

Posts: 8114

Threads: 134

Registered: March 7th, 2006

Member Is Offline

Location: Cooroy Qld

Theme: UltimaBB Pro Blue

Mood: enjoying waving at all my Kombi buddies from my T3

|

| posted on December 24th, 2009 at 11:23 PM |

|

|

Thanks for the link Daimo, know anywhere to get type IV spec's as well?

As for the Al cases, I'm not fully convinced yet!

Doing a rebuild on one soon, happy to share info upon inspection.

Matt Berry Motorsports...air cooled advice, repairs and mods Ph 0408 704 662

OFF-ROAD,CIRCUIT,DRAG,STREET,ENDURANCE

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on December 25th, 2009 at 07:07 AM |

|

|

yeah Paul.

know a couple of good engine builders that wont go with the ali cases...........but then Stan swears by them after he has machined them to his specs

and he only offered warranty on his high end motors after the ali cases came about.

for sure (as always) there are varying levels of quality with them..........Rudi had some new ones for sale a while back, so may be worth giving him a

buzz.

and yeah Matt, interested to see what you find on on inspection during the rebuild

|

|

|

bigrudi bigrudi

Wolfsburg Wizard

Posts: 401

Threads: 118

Registered: April 12th, 2005

Member Is Offline

Location: Sydney, Australia

Theme: UltimaBB Pro Blue ( Default )

|

| posted on December 25th, 2009 at 04:46 PM |

|

|

gees im convinced have run my alloy case for 6 seasons at over 120hp at the wheels and last year at 209bhp for 5rounds plus heaps of laps at the

natoinals see silver lbug going round and round and round . then ran the last four sprints of the year with 300 plus atw .checked out the case and

bearings as new put it back togeather same mains and bigends no fretting in case what so ever all machined surfaces are perfect std mag case engines i

have used show freting at joint surfaces and wear in bearing tunnels after only 2x rounds .A wise man told me a long time ago your case is the

foundation of your engine build weak link in type 1 engine is the mag case Ihave used both types and the alloy is the one may be slightly heavier 3 kg

but when preped properly will give excellent service cheers Rudi

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on December 25th, 2009 at 07:44 PM |

|

|

thanks Rudi, very informative!

|

|

|

matberry matberry

Super Moderator

Go hard or go home

Posts: 8114

Threads: 134

Registered: March 7th, 2006

Member Is Offline

Location: Cooroy Qld

Theme: UltimaBB Pro Blue

Mood: enjoying waving at all my Kombi buddies from my T3

|

| posted on December 25th, 2009 at 09:59 PM |

|

|

Thanks Rudi, I think you hit the nail on the head with the comment "when prepped properly". As with much of the gear from the Auto Linea foundry,

its the prep work that makes or breaks the build. Very nice to hear about your expierences with the lack of any sign of fretting even with all those

ponies in there.

Matt Berry Motorsports...air cooled advice, repairs and mods Ph 0408 704 662

OFF-ROAD,CIRCUIT,DRAG,STREET,ENDURANCE

|

|

|

PAZZAN PAZZAN

Wolfsburg Wizard

Posts: 592

Threads: 113

Registered: January 30th, 2008

Member Is Offline

Theme: UltimaBB Pro Blue

|

| posted on December 26th, 2009 at 10:23 AM |

|

|

Yeah the only problem with my motor is the case ,,everything else is still like new.. case cracked center main cradle on 1.2 cylinder side...really can't complain its been a tuff motor..now its time to decide to

rebuild or sell the parts & start a new project... case cracked center main cradle on 1.2 cylinder side...really can't complain its been a tuff motor..now its time to decide to

rebuild or sell the parts & start a new project...

|

|

|

bigrudi bigrudi

Wolfsburg Wizard

Posts: 401

Threads: 118

Registered: April 12th, 2005

Member Is Offline

Location: Sydney, Australia

Theme: UltimaBB Pro Blue ( Default )

|

| posted on December 26th, 2009 at 08:13 PM |

|

|

turbo sounds nice puts very big smile on dial have one case left ring me 0418442953 cheers Rudi

|

|

|

| Pages: 1 2 3 |