| [ Total Views: 303285 | Total Replies: 1178 | Thread Id: 80275 ] |

| Pages: 1 .. 33 34 35 36 37 .. 40 |

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 3rd, 2013 at 01:16 PM |

|

|

| Quote: | Originally

posted by bajachris88

Super hyper mega exciting stuff for Fraser! Just be sure to not run over Frog when you tower past on the sand

|

I have to get there first!

Still buttloads to do!!

Ordered a new set of gauges last night though. Had to spend the tax on something nice for the car

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

nils nils

Fahrvergnugen

Posts: 971

Threads: 65

Registered: January 11th, 2008

Member Is Offline

Location: central coast

Theme: UltimaBB Pro Blue ( Default )

|

| posted on September 3rd, 2013 at 07:54 PM |

|

|

I'm kind of excited to see the alyce MK2

Quit calling rust patina

|

|

|

matberry matberry

Super Moderator

Go hard or go home

Posts: 8114

Threads: 134

Registered: March 7th, 2006

Member Is Offline

Location: Cooroy Qld

Theme: UltimaBB Pro Blue

Mood: enjoying waving at all my Kombi buddies from my T3

|

| posted on September 3rd, 2013 at 10:12 PM |

|

|

| Quote: | Originally

posted by nils

I'm kind of excited to see the alyce MK2

|

x2

Matt Berry Motorsports...air cooled advice, repairs and mods Ph 0408 704 662

OFF-ROAD,CIRCUIT,DRAG,STREET,ENDURANCE

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 3rd, 2013 at 11:11 PM |

|

|

| Quote: | Originally

posted by matberry

| Quote: | Originally

posted by nils

I'm kind of excited to see the alyce MK2

|

x2

|

X3

Now if only someone would get off their butt and get some work done on her!

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 4th, 2013 at 12:13 AM |

|

|

Well. As most of you might know on the way to the Gold Coast VW show in May this year Alyce took a bit of a tumble. There were a number of

contributing factors but I think it has mostly been put down as a 'lack of talent' on the drivers part. Never mind. My passenger and I were both

fine, it was a very slow speed rollover. Unfortunately Alyce's body sustained some irreparable damage. We got her back on her wheels immediately and

she still ran like a dream. I was still able to attend the show and even managed to win a trophy, 'Dog of the Day'. Lets hope she can be back there

next year and get an award of a more positive nature!

In the few weeks leading up to the show I had put some time into a new engine cage mounted tyre rack. I'll put a few pictures of this up first and

then show you the damage.

This first picture is of one of my rear tyres with my spare sitting on top of it. The tyre rack had to be able to carry both. Which also had very

different offsets on the rims. I also had to mount it so that it didn't cover up my number plate or obscure the view out the back window too much.

First thing was to fit the larger tyre and make the mount high enough that it cleared my plate. I didn't really care if the back window was covered

because if it was on there I would only be limping home at slow speed etc.

I added a bunch of mounting tabs to the cage and started getting the frame roughed out.

One problem I've had in the past is threads I have drilled and tapped into the engine cage to hold the cover down have stripped out and I've had to

go to a larger size. I added the 12mm plates so there was plenty of meat for a secure mount. You don't want them stripping out and your spare

cartwheeling off the back of the car into traffic.

Here is the spare sitting in place. This is as low as I can mount it without covering my number plate up. View out the back is still pretty good.

You might have noticed that the exhaust actually sits slightly proud of the mounting face. And the spare sits over the top of it. Clearance was tight

and took lots of measuring and working out. All of the wheels and tyres clear it fine. I have been checking with one of my fronts too.

And now for the mounting plate. I had an old spare hat style disc left over from when I did my rear brake conversion. So I chopped it up and used it

for the mounting plate. I got some M12 threaded rod for the wheel nut to mount on and holds the wheels on the back.

And here it is all done. This was the night before I drove down (about 800km) to the show. It's not super pretty, but the idea was to sort it out and

make any changes when I got back. I am happy to say that it performed perfectly and is even rollover proof.

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 4th, 2013 at 12:26 AM |

|

|

Here's a few pictures of the carnage. She rolled over to the left 3/4 of a turn and ended up on the RHS. Didn't take much to get here upright again

but I was not very pleased with myself. Doesn't look too bad in these pictures, after the show we spent the afternoon kicking the roof back out so it

was semi round again, and disassembled the LHS door and straightened it out enough so the glass could go up and down again.

And here is the new body that she will be receiving. It's a later model being a 1969 1500. I had always planned at some stage to swap to this body

for all of the upgrades they offer. Things have just gotten a little bit moved ahead in schedule now

You will also notice that this body has already been chopped into a Baja. I managed to pick it up for a good deal off a friend about a year prior.

Cause it's already cut I can't be blamed for "ruining" another nice beetle by the purists. Like a really care what anyone thinks anyway!!

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

nils nils

Fahrvergnugen

Posts: 971

Threads: 65

Registered: January 11th, 2008

Member Is Offline

Location: central coast

Theme: UltimaBB Pro Blue ( Default )

|

| posted on September 4th, 2013 at 05:38 AM |

|

|

Always thought that was the best place for spare tyre, usually just found i onlycarried a spare frnt. but that said never ever had a single flat on

the baja.

Any thoughts on the colour for the new body? Or are you going to just anchor wax it and run like the cool kids?

Quit calling rust patina

|

|

|

Allbones Allbones

Officially Full-On Dubber

Posts: 395

Threads: 58

Registered: July 5th, 2012

Member Is Offline

Location: Ipswich QLD

Theme: UltimaBB Pro Black

|

| posted on September 4th, 2013 at 08:43 AM |

|

|

Sucks about the roll over dude. Bad luck, at least have some fun with it while you dont need to care about the body

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 4th, 2013 at 09:41 AM |

|

|

| Quote: | Originally

posted by Allbones

Sucks about the roll over dude. Bad luck, at least have some fun with it while you dont need to care about the body

|

This is what I should have done. But silly me I stripped it down.

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 4th, 2013 at 09:55 AM |

|

|

It wasn't long before I had the first body off and strip down had begun. I had it sitting on some milk crates and car stands. But decided to buy some

box and castor wheels and make a body trolley. So far it has been amazingly useful. I think once the car is done I'll put a top on it and turn it

into a welding bench.

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 4th, 2013 at 10:05 AM |

|

|

Then it was time to pull her old body apart for the last time

This one took a bit longer as it had a bit more fitted to it than the other shell. And there was a lot more mud and sand holding some of the pieces in

place!!!

I'm going to have to do a far better (read neater!) job of the wiring this time! Though, surprisingly I never had a single problem with it!

I also cut the fuel filler out so I can fit it to the new body.

The floorpan will need some tidying up. Ground clearance certainly gets impressive without a body weighing it down!

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 4th, 2013 at 10:18 AM |

|

|

Now it was time to start sorting the new body out. I bought a 7" grinder/buffer and started taking some paint off. When I stripped the inside of the

door of winder mech/handles I noticed some blobs in the bottom of the door crevice. Yep! she had bog. A few nice blobs too!

And the gap under the back window had completely rusted out.

I opted to get the body blasted. I really wanted to do this body once and do it all properly from the start. So I won't have it rusting or breaking

out it cracks in a few years time.

So on the trailer she goes.

All blasted now, and ready to come home. But look what we've uncovered!

As soon as I got her home I put her into the booth and got a few coats of 2pac epoxy primer onto everything to stop it rusting. Now I just have a lot

of body work ahead of me. What we thought was a straight and rust free body has turned out to be a straight (thankfully) but quite holy body!

Wish me luck.

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 4th, 2013 at 10:28 AM |

|

|

So I went and bought a new drill/driver set. And got myself a spotweld drill. And started removing sections of the firewall so I can repair the gaping

hole under the back window.

And I managed to roll the car again, even slower this time

I really need to get both of the heater channels replaced with new items. So I started building the bodylift for the car. I'm using 100mm C-channel

for the lift which will give me 80mm of lift (just over 3" for the imperial minded). What I'm going to do is make the lift kit and use it as a jig

to replace the sills one at a time.

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 4th, 2013 at 10:38 AM |

|

|

Floorpan time!! I dragged it back into the shed and lifted it up onto my trolley so I could strip it too. I'm planning to replace the framehead too.

When I built the car I used a Super floorpan and added a K&L front to it. I bought a brand new one. And what a mistake that was! The metal was

thin, welds were poor, fit was horrible and lots of gaps everywhere! And 3 years on it's rusting everywhere and completely bent out of shape. I'm

going to cut it off and replace it with a good second hand one off a spare pan I have here at home.

Other plans is to replace the brake and fuel lines. Run a line for the hydro clutch, and set the pedals up for it. Converting to rack and pinion

steering. Widening the front end with new shock towers. And obviously, welding on my lift kit.

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

grinderman grinderman

Officially Full-On Dubber

Posts: 378

Threads: 50

Registered: April 27th, 2011

Member Is Offline

Location: Grantham

Theme: UltimaBB Pro Blue ( Default )

|

| posted on September 4th, 2013 at 07:09 PM |

|

|

Holy crap! My favourite build thread has taken a twist I was not expecting. I guess starting again will let you change the things you weren't happy

with on alyce no.1. Good luck. But we all know Smiley will have it finished by warwick.....................

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 4th, 2013 at 11:02 PM |

|

|

Ok. Where were we?

Frontend. Here's a little something I knocked up so I could coax a little more travel out of the front end. Cut out of 6mm plate. They are about 5"

taller than standard ones. I will be running Bay Kombi rear shocks as they are nice and long and fit very well.

Then I set about widening the front a little. 2" to be exact. I had an old beam lying around so I cut the centre grub screw out and welded it into

the new beam I was making. I also did a cut and turn while I was at it. I've had adjusters in the past and while they are nice I never really

bothered adjusting them. Screw them up as high as they went and they were like that for years. Plus they let sand and dirt into the beam. So standard

screws it is!

I use angle and stainless hose clamps to ensure that the beam stays straight. I've used this method a few times and it works great. Make sure you

measure measure measure and make certain that everything is in the right spot. What I like to do is tack the beam in 4 places around the

circumference. Grind these down smooth so it all sits flush in the angle. Weld out as much as you can on both tubes. Then remove one piece of angle

and swap it onto the other side of the beam. Use some small blocks of metal on the flat sections to space the angle up above the welds you have just

done. Then finish welding the back side of that tube, then do the same on the last tube. Easy peasy, and the beam stayed perfectly straight!

Now because it's widened the beam clamps are now in the wrong spot. So it's time to cut them off and move them too. I left them and the shock tower

on during the widening to help keep everything straight and square. I sprayed them a good coating of weld thru primer before fitting them back to the

beam. And I figured the best thing to use as a jig was the framehead itself. So I bolted them on, measured and made sure it was centred. Tacked in

place then removed and welded out.

Then I cut the old standard shock towers off and tacked my new ones in place. I took plenty on measurements so I could get them sitting in the right

position on the beam. Then I threw an arm in the beam and an old shock on to see how it would go. I know I won't get this much travel once the stops

are in place but it's quite impressive!

I have showed you this picture already.

And that is how you build a manly beam for your Baja with mostly stock bits and a bit of plate.

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

nils nils

Fahrvergnugen

Posts: 971

Threads: 65

Registered: January 11th, 2008

Member Is Offline

Location: central coast

Theme: UltimaBB Pro Blue ( Default )

|

| posted on September 5th, 2013 at 06:11 AM |

|

|

Love that when you start welding big steel items and can sit back, admire your work and think. . .

. . . . .

MMWWWWAAHAHHAHAHHAHA !

With the wider front end, I assume you will add beamclamps to the chassis. concider adding more caster to your set up before you fab those. otherwise

the bottom clamps don't reach and you end up feeling pretty silly

Quit calling rust patina

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 5th, 2013 at 10:39 AM |

|

|

Just a quick one. A little bit of messing around that I got done last night.

As I mentioned I'm converting to Rack and Pinion with my new front end.

The rack I'm using is out of a Mk I Golf. The cool thing is because I've widened the beam that small amount the rack ends are the exact prefect

length.

One other thing to note for those playing at home. The rack ends that I have are Golf ones, and they are the same taper/size as Balljoint Beetle (or

Country Buggy in my case). But if you get Mk I Passat rack ends, they are the same taper/size as a K&L pin Beetle. So you can use this rack on

either beam, just get the right rack ends for your application.

Now I know you want to see pictures!

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

OZ Towdster OZ Towdster

A.k.a.: Andrew Westwood

Custom Title Time!

Keen to finish some projects

Posts: 1921

Threads: 132

Registered: December 7th, 2003

Member Is Offline

Location: Alexandra Hills Brisbane QLD

Theme: UltimaBB Pro Yellow

Mood: Having fun in our great land

|

| posted on September 5th, 2013 at 05:51 PM |

|

|

If your going to replace that frame head i would cut the old one off 40mm foward or cut your replacement german one off 40mm rearwards (preferable

option )with the main aim of moving your beam foward 40mm which will help with your turn in and big tyres not srapping on inner guards anywhere , plus

you know your going to end up with longer front trailing arms sooner or later and they'll put your whels back in the stock position .

But if you are thinking about bigger front arms now would be the time or you'll be remounting the rack when you do to get rid of bump steer .

Don't let body work get in the way of real suspension travel

|

|

|

nils nils

Fahrvergnugen

Posts: 971

Threads: 65

Registered: January 11th, 2008

Member Is Offline

Location: central coast

Theme: UltimaBB Pro Blue ( Default )

|

| posted on September 5th, 2013 at 07:58 PM |

|

|

Like andrew said,

Also, its hard to tell because i don't have a computer handy. Is the golf rack end load? Because the theoretical position of the inner ball joints is

the same no matter how long your steering arms, the shorter they are, the less tolerant the misalinement of the rack will become. as an example a the

difference between drivable and a nightmare is only 5mm on a centerload, maybe half that on end load? And of coarse shorter arms means less travel and

nobody wants that!

Have you had a chance to see how the drivability of your rack turned out Andrew?

Quit calling rust patina

|

|

|

AndrewB AndrewB

Seriously Crusin Dubber

Posts: 141

Threads: 19

Registered: June 18th, 2011

Member Is Offline

Location: Sydney

Theme: UltimaBB Pro Blue ( Default )

Mood: arghhbjfhbejrhfebf

|

| posted on September 5th, 2013 at 11:22 PM |

|

|

This thread just keeps getting better and better.......

Shame about the roll over, I felt your pain when i saw that roof damage, brought back memories of what mine looked like before i spent hours and hours

straightening it....

Keep up the awesome work.

And im so happy you are finally doing a body lift

Are you going to be boxing those shock towers? gusseting? that beam is awesome.

PS: those spot weld drills suck balls, I have broken like 7 of the stupid things, they dont last very long at all.

I was much happier with the solid spot weld drill bits with the spike, obviously the bits have two different applications, but if you can weld it

doesnt really matter.

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 6th, 2013 at 02:56 PM |

|

|

Ok smarty pants (Nils and Westwood) wouldn't I be better off moving the framehead forward the same amount as the arms? Aren't they only available in

2 1/2" or 4" longer? So I should move it forward about 60mm at the very minimum?

Thanks for the comments AndrewB. I will be gusseting the towers, they are just tacked in place for the moment so I can cycle the suspension and do all

the bumpsteer business.

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 6th, 2013 at 03:02 PM |

|

|

And Nils, the Golf rack is end load. I'm aware that makes the fine tuning a little more sensitive. I've read through Wes's thread about 5 times in

the last few years.

Just wondering how you went with the calculator? Did you just measure everything on your car and transfer the numbers in and it told you where the

rack would be? Then you trail and error a little from there to get it perfect?

Because the calc is made for balljoint. Did you put the upper and lower spindle balljoints as where the line of the king pin intersects the line of

the Link pin? I figure that's the same as it's where it technically pivots on two points.

Andrew. When you did yours and cycles the suspension. How the hell did you hold the trailing arms in the correct spot with no torsion leaves fitted?

I'm having troubles with them sliding in and out on the bearings a little. I picked up some threaded rod to maybe try and lock them at a set length

where the torsion leaves would normally hold them.

I know doubt will have a millions more questions so please keep checking back and keep an eye on me

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

matberry matberry

Super Moderator

Go hard or go home

Posts: 8114

Threads: 134

Registered: March 7th, 2006

Member Is Offline

Location: Cooroy Qld

Theme: UltimaBB Pro Blue

Mood: enjoying waving at all my Kombi buddies from my T3

|

| posted on September 6th, 2013 at 03:28 PM |

|

|

I've used threaded rod for mock up, when the seal are installed you can gauge the crush on the seal to get it similar to how the arms sit when the

torsions are installed.

I reckom ,ove the frame head too... how much depends on what arms, but a little more tyre clearance is a good idea IMO.

Matt Berry Motorsports...air cooled advice, repairs and mods Ph 0408 704 662

OFF-ROAD,CIRCUIT,DRAG,STREET,ENDURANCE

|

|

|

nils nils

Fahrvergnugen

Posts: 971

Threads: 65

Registered: January 11th, 2008

Member Is Offline

Location: central coast

Theme: UltimaBB Pro Blue ( Default )

|

| posted on September 6th, 2013 at 07:07 PM |

|

|

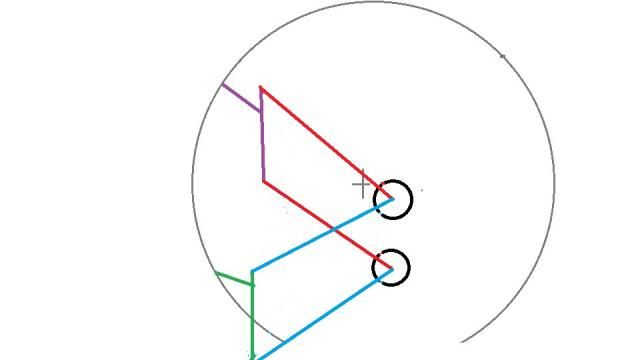

Righto smiley you have got me to go to the computer. Lets start with Wes' calculator, I didn't use it per say but it did help me understand how the

movement in the front end effect bump steer and how to find the ''sweet spot'' From there I moved back to where I was more comfortable, (with

something tangible in my hands, not computer code) Computers and I don't really work well together. Drafting on the other hand, I'm old hat at.

I've drawn a Quick representation of what I drew in full size. First you will have to measure where all the moving point are on your spindles and

steering ball joints (remember that the movement point on a ball joint you cant actually see, it's the centre of the ball) Measuring the outer ball

joint in relation to the link pins in only 2 dimensions is a pain, but keep at it it's a very important dimension. If I can find my old drawings I

will post my measurements seeing as you have the same spindles.

Now, on your great big piece of drafting paper draw this perfect side on view of your torsion bars, arms, spindle at full expected droop. And again

at full compression (using the same torsion bar you drew the first time). Continue drawing this though out the range of travel as many times as you

need to build the ark that your out steering ball joint travels though.

Then all you have to do is find the center point of that ark, and [size=6]BAM![/size] this is the sweet, sweet caramel and nougat center of your

inner ball joint

This is why I couldn't tell you (westwood) for absolute sure that you could use the same dimensions as my build when you where setting up your

rack.

But in smileys case, this is where your end load rack will come into its own. The centerload racks always require reshaping of the top of the frame

head to get it in the right spot. I believe you get away with out (or very minor) because you have no moving parts there to account for

Onto the subject of the stretched frame head. aside from clearancing for longer arms the best reasons for stretching is to lengthen the wheelbase for

smoother ride, better stability and to try and rescue the dynamics of the car, seeing as we have butchered it so. The ''right'' amount to stretch

it would be the same percentage that you have widened it. Widen it 5%, stretch it 5%, easy yeah? Otherwise you end up with the same (and i'm going to

get grilled here) situation as the short manx buggies. Your ackerman all kinds if messed up.

Hope I have made a few things that seem difficult alittle more user friendly

Quit calling rust patina

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 6th, 2013 at 07:08 PM |

|

|

Thought I post post a few more pictures of some goodies that I have picked up.

First off 5-speed trans out of a T3 Kombi/Vanagon. These have a heap of improvements over a bay Kombi trans. Including a proper reverse gear (nice and

strong), 4 spider diff, lower first gear (great for crawling), hydraulic clutch, deeper bellhousing so I can fit the 228mm flywheel and clutch etc

etc.

I also picked up a Weddle linkage kit for it. Which should make fitting it and adapting to the bug stuff a little easier.

To compliment this lovely gearbox I got my hot little hands on a difflock! Same as the ones used in the Syncro buses. Thanks a million to Paul form

Steelart for organising this. So now I really will be a 2WD!

Plan is to have it air activated.

I really can't wait to get all this up and running!

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

nils nils

Fahrvergnugen

Posts: 971

Threads: 65

Registered: January 11th, 2008

Member Is Offline

Location: central coast

Theme: UltimaBB Pro Blue ( Default )

|

| posted on September 6th, 2013 at 07:12 PM |

|

|

OH! almost forgot.

Yep threaded rod, throw your torsions away and get some coils while you are at it

Lock your wheels in place on the ground (with toe set) and raise and lower the chassis to simulate the travel

That gearbox is SSSWWWWEEEEEEET!!!!

Quit calling rust patina

|

|

|

grinderman grinderman

Officially Full-On Dubber

Posts: 378

Threads: 50

Registered: April 27th, 2011

Member Is Offline

Location: Grantham

Theme: UltimaBB Pro Blue ( Default )

|

| posted on September 6th, 2013 at 07:20 PM |

|

|

Wow.........you got the shit now! It's a win/win with that box set up, crawler gear for tough stuff and a 5th for the highway, and with the locker

you can piss that dual handbrake setup off

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 7th, 2013 at 10:16 AM |

|

|

Nils! You are a genius. That is the simplest explanation I've heard and very easy to comprehend. I'm thinking that I need to get some more accurate

measurements off the spindle. Measuring the ball joint isn't as hard cause I made one of these out of an old balljoint. Makes it a little easier.

I think that I'll have to go and get some large drawing paper now too.

I put all the measurements that I got into the calculator and came up with 35.6mm up and 135mm back for the rack position, giving 0.9mm bumpsteer at

the end of my tyres. And even rounding the first measurement out to the nearest mm in either direction took it up to 1.3mm. That's crazy sensitive! I

can understand now why people carry on like setting racks up PROPERLY is voodoo science!

Thanks for all your help.

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

Smiley Smiley

A.k.a.: Daniel Stephens

Veteran Volks Folk

Posts: 2125

Threads: 110

Registered: October 29th, 2008

Member Is Offline

Location: Yeppoon, Central Queensland

Theme: UltimaBB Pro Blue

Mood: Synchro'd

|

| posted on September 7th, 2013 at 01:06 PM |

|

|

Well I took Nils advice and went and bought some paper and broke out the old compass, rulers and protractor. It's been ages since I've done any

drawings like this and I can say I quite enjoyed it

I plotted the suspension at 5 different points. From literally sitting the shock against the tower in both directions. (Will end up with less than

this once stops are in place I would say). Lower arm travels a 125° sweep. Then used these points to plot the centre of the circle and where my rack

should sit. The "sweet spot" is 23mm up and 61mm back from the centre of the top torsion tube. Way cool! Now I just need to build it and see how

much more fine tuning is required from here.

Smiley

If you said I was a Volkswagen man, you'd be right.

|

|

|

| Pages: 1 .. 33 34 35 36 37 .. 40 |