| [ Total Views: 222529 | Total Replies: 708 | Thread Id: 38560 ] |

| Pages: 1 .. 4 5 6 7 8 .. 24 |

|

|

dangerous dangerous

A.k.a.: Dave Butler Muffin Man

23 Windows of Awesome

Posts: 5901

Threads: 178

Registered: January 6th, 2005

Member Is Offline

Location: Gold Coast

Theme: UltimaBB Pro Blue ( Default )

Mood: 591

|

| posted on February 27th, 2007 at 06:07 AM |

|

|

| Quote: | Originally

posted by dumone

there are MARS bars riding on a completion date now:kiss

| Quote: |

Sounds like Jeff.

He bet me one back in the 90's he would run a 9 before me.

At the time he was sponsoring Rodney, so I never collected...

|

|

| Quote: | Originally

posted by westi

That's mad Alan.

|

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on March 20th, 2007 at 07:48 PM |

|

|

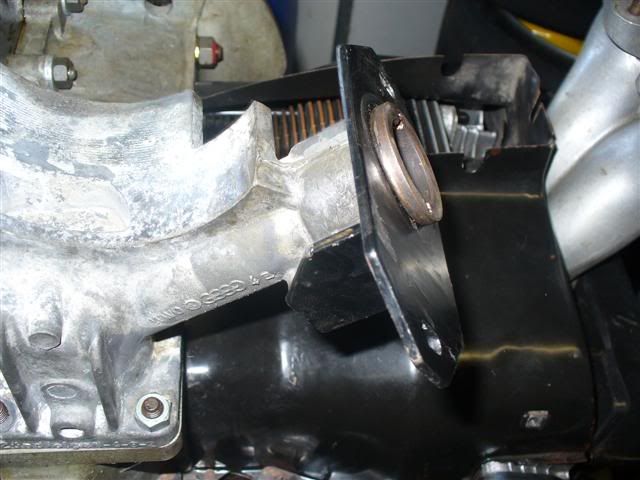

still waiting for some 1.45 rockers to arrive to be able to finish the spring set up so i've had push on with other bits and pieces.......

flanging the exhaust........

the flanges i had needed opening up to be able to fit the 1 5/8........a holding jig was knocked up and it was back to the lathe to open four flanges

up to tightly fit the flared side of the headers joins, and four more to match the tubes O.D to make it all possible......

some CV joint bolts were turned down on the head in order to clear the exhaust tubes.....

i'm after both the benefits of additional strength here........

and improved sealing here...........all ready to be tacked, removed and fully welded

[ Edited on 2-4-07 by dumone ]

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on April 2nd, 2007 at 07:53 PM |

|

|

ooorkay, welded up, time for clean up!

being a very tight fit on the slip joints to start with, the slightest blemish created by the mig (in the pipes) was going to need tidying up before

the exhaust would even go back together!......more die grinding! the collector was going to need the most porting/streamlining, the collector was going to need the most porting/streamlining,

but as usual, I can't help but do the works..........

........"at the head" flanges......

fiddle de deeeeeeeeee

all the joints and primary's are now clean as a whistle, anything for a couple of horsepower

must get back to that collector that i was supposed to be doing, so i can install the bung for the air/fuel sensor.......maybe tomorrow

|

|

|

tassupervee tassupervee

A.k.a.: Knob Jockey

Custom Title Time!

That really hurts doesnt it!

Posts: 1171

Threads: 25

Registered: September 21st, 2003

Member Is Offline

Location: Huon Valley SouthernTasmania

Theme: UltimaBB Psyche Blue

Mood: Moody!

|

| posted on April 2nd, 2007 at 08:38 PM |

|

|

Hey Dumone

Thats a nice merge.

Could you take a pix of up its bum?

Id like to have a look at the merge on the inside from the outlet end.

Secondly, did you take into account the order the zorst pulses enter the merge?

Just interested.

L8tr

E

Im not a complete idiot, quite a few parts are missing....

|

|

|

LIFE IN THE LOW LANE LIFE IN THE LOW LANE

A.k.a.: Brennden Alder

Son of Jim - Creator of Good

All people have the right to stupidity but some abuse the privilege

Posts: 2534

Threads: 53

Registered: March 11th, 2007

Member Is Offline

Location: Murrumba Downs - Brisbane

Theme: UltimaBB Pro Orange

Mood: What Kombi wants vs what Kombi gets are nowhere near the same...

|

| posted on April 3rd, 2007 at 09:38 PM |

|

|

| Quote: | Originally

posted by tassupervee

Hey Dumone

Thats a nice merge.

Could you take a pix of up its bum?

Id like to have a look at the merge on the inside from the outlet end.

Secondly, did you take into account the order the zorst pulses enter the merge?

Just interested.

L8tr

E

|

The absolute "must do's for HP gains of a Formula Vee". Definate HP gains on any motor....

You obviously have set the primaries to a certain length to match cam/engine specs for best power too. Nice looking work there!!

[size=4] ACCEPT THAT SOME DAYS YOU ARE THE PIDGEON AND SOME DAYS YOU ARE THE STATUE[/size]

Alder Outlaws VW Racing - check it out on fb!!

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on May 1st, 2007 at 07:04 PM |

|

|

ooooorkay then, the Zorst's bum:P

this is how it looked with a rough clean up......

.....i decided to weld it up and port it out again, if you reckon it still looks rough, well, after welding i was almost in tears-FUGLY!......

getting there.....

time for the air/fuel sensor........

DOH!!!!!!!, that just created more work.......just look at those flow suffocating bumps!

anything is something after yet another break.......still waiting for those 1.45's..........6 weeks airmail from U.S

i think i've been ripped off for the first time

|

|

|

Dasdubber Dasdubber

A.k.a.: Alan Agyik

23 Windows of Awesome

DAS Resto Haus

Posts: 5746

Threads: 289

Registered: August 26th, 2002

Member Is Offline

Location: Gold Coast

Theme: UltimaBB Pro Blue

Mood: feeling fine...

|

| posted on May 1st, 2007 at 07:27 PM |

|

|

I love you work Daimo....but you gotta give me some details of that splitty up in the air! Is that Luke's maybe?.

I am looking forward to getting stuck into my turbo manifolds (exhaust and inlet) with the mig once the type IV goes in the oval....I got a new

welding helmet for my birthday and haven't used it yet!

Keep up the good work mate!

Alan

[ Edited on 1-5-2007 by Dasdubber ]

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on May 21st, 2007 at 07:23 PM |

|

|

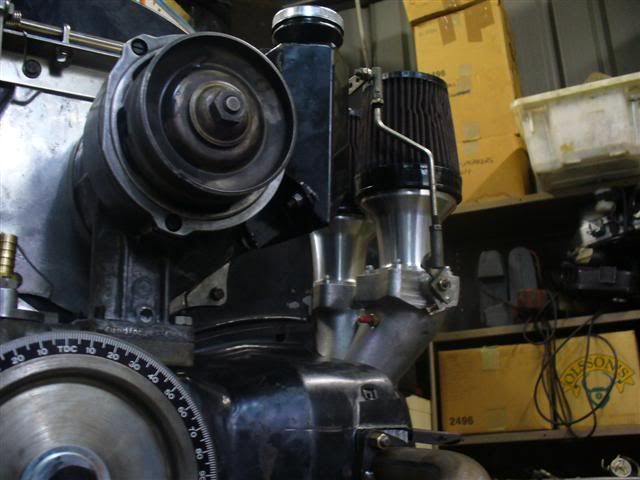

.......oh that old bit of this, bit of that, ginormous engine bay'd thing......it's just background filler!.........

Tinwear fiddling.........

on other fronts, i have dug up my old engines tinware set and grabbed some watercooled kombi valve covers and bails ready for modifying.........why

the h2o covers.....

.... well the theory that they would have been removed far less often due to the hydrualic lifters negating the need to do regular valve

adjustments......... definately rang true after cleaning them up...... the gasket surface was perfectly scratch and dent free....

myth confimed

.....it takes a bit of cutting to be able to get those manifolds home..................holes/tubes on both sides of the rear tinware piece, will be

vented via tubing down to the area of high air pressure/flow beneath the rear torsion bar housings..........this will help ensure there is enough air

available in the engine bay for BOTH the carbs and fan with a closed decklid

exhaust and manifolds fitted up A.O.K........

........i had to check the angles of "'ol favourites" tappet cover drains. They look spot on to go round the exhaust and will soon be copied to

provide the 3/4 inch drains directly back to the sump

.......they are also vented with a brass oil fitting at the front top corner (1/2 inch), to run back to the breather box, which was raided from the

engine currently pushing my daily,along with some other good bits, last weekend.

the single port copper intake gaskets are good for sealing at the oil filler:thumb.........

of course the berg breather bolted up perfectly:P

the breather is baffled inside to separate the oil out of the air, returning via the filler as usual. the top vent is connected to the aircleaners to

provide case vacumn as per standard, each of the lower ones are connected to the tappet covers and fuel pump block off respectively.

german tinwear GOOD, aftermarket BAD!.......

the repro "cool tins" under the cylinders sounded like a good idea......until i tried to fit up the rest!......they interfere with the standard

bits.........i had to flatten out the dimples that normally scoop around the cylinder.

yeah it looks rusty and rough, as usual, this is just mocking up so mods can be done before paint...

same story with the rear tin that runs down to protect the push rod tubes...........yes you can actually use these with a berg

exhaust:thumb........ever had a look at a "case" that has been run for a decent length of time without these tins??..............i have and they

provide the last peice of the "jig" that holds ALL the other tinwear sturdy enough to not scrub back and fourth aginst the soft magnesium adjacent

to the cylinder spiggots........i will also use silicon to stop the gouging:thumb

rear of the dog........again, crappy fitment is assured with aftermarket junk. i might even swap out to a late original shroud yet......

DOH!!!!!! i never realized just how close i was getting.......

..........just need some paint and polish really .....sure .....sure

hang in there baby, not long........

fingers crossed for sure, one center stud sheered off, four loose (like almost dropping off!!) and one at 10ftpd, maybe we all need to cross

fingers........(yes i have "addressed" those 6 center mains problems...well sort of)...........

ooo oo, just got a big box from the courier, have a look tomorrow for some real induction clobber that will make tose 48's look very old hat

indeed!!!!!!!!!

[ Edited on 21-5-07 by dumone ]

|

|

|

dangerous dangerous

A.k.a.: Dave Butler Muffin Man

23 Windows of Awesome

Posts: 5901

Threads: 178

Registered: January 6th, 2005

Member Is Offline

Location: Gold Coast

Theme: UltimaBB Pro Blue ( Default )

Mood: 591

|

| posted on May 22nd, 2007 at 06:48 AM |

|

|

Did your rockers turn up Daimo?

| Quote: | Originally

posted by westi

That's mad Alan.

|

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on May 22nd, 2007 at 06:21 PM |

|

|

yes Dave, they did.......back in Pasadena U.S.A!!!!!!!!!!!!!

they got returned to sender for some reason:puke......trying again none the less.

mind you, the mail man did come through with some goodies for me.........

it wasn't my carb linkage tho..........

...i found it hard to have "words" with Mr Mailman about the rockers when he presented me with these babies....

complete with injectors, rails and T.P.S

...even came with 4 aircleaners

all that needs doing is to open the cylinder tin a bit more and they're butter linkage looks good to go with the T.B's................computer, wiring harness, decent fuel lines and pump needed linkage looks good to go with the T.B's................computer, wiring harness, decent fuel lines and pump needed

|

|

|

56astro 56astro

Custom Title Time!

Posts: 1772

Threads: 74

Registered: August 25th, 2002

Member Is Offline

Location: The Nambucca

Theme: UltimaBB Pro Blue ( Default )

Mood: Pobjoy Powered with twin ignition & soon to be EFI'd

|

| posted on May 22nd, 2007 at 06:35 PM |

|

|

Unreal man

VW car, VW engine ...... keepin it "real"

35MPG on 101.3kPa |

|

|

Craig Torrens Craig Torrens

A.k.a.: Craig Torrens

Scirocco Rare

6 times Australian, 7 times State Hillclimb Class Champion

Posts: 8040

Threads: 347

Registered: January 10th, 2003

Member Is Offline

Location: Sydney

Theme: UltimaBB Pro Blue ( Default )

Mood: Time to go Salt lake racing, and actually achieve a result.

|

| posted on May 22nd, 2007 at 09:18 PM |

|

|

That is one fine 1776cc  ............I think you need to put a

stroker crank in!.........................Surely Jeff has one floating around ???:duh ............I think you need to put a

stroker crank in!.........................Surely Jeff has one floating around ???:duh

|

|

|

dangerous dangerous

A.k.a.: Dave Butler Muffin Man

23 Windows of Awesome

Posts: 5901

Threads: 178

Registered: January 6th, 2005

Member Is Offline

Location: Gold Coast

Theme: UltimaBB Pro Blue ( Default )

Mood: 591

|

| posted on May 23rd, 2007 at 05:50 AM |

|

|

Very nice Daimo, you must be rich dude!

| Quote: | Originally

posted by westi

That's mad Alan.

|

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on May 23rd, 2007 at 06:53 AM |

|

|

nah Dave, big credit card.........those T.B's were cheaper than a set of Kadrons anyways

|

|

|

dangerous dangerous

A.k.a.: Dave Butler Muffin Man

23 Windows of Awesome

Posts: 5901

Threads: 178

Registered: January 6th, 2005

Member Is Offline

Location: Gold Coast

Theme: UltimaBB Pro Blue ( Default )

Mood: 591

|

| posted on May 23rd, 2007 at 07:34 AM |

|

|

Cool score!

| Quote: | Originally

posted by westi

That's mad Alan.

|

|

|

|

pete wood pete wood

A.k.a.: figure itout

23 Windows of Awesome

Posts: 6828

Threads: 389

Registered: January 15th, 2004

Member Is Offline

Location: Nth Nth StMarys, Sydney

Theme: UltimaBB Pro White

Mood: upgrades = jackstands

|

| posted on May 24th, 2007 at 11:17 AM |

|

|

I'm not usually jealous of VW motors, but that is TOTALLY HORN!!!

hurry up and finish it so we can see the dyno readout.

[ Edited on 24-5-07 by pete wood ]

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on May 29th, 2007 at 06:56 PM |

|

|

yes yes Craig, tell me 'bout it!!!.....i've got my eye on a certain 78mm...........and there's another engine there with a custom 77.5mm to come in

under 2 liters (with 90.5) so i can come and play with you guys

apart from that,not much to say today...tins are good to go after doing another set of cylinder covers....... just got to get off my hiney and paint

it all now

was wondering where those dellorto stacks were..

these beasts make me laugh my butt off every time

|

|

|

bond bond

Veteran Volks Folk

Posts: 2456

Threads: 166

Registered: July 11th, 2003

Member Is Offline

Location: brisbane

Theme: UltimaBB Pro Blue ( Default )

|

| posted on May 29th, 2007 at 08:46 PM |

|

|

hot. oh so very hot.

nick

|

|

|

dangerous dangerous

A.k.a.: Dave Butler Muffin Man

23 Windows of Awesome

Posts: 5901

Threads: 178

Registered: January 6th, 2005

Member Is Offline

Location: Gold Coast

Theme: UltimaBB Pro Blue ( Default )

Mood: 591

|

| posted on May 30th, 2007 at 05:20 PM |

|

|

Oh? Oooohhhh.

Pass the Kleenex!

| Quote: | Originally

posted by westi

That's mad Alan.

|

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on June 5th, 2007 at 06:45 PM |

|

|

good things come in three's..........

A: i finally recieved my 1.45 rockers

B: "found" a haltech ECU

C: more importantly, got one more job done that i had been putting off

Valve cover drains

pucker up and drill some big holes in your sump. doing this feels soooo wrong .......tap the suckers out. .......tap the suckers out.

the holes were located as high in the walls of the sump as possible......

3/4 inch fiitings protrude well into the sump to help prevent the oil running upwards during cornering and needed to be offset different on each side

to allow for alignment to the heads

some pipe was bent up, ready for brazing (plz don't look too closely ).

a holesaw made life easy on the covers ).

a holesaw made life easy on the covers

sumthin like this........ready for set up on the motor, then brazing

out of time again

[ Edited on 5-6-07 by dumone ]

|

|

|

Dasdubber Dasdubber

A.k.a.: Alan Agyik

23 Windows of Awesome

DAS Resto Haus

Posts: 5746

Threads: 289

Registered: August 26th, 2002

Member Is Offline

Location: Gold Coast

Theme: UltimaBB Pro Blue

Mood: feeling fine...

|

| posted on June 5th, 2007 at 07:52 PM |

|

|

Keep plugging away Daimo - enjoying your progress as usual!

|

|

|

VWCOOL VWCOOL

23 Windows of Awesome

Posts: 5158

Threads: 235

Registered: June 19th, 2003

Member Is Offline

Location: In the shed... Lake Macquarie NSW

Theme: UltimaBB Pro Blue ( Default )

Mood: happy to help

|

| posted on June 6th, 2007 at 10:14 AM |

|

|

Um, don't shoot the messenger but I think you may have a problem with oil running up into the rocker area; drain-backs must be above 'high tide

mark' in the sump

Pay your debts, CxxT

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on June 6th, 2007 at 10:00 PM |

|

|

it's cool M8,when your sump is about to run dry, they are

seriously tho, it's nothing new Glenn, it's been done successfully before........

http://www.clubvw.org.au/Inch%20by%20Inch.htm

INCH BY INCH

Hellbug's Jeff Unwin takes us through what it took to squeeze a few extra seconds of performance out of his racing beetle

It had been two and a half years since we had turned a wheel in anger in the mighty little beetle and i was itching to get back into hillclimbing.

The CAMS newsletter had arrived in the mail and there was an item on the upcoming Australian Hillclimb Championships at Grafton in six and a half

weeks and not being one to procrastinate, the decision was made then and there to go for it! The only problem being that companion Jo Smith's car had

sustained a huge prang at Bathurst back in 1990 and desperately needed some attention. On that occasion, the fan had exploded at 8000 rev's, taken

out the accelerator cable tube and jammed the Dellorto's flat out as she was approaching The Dipper.

Well, what can i say, fate was really kind not to roll her over. (the car that is) so there was no body damage but three corners of the suspension

were badly bent and the right hand front shock tower had put a 50mm deep dent into the inner guard.

The car had then been retired to a relative's farm at Binnaway, and suffered the indignity of sitting in a barn there and accumulating a solid layer

of bird poo while it sat forlornly in the the farm shed. I took a quick trip to Binnaway one day and loaded the very bent bug onto a trailer and then

took it home the next day- all without incident. I was very lucky to have three untiring helpers in the form of James McKinnon, Grant Camper and

Shimo.

Previously we had raced the "Bug out of Hell" in the road registered class and later as a sports sedan. Times had changed however and with the

introduction of the group 2E Silhouette Class i,e 60 series tyres, no 'glass guards and a maximum seven inch rim size for cars up to 3000cc.

This formula posed a couple of problems. Firstly our old gearing was too tall (the 3.88:1 diff, 3.4:1 1st, 2.21:1 2nd, 1.48:1 3rd and 1.125:1 top were

nowhere near close enough) and secondly, we had no 60-series tyres because back in the '80s we used 50-series.

As it turned out we had bought and old drag race gearbox earlier in the year, so we had a few extra ratios to choose from (this included 4.375:1 ring

and pinion and 3.8:1, 2.06:1, 1.58:1 and 1.21:1 gears). In the end we came up with a great little close ratio 'box using the 4.375:1 diff gears and

3.4:1, 2.21:1, 1.58:1 and 1.21:1 gear ratios which worked in really well with the 205-60X15 tyres.

There was a huge list of chores to complete before we headed to Grafton. This included stealing the front end out of the old race car, replacing wheel

bearings, tie rod ends, ball joints and control arms, recondition the calipers and fit new metal pads. other tasks undertaken including replacing

steering coupler and dampner, fitting a race seat, harness and half cage.

Next we rebuilt the entire rear end, bushes and breaks and then stripped down several gear boxes to salvage the required parts to make up one good

unit.

The 1904cc motor was stripped and freshed up ready to be raced. We then went over to Eastcoast suspension for a 4 wheel allignment and then back home

to fit the sway bars ( 20mm front and 22mm rear ).

We then packed up all the spares and headed off for Grafton ( a day before practice started Jamo and Grant drove up and met me there on Thursday

morning )

Grafton's track had been lengthened, resurfaced and was alot tighter than what I could remember from 5 years earlier so I had the car scrutineered

early to be one of the first cars out onto the track. Even though the track was a bit green ( leaves and branches littered the track and no rubber had

yet been laid down ) , I was still quite happy with how the borrowed rubber was gripping. I was only about 3 seconds off the old record.

A quick check of the tyre pressures and off I went again, this time really getting the feel back again and throwing the car around like a Formula one

car when suddenly the oil light came on. I turned it straight off and coasted down the return road. When we pulled the Oberg filter apart there were

parts of a big end bearing straing at me. It appeared that we should have put the oil surge gates back in from our old Hellbug motor as now the sticky

tyres were generating the same G-forces as the soft slicks I ran before.

There was a fair bit of dissappointment in the camp. In fact, Grant and Jamo were shattered. I ended up driving to Kempsey, taking a 1916cc motor out

of a buggy and fitting up our Webers. But alas the off-road motor had an inappropriate cam and didnt really go. We managed a last-in-class finish and

the distinction at being the only vehicle unable to spin the wheels off the start line. At this stage I must thank Mark and Luke Pell for their help

with all our problems over that weekend. It was their motor that was so generously lent to me.

BACK TO THE OLD DRAWING BOARD

Not to be put off by such small hassles I had the motor rebuilt in 2 weeks ( this time with all the baffling in the sump ). And competed in the show

and climb at Canberra winning the class, being 2nd outright and the fastest Group 2E bug. Now we were cooking and competed in 5 more 'climbs before

Christmas managing class wins in each of. So the poor little motor was owed a bit of work by the time the years racing was complete.

Upon this assembly some very interesting observations were made: 1: The tunnel of the case had worn out allowing the centre main bearing to move and

the crankshaft to flex. 2: Some evidence of oil starvation was still present in rod bearings #1 and #4 and: 3: The breather system had not been

adequate because the 2.0-litre catch-tank was always filling with oil at the end of each days racing.

After a meeting with Shimmo and Peter Gonad, a complete revamp of the breathing and oil system commenced. This was a two-pronged attack to ensure that

I had adequate breathing as well as adequate oil in the pick-up area (deep sump centre ).

I had purchased a late-model AS21 fuel injection case ( with the huge oil galleries throughout ) from Gene Berg in 1989 as a back-up for the 2213cc

motor. This already had all the machining done, i.e. decked , bored for 90.5mm barrels, fully flowed, 8mm case stud nut lands spot-faced for the 15mm

head nut conversion and die ground to fit a Washington Antishocker.

To increase the breathing of the internals, a 32mm hole was machined where the fuel pump hole should have been ( PI* case remember! ) I then

fabricated a baffled breather tube and fitted a motorcycle air cleaner to stop dust getting in.

The rocket cover breathers were increased from 3/8" i.d to 3/4" i.d and a small baffle plate brazed over the breather outlet hole on the cover. This

then necessitated enlarging the breather pipes on the Berg breather box-cum-oil-air filter to take the larger hose. Another motor cycle air filter was

used on top of the Berg breather to stop any restriction in the system.

As far as oiling went this was somewhat more perplexing and a lot of testing and rethinking was needed before the final tolerances was initiated. A

deep sump already had a quadrangle set-up with flapper valves so that the oil in the sump could only find its way from the four outer corners into the

central pick-up area. The only thing that could possibly stuff this up would be if the oil wasnt returning to the sump fast enough.

As the oil pressure had always been adequate ( when the oil was there to suck up ) at 700kpa at 7000rpm with a 30mm Berg pump. When fitting a larger

oil pump you not only get a higher pressure but also a much larger volume. therefore, if we cut down the volume being pumped then it will take longer

to drain the 3.5 litres in the sump giving us a few extra seconds of supply before we run dry. A 26mm very plugged oil pump was fitted as a result of

this logic.

How to get more oil into the deep sump?

Once again a two-pronged attack was required. A new oil pick up was bent with open flowing bands so that there was no added weld-on parts that picked

up the oil in the sump. The hood that normally went over the oil strainer area was also not used so that the oil in the engine sump had a much larger

area to fall through.

As I always ran the oil level at the top mark of the dip stick and already used windage push rod tubes, the premise was that a fair bit of oil was

sitting in the rocker cover area ( because we could not stop the oil from running up the push rod tubes on very hard cornering ) A quick look at Col

Matthews' porsche to see what "Big Brother" was using gave us the answer. Two 0.75in. oil returns were fabricated on the bottom of each rocker

cover going straight down into the top of each of the sumps four corners. Voila!

As it turned out this system has worked perfectly with the main bearings and CAM bearings being only changed annually and the rod bearings at half

yearly intervals.

Now that the engine reliability problems had been solved we went about a full revamp of the steering and suspension set ups. Its funny how the fickle

finger of fate changes from the "you beaut" thumbs up of success to the heavenly - pointed middle finger of dispair in a matter of seconds.

friday nights trip to the first rund of the Hillclimb Championships at Bathurst was miserable weather, rain, sleet, fog - everything you'd expect

going to Bathurst. When we got to the top of River Lett Hill doing about 80 clicks around an 80-rated corner while flat-towing the bug on an A-frame

behind the ute, I felt the tail of the ute come out. After a big correction I thought I'd saved it only then to pirouette 360 degrees followed by a

180-degree turnaroundand finish up against an embankment. In the olympics that stunt would have gained me a series of 9.5's from the judges as it was

all we achieved was some battered suspension and sheetmetal.

The left-hand front wheel from Joe's carhad come around and hit the left-hand rear wheel of the ute. I had to disconnect the buckled A-frame and flat

tow the Beetle into Bathurst with a wire sling. By ten the next morning we had a wheel alignment done, tyres changed over to some non-buckled wheels

and a trip to the panel beater to have the bumper and damaged guard knocked out so that I could race.

Meanwhile, the right-hand rear trailing arm was still bent with 2.5 degrees positive camber instead of 1.5 negative, but we still managed to take the

class win and set a new record on the day.

This little last adventure was probably the main turning point that helped me change the handling set-up of the car forever. As the beam was bent a

tad I did the first of our camber restorations on the top arms and dialled in a two-degree negative per side and the car loved it.

I then got to thinking, "How much negative camber can a Beetle take before it gets totally out of hand?"

They say nothing improves the breed like racing and after one full year of Hillclimbing I now have all the formulas for setting up and making a car

handle straight out of the box. By "handle" I mean being able to take on just about any street car on the road today and wave goodbye to them when

you come to corners. We atarted off the year 35th outright at Bathurst and peaked at 10th outright at Huntley in 1993 and to say the team is having a

ball is an understatement.

Once the handling and braking has been taken care of you can then concentrate on more engine development. The motor now sports 44 x 37.5 Berg race

heads and extensively modified ( by Henry Spicak ) 48mm Webers. The big change for 1994 had beenthe fitting of a GB 315 ( FK87 ) camshaft as opposed

to the old GB311 ( K10 ) on the 112 lobe centres which were set-up retarded.

This one change took .6-second off our eighth mile drag racing times ( 8.9 to 8.3- sec ) and added 9km/h to the terminal speed.

This yarn is being written just before Parkes Hillclimb championship round, so the motor is once again apart but more for a freshen up and re cam to a

GB 316 ( FK 89 ).

All these changes have made the Bridgestone 610s unable to cope so a change to gumball Dunlop 78Js should help us to stick. And it will keep on going

like this, trying to screw that extra little bit out of the Bug. Because one day it would be nice to go to South Australia to run the class at the

Australian Hillclimb Championships and then blow all those twin cam Datsuns away.

We work on the theory that the harder you work the luckier you get.

|

|

|

VWCOOL VWCOOL

23 Windows of Awesome

Posts: 5158

Threads: 235

Registered: June 19th, 2003

Member Is Offline

Location: In the shed... Lake Macquarie NSW

Theme: UltimaBB Pro Blue ( Default )

Mood: happy to help

|

| posted on June 6th, 2007 at 11:59 PM |

|

|

yeah, I remember that from Jeff's car a while back, but Jeff's car appeared fumy. Could this have possibly been due to surge of oil UP the

drain-back pipes and leaking out the rocker gaskets?

Is there any way you could fit some sort of flapper/one-way valve in the tubes?

[ Edited on 7-6-2007 by VWCOOL ]

Pay your debts, CxxT

|

|

|

johny rotten johny rotten

Officially Full-On Dubber

Posts: 366

Threads: 5

Registered: April 6th, 2004

Member Is Offline

Theme: UltimaBB Pro Blue ( Default )

|

| posted on June 7th, 2007 at 10:18 AM |

|

|

Blahh

Quote Glen T..............And Jeff's car always was 'fumy'...

end Quote

WTF thats suppose to mean Glen ?

I think your fuming at the mouth again.

[ Edited on 7-6-2007 by johny rotten ]

|

|

|

555bug 555bug

Custom Title Time!

WRX Bug Boy

Posts: 1123

Threads: 79

Registered: August 26th, 2002

Member Is Offline

Location: Brisbane

Theme: UltimaBB Vintage

Mood: turbo charged

|

| posted on June 7th, 2007 at 08:54 PM |

|

|

1) top job

2) what sort of compressor do you have that lets you port for such long periods?

3) any advice on carbide bits after your 100's of hours?

hope it goes like stink

Stephen |

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on June 18th, 2007 at 06:34 PM |

|

|

thanx.

to answer your questions.......

a bloody great big 3 phase compressor at 120psi. i was a bit worried today when it didn't need to "top up" for 1/2 an hour, thought it was

broken .... ....

carbide burrs.....i like the ones with rounded tips as they don't leave big edges. you can take a lot of material out with flapper wheels which are

relatively easy going. turn your rotary grinder down so it runs slowly at full throttle.ear muffs, safety glasses and lots of clothing.

don't try and use a bit that makes a particular job hard/risky, if you can, stop and swap it for a more suitable one from your selection  .......... ..........

it should run strong.........if it doesn't...........it's nothing EFI, turbo and intercooling won't fix

[ Edited on 18-6-07 by dumone ]

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on June 18th, 2007 at 07:03 PM |

|

|

VWCOOL

i hear what your saying. looked at non return valves, nothing off the shelf that i found for it. many schemes have been nutted about

the fittings in the sump protrude well into it so oil doesn't flow up the walls and into them. the return side of fittings are "ported" to a knife

edge. as are the openings in the rocker covers

i'm finding the starvation (oil light on) is happening as i come out of the corners and approach full revs for the first time, not in the middle of

the corner (maybe this relates to my driving style). i'm using windage pushrod tubes allready, so the thoughts are that the oil is running up to the

rocker area via the pushrod tubes despite. as i reach full engine noise after/in the corners the LAST REMAING oil in the sump gets pumped

away..........because the oil still gathered up in the rocker covers has not got a direct/quick enough return to the oil pick up area.......

so if we can get ANY more oil back to the sump before it goes dry, it may just be enough to keep pressure for that second or two until the cornering

subsides and oil is again gathering at the pick up tube area.

i might baffle the sump or lines yet.....maybe just borrow Jeffs

yes it's a hard one to get round in ya brain.

it's done now....we will see.....

the 1/2 inch oil fitting was drilled out as large as possible to help breathing too

clearance is good......not too much.not too 'lil:thumb

theres not much choice for where the returns go....

getting around the exhaust and tin wear would be difficult

SPAGHETTI

it's all tucked up above sump level tho.......

[ Edited on 18-6-07 by dumone ]

|

|

|

bond bond

Veteran Volks Folk

Posts: 2456

Threads: 166

Registered: July 11th, 2003

Member Is Offline

Location: brisbane

Theme: UltimaBB Pro Blue ( Default )

|

| posted on June 18th, 2007 at 08:55 PM |

|

|

looks the goods man! question - will the piping between the tappet covers and the sump require fastening with s/s clamps to the fittings? is it under

much pressure?

nick

|

|

|

hellbugged hellbugged

A.k.a.: Daimo Pell

23 Windows of Awesome

48's and straight cuts

Posts: 5080

Threads: 116

Registered: April 17th, 2003

Member Is Offline

Location: Nambucca Valley NSW

Theme: UltimaBB Psyche Blue

Mood: Couldn't care less

|

| posted on June 18th, 2007 at 09:27 PM |

|

|

yes there will be hose clamps at both ends.

there is no pressure at all, simply 3/4 inch gravity fed return lines. an alternative route for returning oil aside from the pushrod tubes.

|

|

|

| Pages: 1 .. 4 5 6 7 8 .. 24 |